Aluminum Stamping: Crafting the Future of Lightweight Manufacturing

Aluminum Stamping: Crafting the Future of Lightweight Manufacturing

- Customized at your needs

- Aluminum Stamping

- Customized at your needs

- Informations

- Description

Aluminum Stamping: Crafting the Future of Lightweight Manufacturing

Aluminum Stamping: Crafting the Future of Lightweight Manufacturing

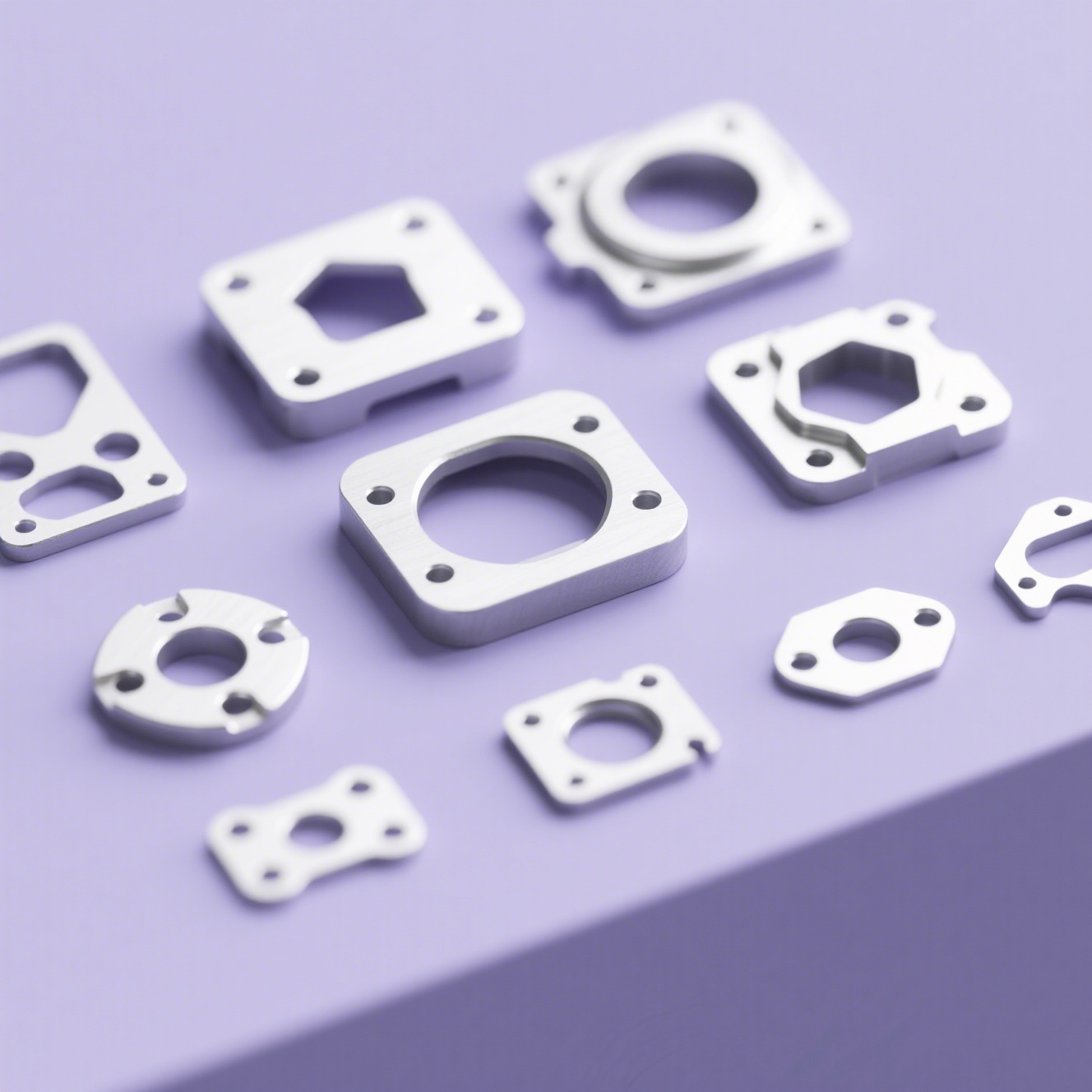

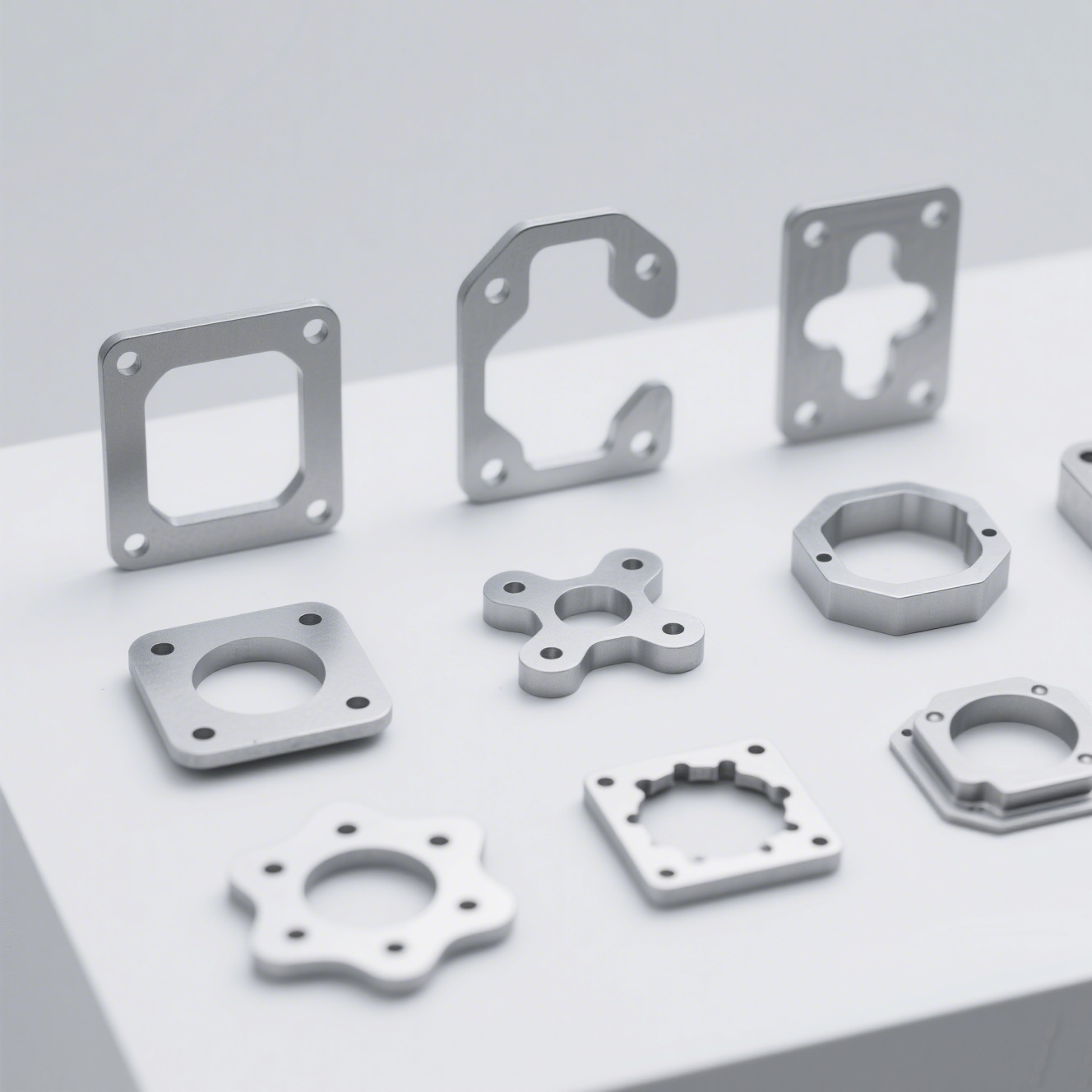

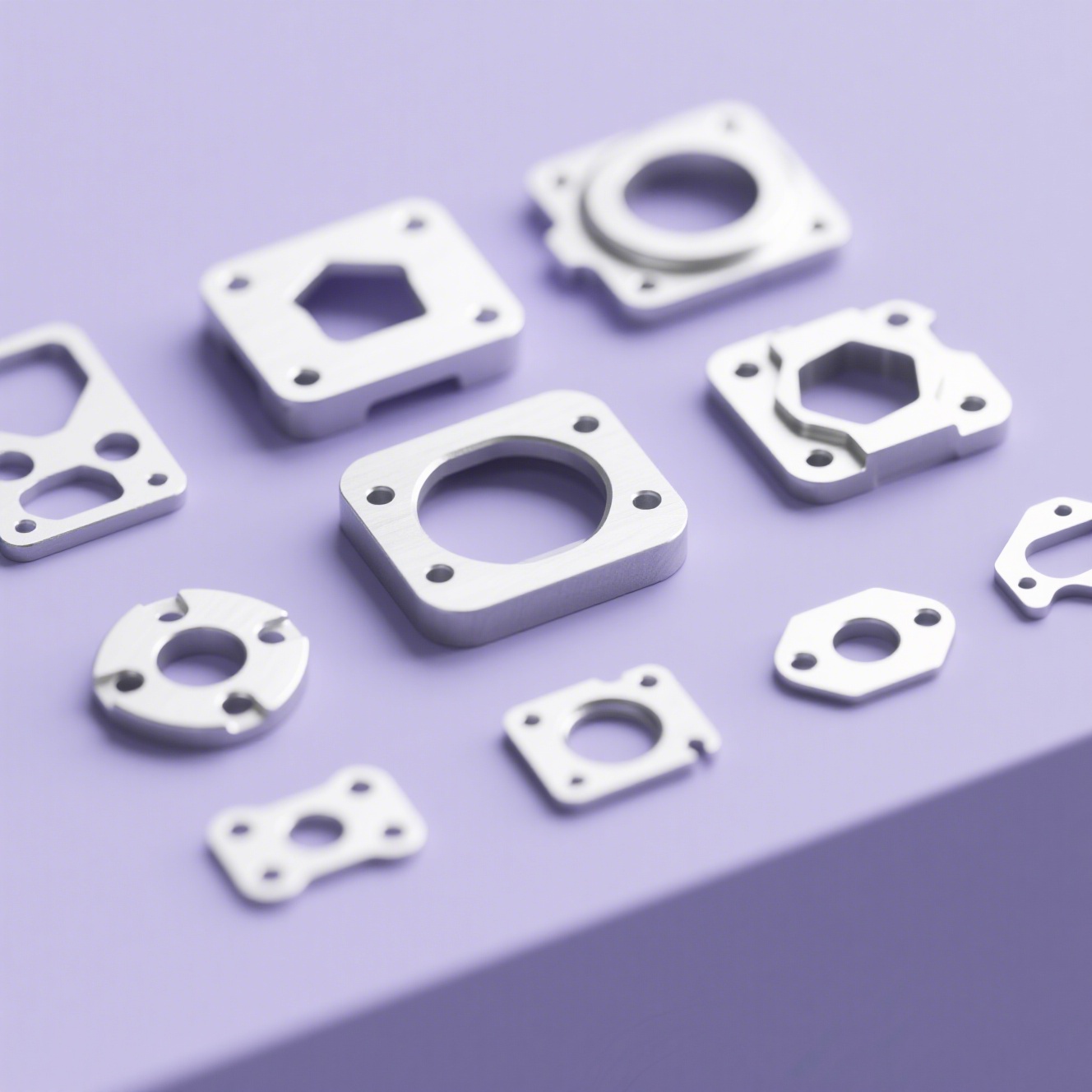

1. The Art of Aluminum Stamping

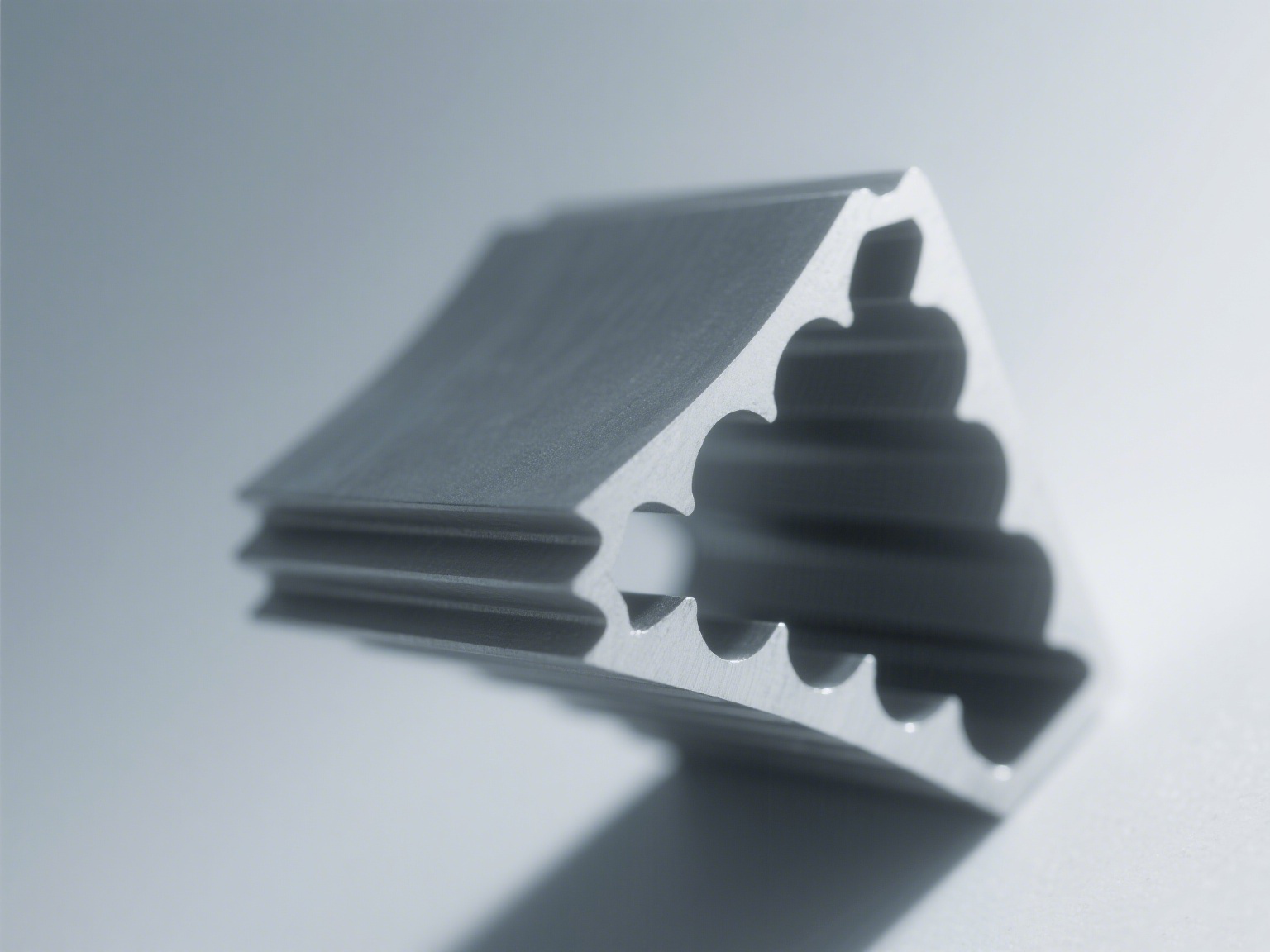

Aluminum stamping transforms raw aluminum into functional parts via a press - and - die system. The process begins with alloy selection—common choices include 5052 (for its formability) and 7075 (for high strength). The aluminum sheet undergoes operations like coining (for surface texture), piercing (to create holes), and flanging (for edge reinforcement). Modern stamping uses servo - driven presses, which offer precise force control for complex shapes, reducing material stress and improving part quality.

