How to Weld Aluminum

How to Weld Aluminum: A Comprehensive Step-by-Step Guide

- Customized

- Aluminum Welding

- Customized

- Informations

- Description

How to Weld Aluminum: A Comprehensive Step-by-Step Guide

How to Weld Aluminum: A Comprehensive Step-by-Step Guide

Step-by-Step Welding Process

1. Material Preparation & Surface Treatment

Cleaning Protocol: Remove oil, debris, and the natural oxide layer using:

Stainless steel wire brush (avoid steel to prevent contamination)

Solvent cleaning with acetone or specialized aluminum degreaser

Joint Design Options:

Joint Type | Suitability | Strength Rating |

Butt Joint | Flat surfaces, thin materials | High (when properly aligned) |

Lap Joint | Overlapping sheets, added stability | Medium to High |

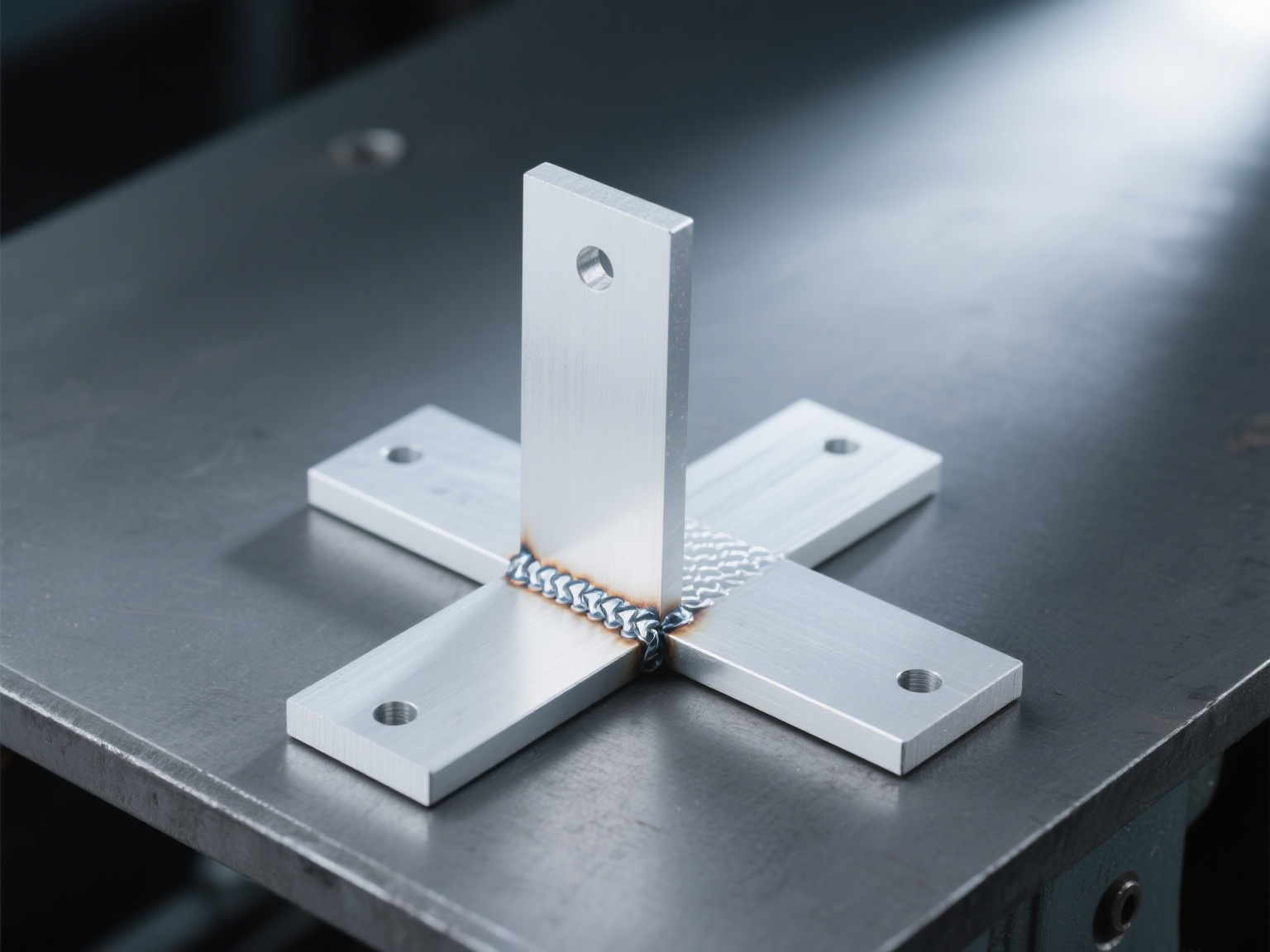

T-Joint | Structural intersections | Medium (requires proper fillet weld) |

2. Equipment & Welding Method Selection

Core Welding Techniques We Utilize:

