Overview of Aluminum Parts Welding Process

Overview of Aluminum Parts Welding Process

- Customized

- Aluminum Parts Welding

- Customized

- Informations

- Description

Overview of Aluminum Parts Welding Process

Overview of Aluminum Parts Welding Process

Mastering Precision in Aluminum Fabrication

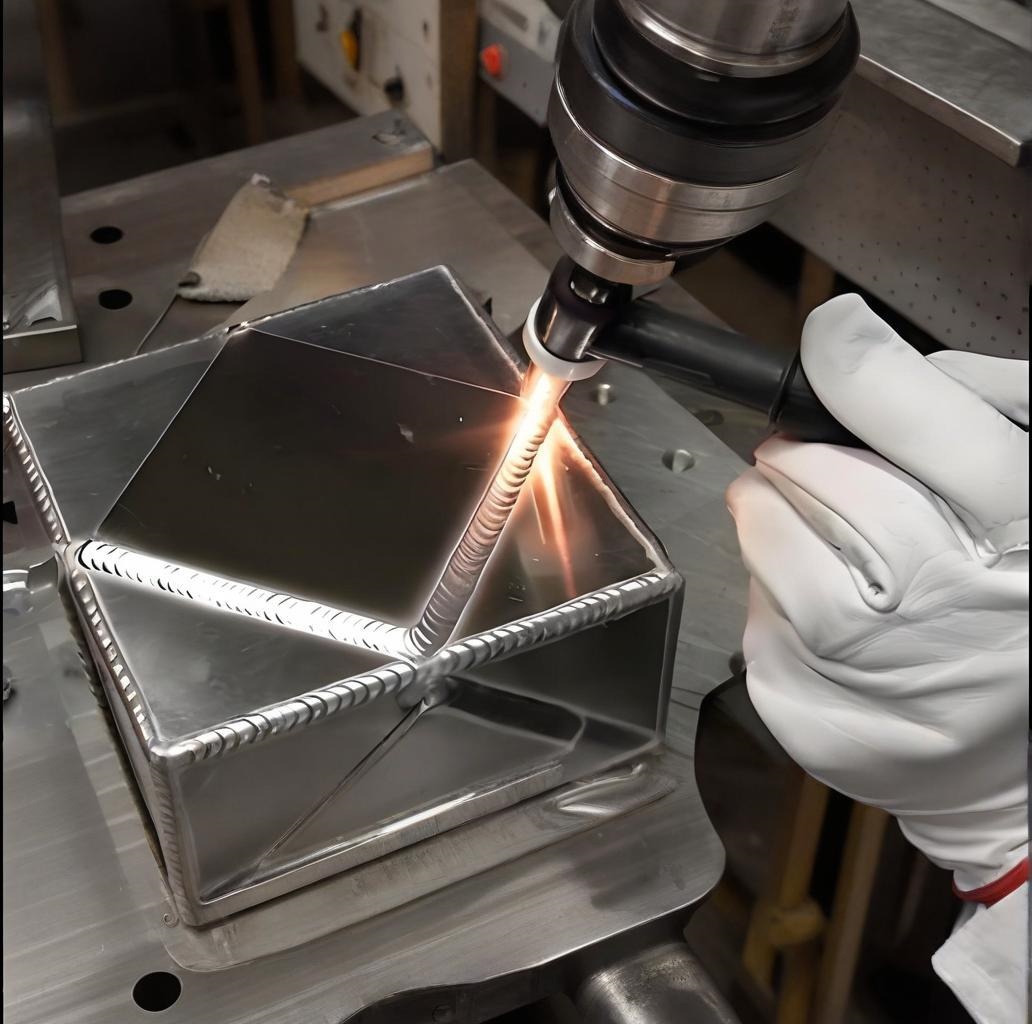

Aluminum parts welding stands as a cornerstone of our manufacturing expertise, combining technical precision with material science to create durable components. This process involves fusing aluminum alloys through heat and pressure, tailored to meet diverse industrial requirements.

Core Welding Processes We Employ

Welding Method | Key Features | Application Scenarios |

TIG (TIG Welding) | • High arc stability• Precision control• Suitable for thin sheets | Aerospace components, medical devices |

MIG (MIG Welding) | • High deposition rate• Automatic wire feeding• Ideal for thick materials | Automotive parts, structural frames |

Gas Welding | • Portable equipment• No electricity needed• Suited for on-site repairs | Construction, remote projects |

Process Flow

Material Preparation: Surface cleaning to remove oxide layers and debris.

