Aluminum Stamping Parts: Powering Innovation in Manufacturing

Aluminum Stamping Parts: Powering Innovation in Manufacturing

- Customized at your needs

- Aluminum Stamping

- Customized at your needs

- Informations

- Description

Aluminum Stamping Parts: Powering Innovation in Manufacturing

Aluminum Stamping Parts: Powering Innovation in Manufacturing

1. Aluminum Stamping Process Unveiled

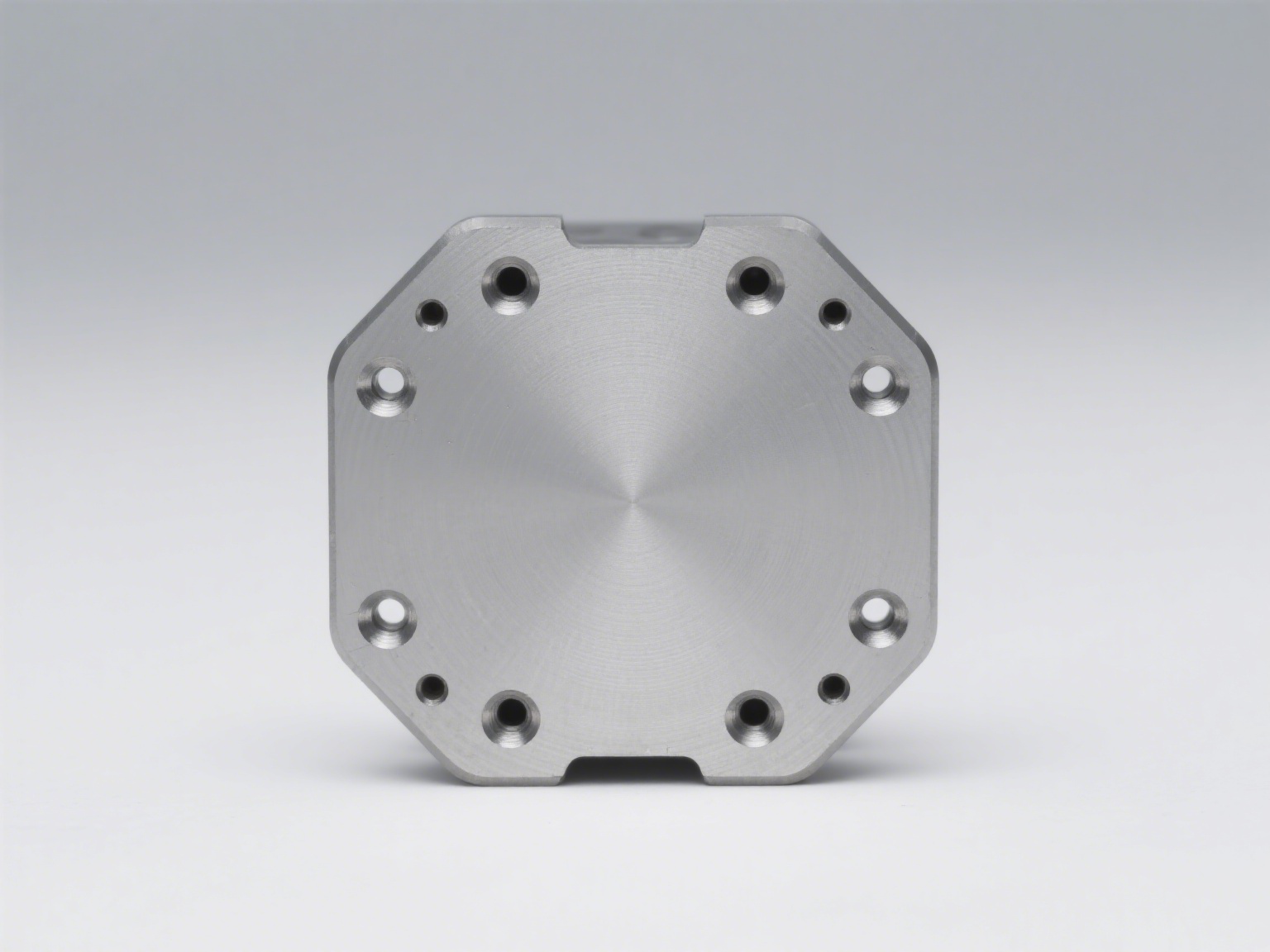

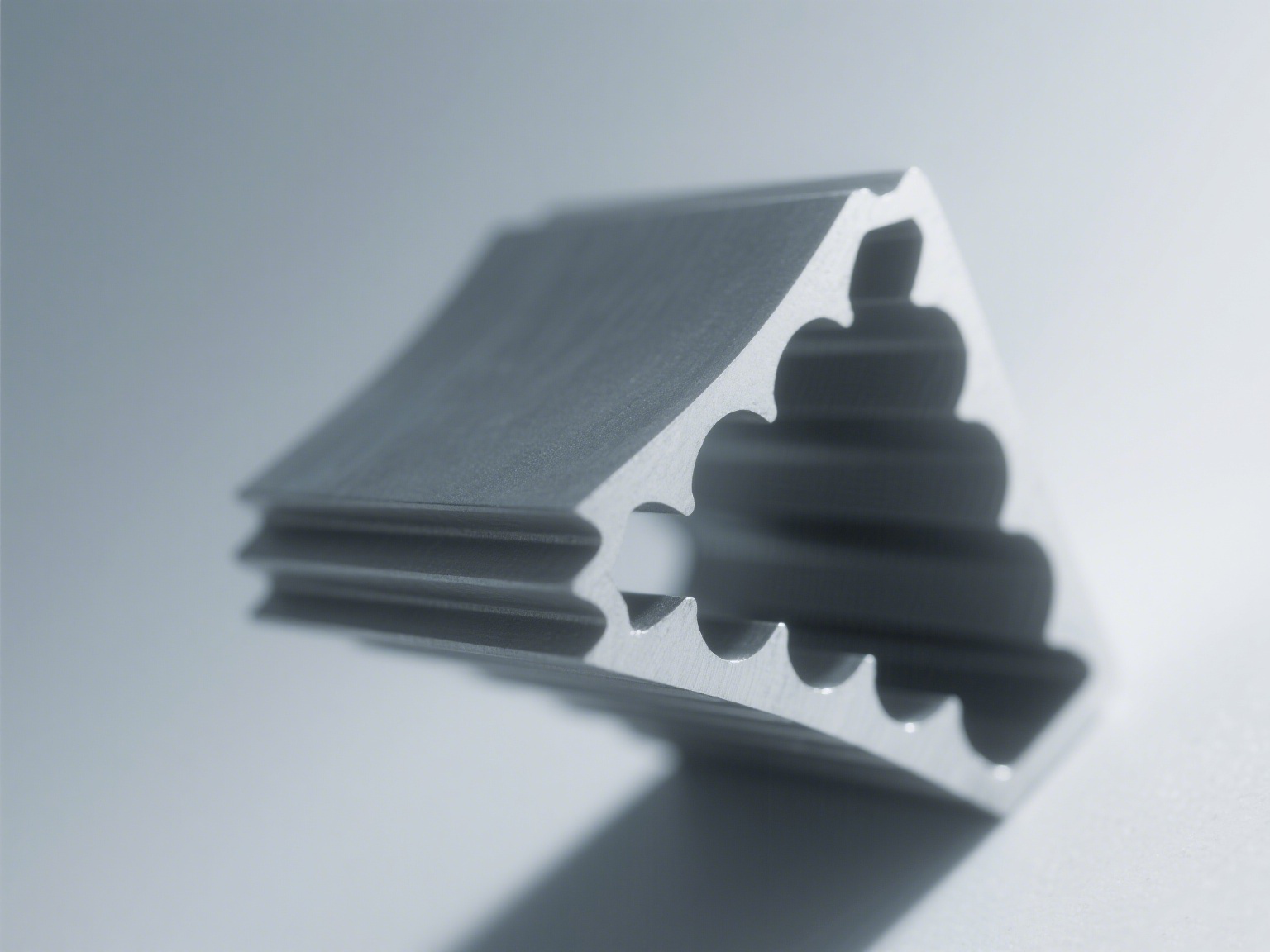

Aluminum stamping is a transformative manufacturing process. It starts with flat aluminum sheets, which are fed into precision - engineered dies within a stamping press. The press applies force, using a combination of blanking (to cut the initial shape), bending (for angular forms), and deep - drawing (to create hollow structures). High - grade aluminum alloys, like 6063 (ideal for extrusions and stampings) or 3003 (for its corrosion resistance), are commonly used. The process leverages automated feed systems and computer - controlled presses to ensure accuracy, even for complex geometries.

2. Key Features of Our Stamped Aluminum Components

| Feature | In - Depth Details |

| Precision | Achieves tolerances of ±0.02mm, ensuring seamless integration into assemblies. |

| Surface quality | Smooth, burr - free finishes, reducing post - processing needs. |

| Material Integrity | Maintains aluminum’s natural properties (lightweight, corrosion - resistant). |

Our parts excel in precision—critical for automotive engine components or aerospace brackets. The surface quality eliminates the need for extensive polishing in consumer electronics, while the retained material integrity ensures durability in outdoor applications like solar panel frames.

3. Advantages of Aluminum Stamping

Cost - Efficiency

For large production runs, stamping reduces per - unit costs. Dies, once created, enable rapid part production. For example, stamping 10,000 aluminum brackets costs far less in labor and material waste compared to manual fabrication.

