How to Gas Weld Aluminum

How to Gas Weld Aluminum

- Customized

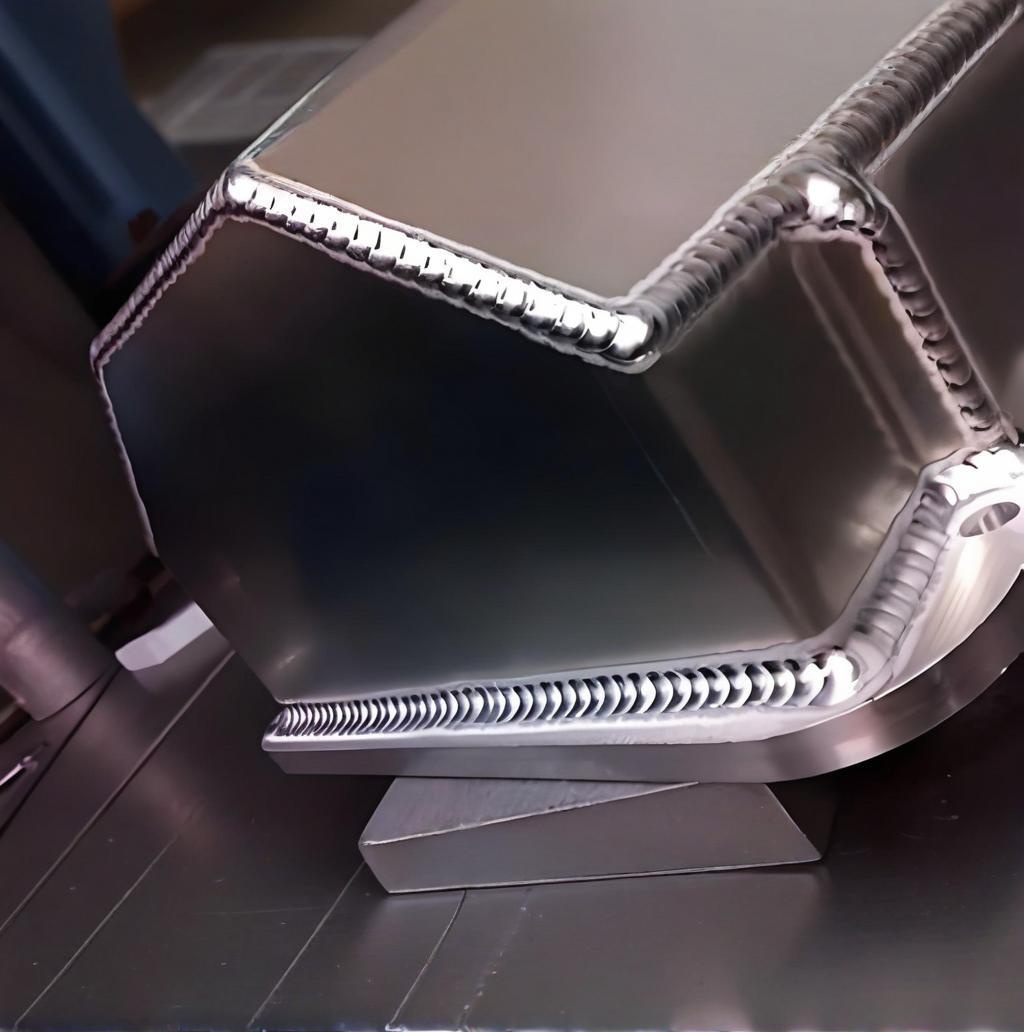

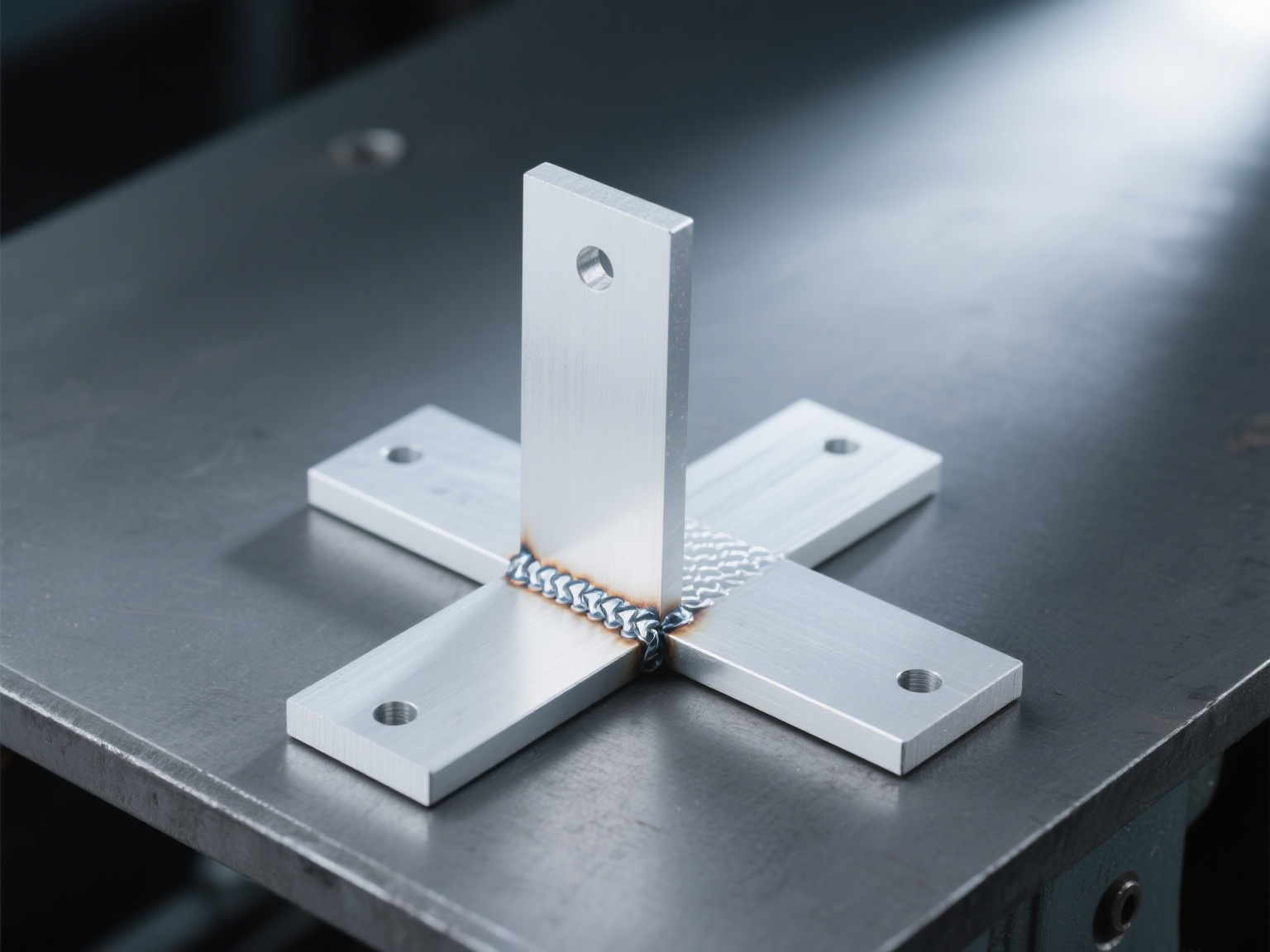

- Aluminum Parts Welding

- Customized

- Informations

- Description

How to Gas Weld Aluminum

How to Gas Weld Aluminum – A Step-by-Step Guide for Crafting Robust Welds

Why Choose Gas Welding for Aluminum?

Cost-Effective Equipment – Compared to TIG or MIG setups, gas welding requires simpler, more budget-friendly tools, making it accessible for hobbyists and professionals alike.

Portability – The compact nature of gas welding equipment allows for easy transportation, making it ideal for on-site repairs, outdoor projects, or work in remote locations.

Suitability for Thin Gauges – When executed properly, gas welding produces smooth, precise welds on thin aluminum sheets without causing excessive heat distortion.

No Electrical Dependence – Unlike its electric counterparts, gas welding operates independently of power sources, offering unparalleled flexibility in areas with limited or no electricity.