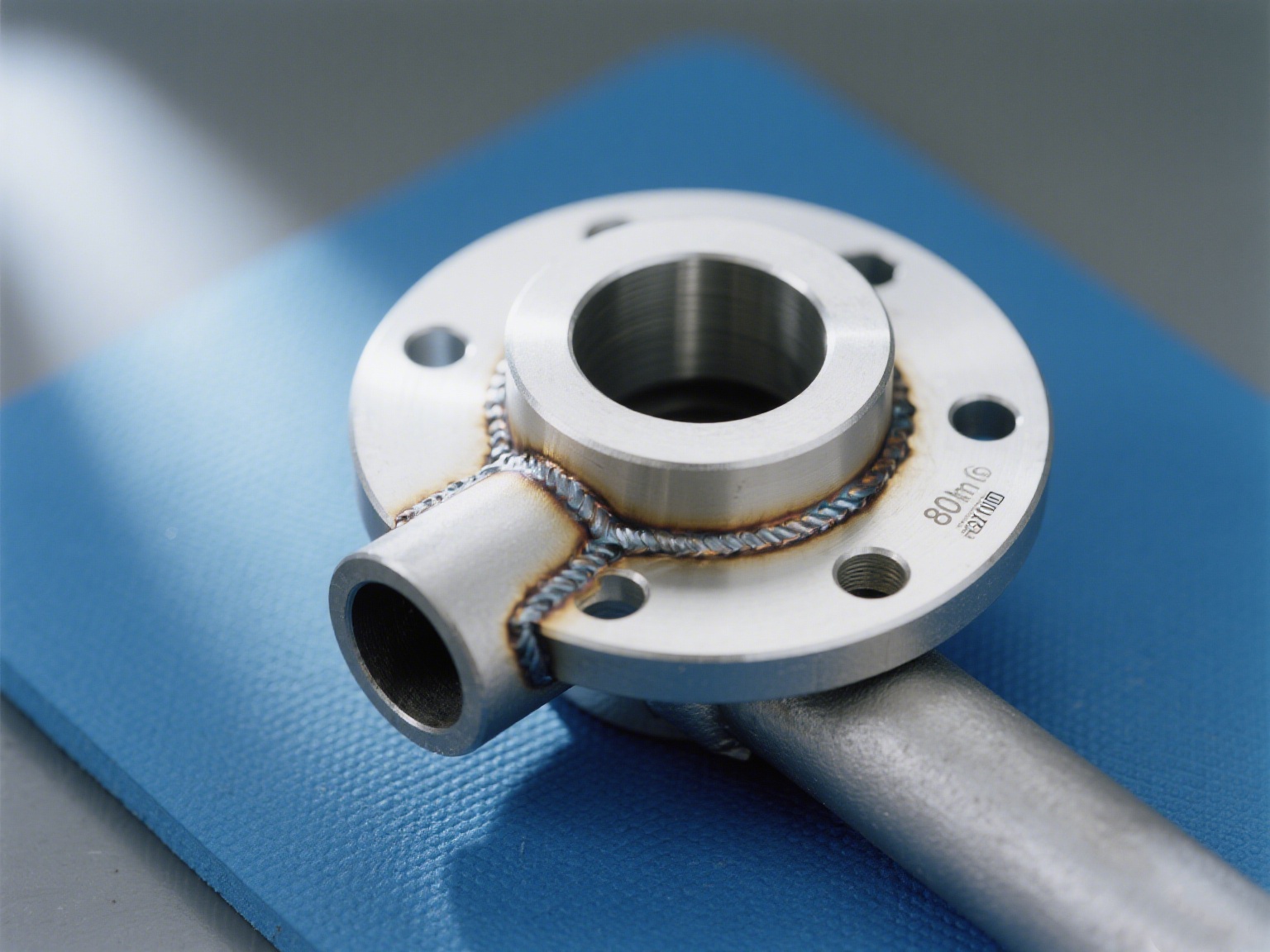

Joint Design: Customized for strength, including butt, lap, or T-joints.

Welding Execution: Precision heat application with inert gas shielding.

Post-Weld Treatment: Stress relief and surface finishing for optimal performance.

By integrating advanced techniques with strict quality control, we ensure every weld meets international standards for durability and consistency.

| Type | Aluminum Parts Welding | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)