Aluminum Stamping: Shaping the Future of Aluminum Products

Aluminum Stamping: Shaping the Future of Aluminum Products

- Customized at your needs

- Aluminum Stamping

- Customized at your needs

- Informations

- Description

Aluminum Stamping: Shaping the Future of Aluminum Products

Aluminum Stamping: Shaping the Future of Aluminum Products

I. The Art and Science of Aluminum Stamping Process

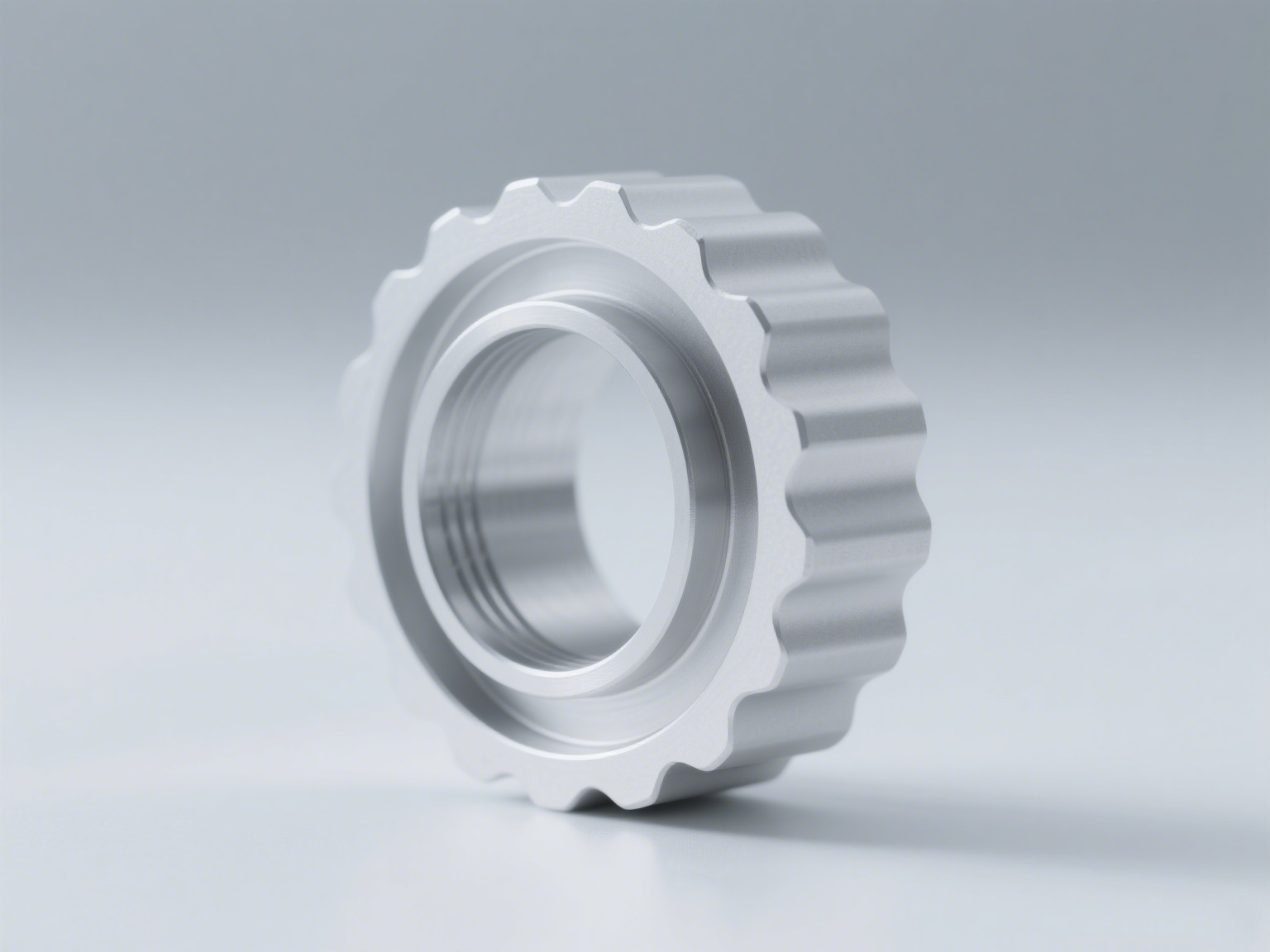

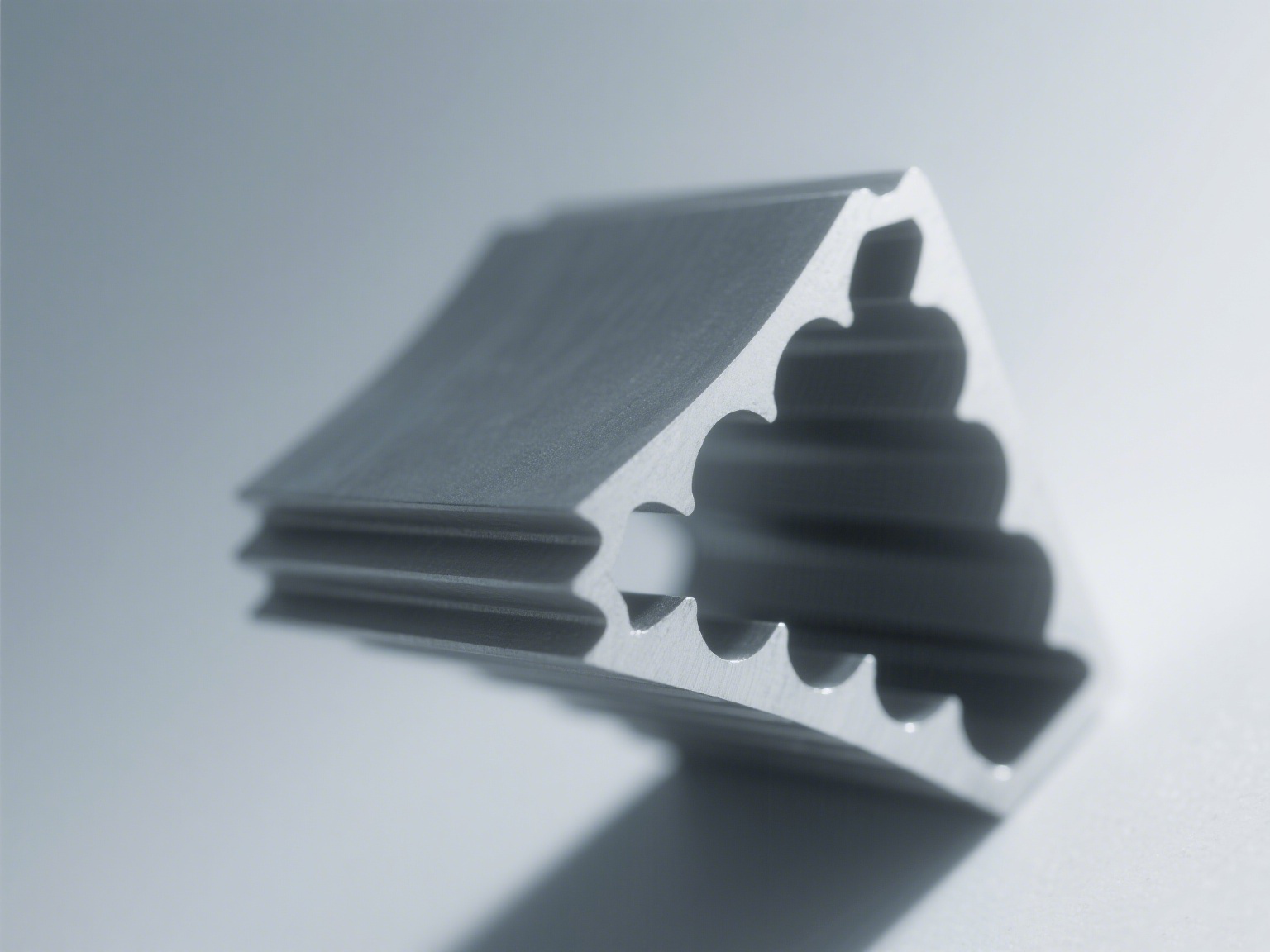

Aluminum stamping is a sophisticated manufacturing process that combines mechanical force and precision tooling. It starts with an aluminum coil or sheet, which is first cleaned and treated to ensure good adhesion and formability. The stamping press, a powerful machine, exerts force on the aluminum through a die set. The die set consists of a punch (the male part) and a die (the female part). When the press activates, the punch pushes the aluminum into the die, causing plastic deformation. This process can include operations like coining (for creating a smooth surface or specific texture), piercing (to make holes), and flanging (to create edges).