Strength & Lightweight

Stamping work - hardens aluminum, enhancing strength without adding weight. This is vital for electric vehicle (EV) parts, where reducing weight boosts battery range.

Material Utilization

Computer - optimized nesting of parts on aluminum sheets minimizes scrap, cutting raw material costs and environmental impact.

4、Application Range

Automotive: From EV battery trays to interior trim, stamping provides lightweight, strong components.

Electronics: Precision - stamped heat sinks and phone chassis leverage aluminum’s thermal conductivity and aesthetics.

Renewable Energy: Solar panel mounts and wind turbine connectors rely on stamping for consistency and durability.

5、Speed & Efficiency Highlights

Rapid Cycle Times: Our presses achieve 500–1,000 parts per hour for simple designs (e.g., aluminum washers), thanks to automated feeding and high - speed press mechanisms.

Streamlined Workflow: Integration with CAD/CAM systems allows seamless design - to - production transitions, cutting lead times for custom parts.

6、Why Choose Stamping in Aluminum Processing?

Versatility

Stamping handles aluminum thicknesses from 0.1mm (electronics) to 10mm (industrial brackets), adapting to diverse needs.

Consistency

Automated processes ensure every part matches design specs—critical for industries like medical devices, where component uniformity is non - negotiable.

Scalability

Perfect for both 100 - unit prototypes and 100,000 - unit mass production. Dies can be modified cost - effectively for design iterations.

In the aluminum processing industry, stamping stands out as a blend of precision, efficiency, and adaptability. Our parts empower innovation across sectors, proving that when it comes to aluminum fabrication, stamping is the smart choice for performance - driven products.

| Type | Aluminum Stamping | Entrance size | Customized at your needs |