Welding Method | Equipment Required | Process Advantages | Ideal Thickness Range |

TIG (Tungsten Inert Gas) | TIG welder, tungsten electrode, argon gas | • Precision control for intricate parts• Clean weld beads with minimal spatter | 0.5mm – 6mm |

MIG (Metal Inert Gas) | MIG welder, aluminum filler wire, shielding gas (argon or argon-helium mix) | • High deposition rate for fast production• Semi-automatic wire feed reduces operator fatigue | 1mm – 12mm |

Gas Welding (Oxy-Acetylene) | Gas cylinders, welding torch, aluminum flux | • Portable for on-site repairs• Cost-effective for low-volume projects | 0.8mm – 4mm |

3. Welding Execution Best Practices

Gas Shielding: Use 99.99% pure argon for TIG/MIG welding to prevent oxidation.

Filler Metal Selection:

Alloy Type | Application | Filler Wire Recommendation |

6061/6063 | General fabrication, automotive | 4043 (silicon-based, high fluidity) |

5052 | Marine, corrosion-resistant parts | 5356 (magnesium-based, matching corrosion resistance) |

2024 | Aerospace, high-strength components | 2319 (heat-treatable alloy for critical applications) |

Heat Control:

Preheat thick sections (100–150°C) to reduce thermal stress.

Use a pyrometer to monitor temperature and avoid overheating.

4. Post-Weld Treatment & Quality Assurance

Cleaning: Remove flux residues with warm water and mild detergent (critical for MIG/gas welding).

Inspection Methods:

Technique | Purpose | Detection Capability |

Visual Inspection | Surface defects | Cracks, porosity, incomplete fusion |

Dye Penetrant Testing | Subsurface flaws | Micro-cracks in non-porous materials |

X-Ray Radiography | Internal defects | Porosity, slag inclusions in thick sections |

Advantages of Our Aluminum Welding Services

Key Advantage | Technical Explanation | Industrial Impact | Case Study Example |

Lightweight Strength | Welded 6061-T6 aluminum maintains 90% of base metal strength | Reduces aircraft component weight by 25% | Airbus A350 wing ribs project |

Corrosion Resistance | Oxide layer re-forms naturally on welds | Extends marine component lifespan by 300% | Offshore platform brackets |

Thermal & Electrical Conductivity | Welded joints retain high conductivity | Efficient heat sinks for EV battery packs | Tesla Model 3 battery cooling systems |

Cost Efficiency | Aluminum costs 30–50% less than steel per unit volume | Reduces automotive chassis production costs by 20% | Major OEM truck frame project |

Distinctive Technical Features of Our Expertise

Feature | Implementation | Client Benefit | Quality Standard |

Oxide Layer Management | Pre-weld plasma cleaning + flux-cored wire for MIG | 99.9% oxide removal, eliminating weak welds | ISO 15614-2:2019 |

Dual-Gas Shielding | Argon-helium mix for MIG welding thick sections | 40% faster heat input with reduced distortion | AWS D1.2:2021 |

Robotic Welding Systems | Fanuc robots for high-volume parts | ±0.1mm weld precision, 99.7% repeatability | AS9100D certified |

Post-Weld Stress Relieving | Thermal cycling in controlled ovens | Reduces residual stress by 85%, prevents cracking | Nadcap-accredited process |

Industry-Specific Welding Solutions

Sector | Critical Requirements | Our Specialized Approach | Notable Projects |

Aerospace | High-purity welds, NDT compliance | TIG welding with helium back purging | Boeing 787 fuselage panels |

Automotive | High-speed production, weight optimization | Robotic MIG with pulsed current | BMW i-series electric vehicle frames |

Electronics | Micro-welding, thermal management | Laser welding for 0.1mm-thick heat sinks | Apple MacBook Pro cooling systems |

Construction | Structural integrity, weather resistance | Submerged arc welding for extrusions | Burj Khalifa architectural elements |

| Type | Aluminum Welding | Entrance size | Customized |