2. Standout Features of Stamped Aluminum Parts

| Attribute | Specifications |

| Dimensional Accuracy | Tolerances as tight as ±0.01mm for aerospace - grade components. |

| Form Complexity | Capable of producing multi - feature parts (e.g., slots + bends in one step). |

| Weight Efficiency | Maintains aluminum’s lightweight nature, critical for mobility industries. |

Our parts shine in precision—essential for aerospace fasteners or drone frames. The ability to combine multiple features in one stamping step cuts assembly time for consumer electronics, while weight efficiency benefits automotive and robotics sectors.

3. Advantages of Aluminum Stamping

1. Speed of Production

Progressive dies (with multiple stations) produce complete parts in one pass. For example, an aluminum automotive door hinge can be stamped, bent, and pierced in under 5 seconds per unit.

2. Cost - Effectiveness

High - volume production drives down costs. Stamping 100,000 aluminum heat shields costs 30–40% less than CNC machining, thanks to reduced labor and faster cycle times.

3. Environmental Impact

Low material waste (via optimized nesting) and recyclable aluminum make stamping a sustainable choice, aligning with green manufacturing goals.

4、Where stamped Aluminum Shines

Mobility: Electric scooters and autonomous vehicles use stamped aluminum for frames, reducing weight and boosting energy efficiency.

Areospace: Stamped brackets and panels meet strict weight and strength standards for aircraft.

Consumer goods: From smartwatch frames to kitchen appliance parts, stamping delivers sleek, durable designs.

5、Efficiency in Every Step

• High - Speed Presses: Our equipment runs at 800–1,200 strokes per minute for small parts (e.g., aluminum connectors), ensuring rapid order fulfillment.

• Automated Quality Control: In - line vision systems check dimensions and surface quality, reducing defects and rework.

6、Why Stamping Leads in Aluminum Processing

1. Innovation Enablement

Stamping supports the trend toward lightweight, complex designs (e.g., EV battery enclosures with integrated cooling channels).

2. Reliability

Consistent part quality minimizes assembly issues, a must for industries like medical devices (e.g., stamped aluminum surgical tool components).

3. Future - Proofing

As demand for sustainable, lightweight products grows, stamping aligns with industry shifts—easily adapting to new alloys and design trends.

In the aluminum processing landscape, stamping is more than a manufacturing method—it’s a catalyst for innovation. Our parts prove that when precision, speed, and sustainability matter, stamping is the blueprint for success in crafting the next generation of lightweight, high - performance products.

| Type | Aluminum Stamping | Entrance size | Customized at your needs |