Aluminum Welding: Explore Our Diverse Techniques & Their Advantages

The aluminum welded products displayed on our webpage are more than just finished parts—they’re the result of choosing the right welding technique for the job. We offer a range of specialized aluminum welding methods, each with unique strengths to match your project’s needs. Let’s break down the key differences and advantages of our core services.

TIG Welding (Tungsten Inert Gas)

What it is: A precise, manual process using a non-consumable tungsten electrode to create the weld, with a separate filler metal added as needed. Shielding gas (typically argon) protects the weld pool from contamination.

Best for: Thin aluminum sheets, intricate designs, and projects requiring flawless aesthetics (e.g., visible components, custom parts).

Advantages:

Exceptional precision, ideal for tight tolerances (matching the ±0.1mm weld seam straightness in our standards).

Clean, spatter-free welds that require minimal post-processing.

Works well with high-strength aluminum alloys, maintaining 90%+ of base metal strength in joints.

What it is: An automated or semi-automated process where a consumable wire acts as both electrode and filler, fed continuously through a welding gun. Shielding gas (argon or argon mixtures) safeguards the weld.

Best for: Thick aluminum sections, high-volume production, and structural components (e.g., industrial frames, large assemblies).

Advantages:

Faster than TIG, making it cost-effective for bulk projects.

High deposition rates, ideal for joining thick materials efficiently.

Robust welds with strong mechanical properties, perfect for load-bearing parts.

What it is: A high-tech method using a focused laser beam to melt and fuse aluminum, with minimal heat input.

Best for: Micro-welding, complex geometries, and heat-sensitive components (e.g., electronics enclosures, precision machinery parts).

Advantages:

Ultra-narrow heat-affected zone (HAZ ≤1mm, even smaller than our standard ≤2mm), reducing distortion in thin or delicate parts.

Extremely fast welding speeds for small, repetitive joints.

Consistent results across high-precision applications, with surface roughness as low as Ra 0.8μm.

The choice depends on your project’s size, design complexity, and performance needs. TIG shines for beauty and precision, MIG excels in speed and strength for large-scale work, and laser welding leads in micro-precision. All our techniques meet or exceed industry averages—for example, our MIG welds still achieve 85%+ base metal strength, while laser welding’s minimal HAZ outperforms traditional methods by 60%.

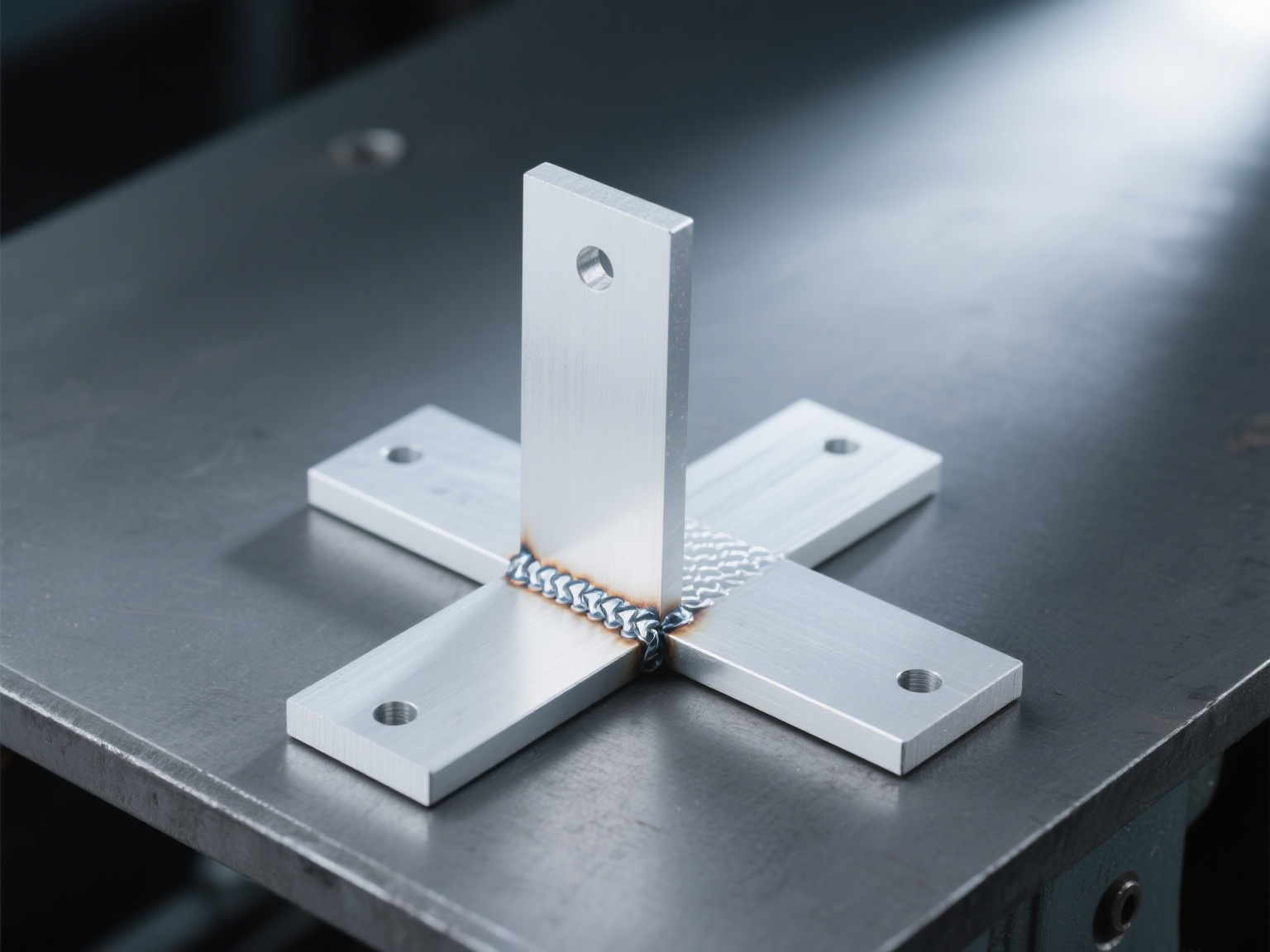

The aluminum welded products in our photos showcase these techniques in action: the smooth curves of a TIG-welded custom bracket, the sturdy seams of a MIG-welded industrial frame, and the tiny, precise joins of a laser-welded component.

Ready to pick the perfect welding method for your aluminum parts? Contact us today to discuss your project details—we’ll help you choose the technique that balances precision, strength, and efficiency, ensuring results as impressive as the products you see.

|

Type

|

Aluminum parts welding |

Entrance size

|

Customized at your needs |

![]()