The Welding Challenges of Aluminum

Oxide Layer Complexity

Thermal Conductivity Challenges

Low Melting Point Vulnerability

Porosity Risks

Grasping these inherent challenges is essential for implementing targeted precautions—only then can you achieve welds that meet the highest standards of strength and durability.

Tools and Materials Needed

Before starting, gather the necessary tools and materials for gas welding aluminum. Here’s what you’ll need:

Item Purpose Oxygen-acetylene torch Provides the heat required for welding Aluminum welding rods (4045 or 1100 series) Filler material to create strong welds Flux (suitable for aluminum) Removes the oxide layer for better bonding Wire brush (stainless steel) Cleans aluminum before welding Heat-resistant gloves Protects hands from burns Safety glasses or welding goggles Shields eyes from bright light and flying debris Fire-resistant welding jacket Prevents burns from sparks and heat Acetone or alcohol Cleans the aluminum surface before welding

Having the right materials makes a big difference in how well the weld turns out.

Preparing Aluminum for Gas Welding

Proper preparation is crucial when gas welding aluminum. If the surface isn’t cleaned and prepped correctly, the weld will be weak and full of defects.

Clean the Aluminum Surface

Aluminum must be free of dirt, grease, and oxidation before welding. Use acetone or alcohol to remove grease, then scrub the surface with a stainless steel wire brush to remove the oxide layer.

Apply Flux

Since aluminum forms an oxide layer quickly, applying flux is essential. Flux helps break down the oxide layer, allowing the filler metal to bond properly. Brush or dip the filler rod in flux before welding.

Preheat the Aluminum (If Needed)

For thicker aluminum, preheating helps reduce thermal shock and improves weld quality. You can use a torch to gently preheat the area, but avoid overheating, as aluminum melts quickly.

How to Gas Weld Aluminum

Now that everything is prepped, it’s time to start welding. Gas welding aluminum requires precise control of heat and movement.

Adjust the Torch Flame

Set up the oxygen-acetylene torch with a neutral flame. A neutral flame has equal amounts of oxygen and acetylene, producing a clean, blue flame with no excess carbon or oxygen. Avoid using a carburizing or oxidizing flame, as these can weaken the weld.

Heat the Aluminum Evenly

Move the flame in a circular motion over the area to be welded. Since aluminum conducts heat quickly, be patient and allow the metal to reach the right temperature before adding filler material.

Introduce the Filler Rod

Once the aluminum is hot enough, dip the filler rod into the molten puddle. The filler should flow smoothly into the joint. If the metal isn’t melting properly, adjust the torch position slightly or apply more flux.

Maintain a Steady Motion

Keep the torch and filler rod moving in a steady, controlled manner. If you pause too long, you risk overheating and burning through the aluminum. Practice maintaining a smooth, consistent movement.

Let the Weld Cool Naturally

After completing the weld, allow it to cool naturally. Rapid cooling can lead to cracking, so avoid using water or compressed air to speed up the process.

Common Mistakes and How to Avoid Them

Many beginners struggle with gas welding aluminum because of a few common mistakes. Here’s how to avoid them:

Mistake Problem Solution Not cleaning the surface properly Weak or contaminated welds Always remove oxide and grease before welding Using the wrong flame setting Excess oxidation or weak bonds Always use a neutral flame Overheating the metal Burn-through or warping Apply heat gradually and avoid excessive torch time Not using flux Poor filler rod bonding Always use the correct aluminum flux Moving too fast or too slow Inconsistent welds Maintain a steady, even pace

Avoiding these mistakes will make a big difference in the strength and appearance of your welds.

Gas welding aluminum may not be the easiest process to learn, but it’s a valuable skill that can save you money and expand your welding capabilities. With the right preparation, proper flux, and steady heat control, you can create strong, clean welds.

I’ve worked with aluminum welding for a while now, and I can tell you that patience and practice are key. If you struggle at first, don’t get discouraged. Keep refining your technique, and soon you’ll be able to weld aluminum confidently.

If you work with aluminum regularly, mastering gas welding can give you more flexibility for different projects. And best of all, once you get the hang of it, you’ll be able to fix, build, and modify aluminum parts without relying on expensive welding machines.

| Type | Aluminum Parts Welding | Entrance size | Customized |