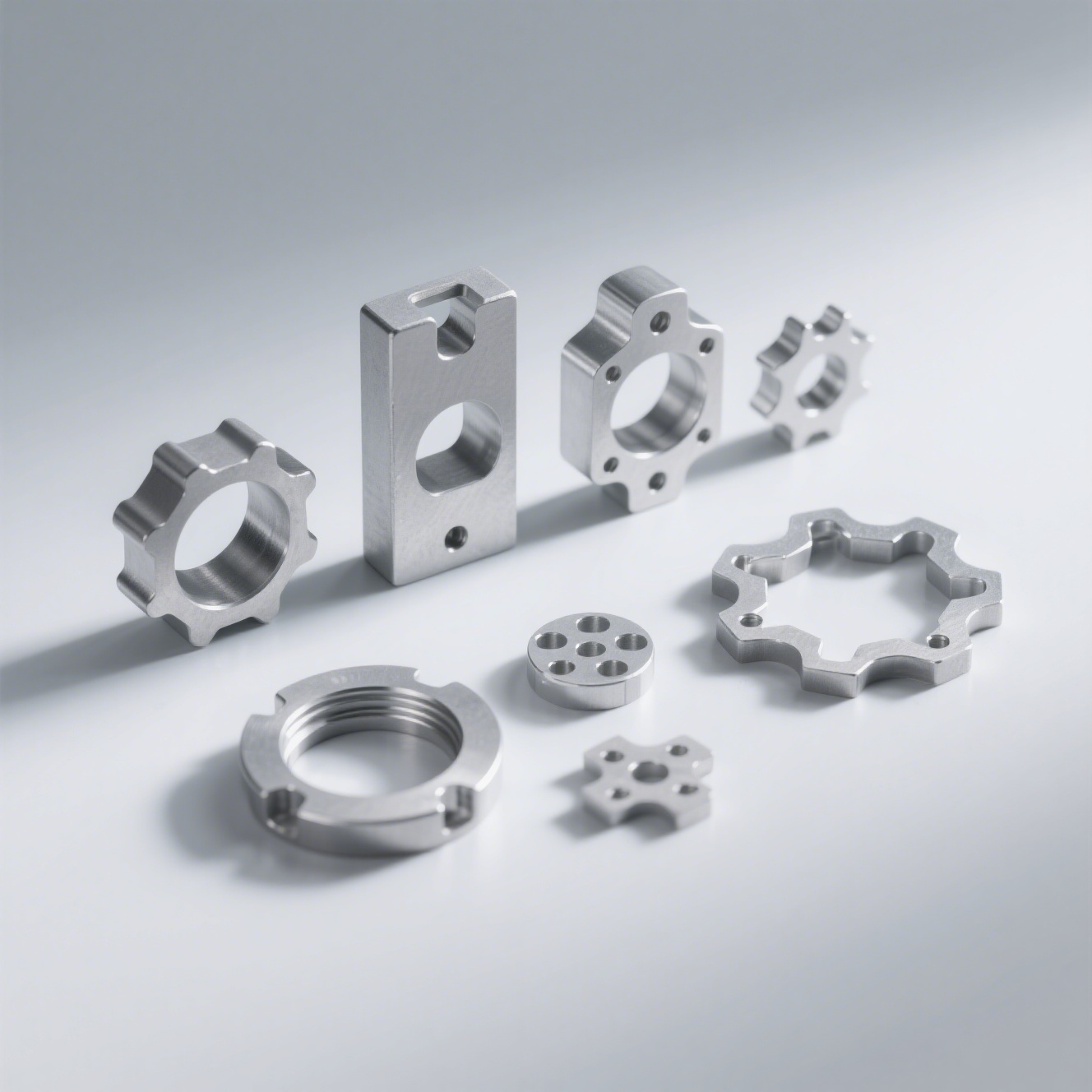

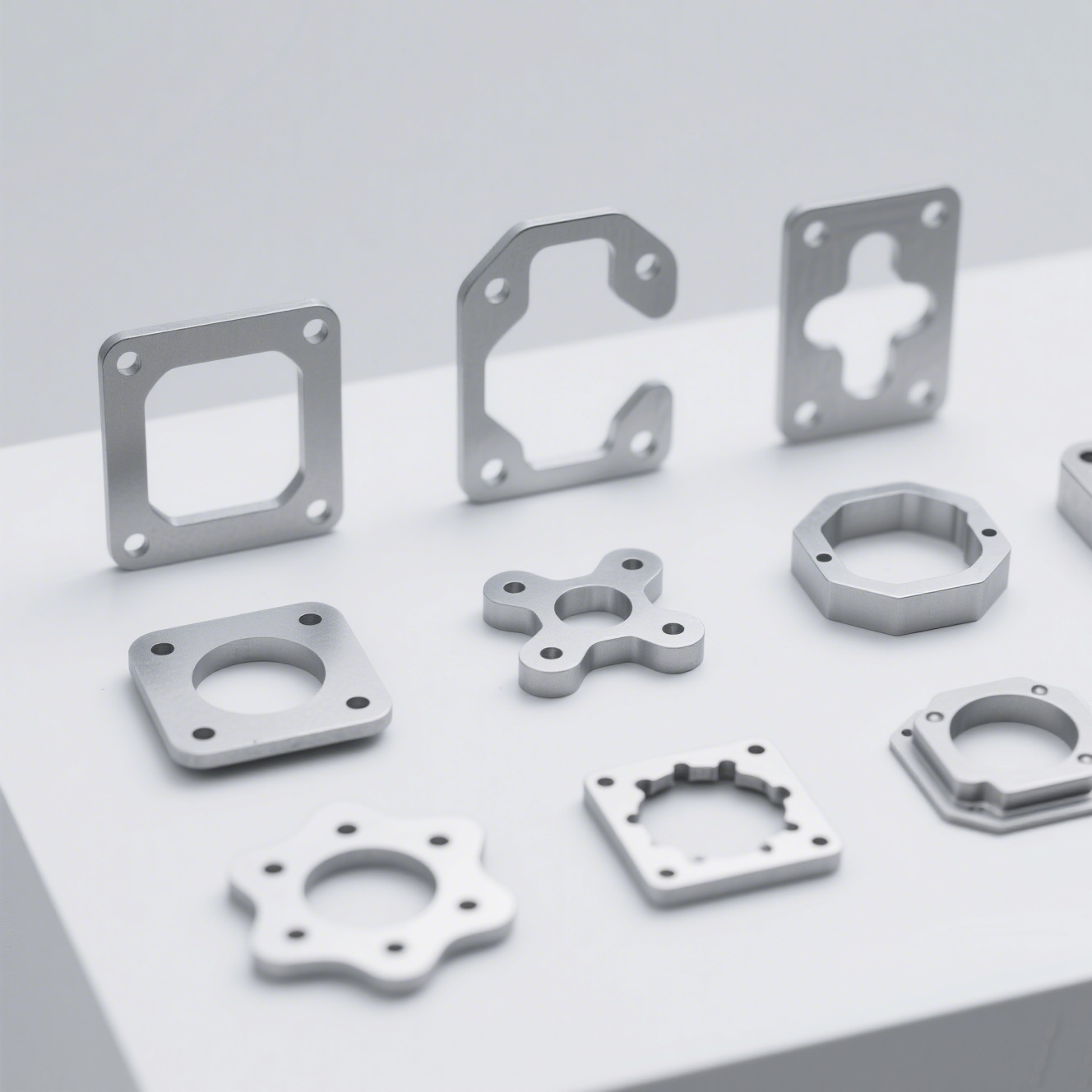

II. Distinctive Features of Stamped Aluminum Parts

| Feature | Description |

| Dimensional Accuracy | Achieves tolerances within ±0.03mm for critical applications, ensuring perfect part - to - part fit. |

| Formability | Can transform aluminum into a variety of shapes, from simple flat parts to complex 3D geometries. |

| Material Integrity | Maintains the inherent properties of aluminum, such as corrosion resistance and thermal conductivity. |

Our stamped aluminum parts are renowned for their dimensional accuracy. In industries like aerospace (where aluminum is also widely used, and similar stamping principles apply), even the slightest deviation can be costly. Our stamping process, with high - precision dies and advanced press control, ensures that each part meets the strictest dimensional requirements. The formability of aluminum in our stamping process is also a major advantage. We can create parts with deep draws, sharp bends, and intricate details, which is essential for products like aluminum enclosures for medical devices. And throughout the stamping process, the material integrity of aluminum is preserved, so our parts retain their excellent corrosion resistance, making them suitable for outdoor and harsh - environment applications.

III. The Edge: Advantages of Aluminum Stamping

1. Time - Saving in Production

The stamping process is a one - step or multi - step (in a progressive die) operation that can quickly produce parts. For example, in the production of aluminum connectors (similar to the more complex stamped parts in the image), a progressive die can perform multiple operations like cutting, bending, and forming in a single pass, reducing production time significantly.

2. Cost - Efficiency in the Long Run

Although the initial investment in die design and manufacturing can be relatively high, the cost per unit drops drastically for large production volumes. This is because the stamping process is highly automated, requiring minimal labor for production. For mass - produced aluminum parts like those used in consumer appliances, stamping proves to be a cost - effective solution.

3. Enhanced Mechanical Properties

The cold working during stamping improves the strength of aluminum. The work hardening effect makes our stamped parts more resistant to deformation under load, which is beneficial for structural components in various industries.

IV. Where Our Stamped Parts Shine: Application Areas

1. Renewable Energy Sector

In solar panel frames and wind turbine components, aluminum stamping is used to create lightweight yet strong parts. The ability to produce large - scale, consistent parts is crucial for the renewable energy industry, where cost and reliability are key.

2. Medical Equipment

Aluminum stamping is used to make parts for medical devices such as surgical instruments (handles and casings) and diagnostic equipment enclosures. The precision and biocompatibility (when appropriate surface treatments are applied) of our stamped aluminum parts make them ideal for this sensitive industry.

3. Consumer Goods

From aluminum cookware components (like handles and lids) to the frames of bicycles and sports equipment, our stamped parts add value through their precision and durability.

V. Speed and Efficiency: The Stamping Advantage

1. Rapid Cycle Times

Our stamping presses can achieve cycle times as low as a few seconds per part for simple designs. For high - volume production of aluminum parts like washers or small brackets, this rapid cycle time means we can meet large - scale demand quickly.

2. Efficient Material Handling

The use of automated feed systems in our stamping process ensures that the aluminum sheet or coil is handled efficiently. There is minimal waste in material feeding, and the entire process from raw material to finished part is optimized for speed and efficiency. This is especially important for large - scale production runs, where any inefficiency can lead to increased costs.

VI. The Rationale for Stamping in Aluminum Processing

1. Adaptability to Design Changes

While die changes can be costly, modern stamping technology allows for relatively quick and cost - effective die modifications. This means that as product designs evolve in the aluminum processing industry, stamping can adapt to new shapes and requirements with less disruption compared to some other manufacturing processes.

2. Quality Assurance

Stamping provides a high level of quality control. The use of precision dies and automated processes ensures that each part meets the same quality standards. In industries where product safety and reliability are paramount, like automotive and medical, this quality assurance is invaluable.

3. Sustainability

The high material utilization in stamping (due to optimized part nesting on the aluminum sheet) reduces waste. Also, aluminum is a highly recyclable material, and the stamping process does not significantly degrade its recyclability. This makes stamping an environmentally friendly choice in the aluminum processing industry.

In the dynamic world of aluminum product manufacturing, our aluminum stamping parts stand out as a perfect blend of precision, efficiency, and quality. They are the building blocks for innovativ

| Type | Aluminum Stamping | Entrance size | Customized at your needs |