Excellence in Aluminum Stamping: A Cut Above the Rest

Excellence in Aluminum Stamping: A Cut Above the Rest

- Customized at your needs

- Aluminum Stamping

- Customized at your needs

- Informations

- Description

Excellence in Aluminum Stamping: A Cut Above the Rest

Excellence in Aluminum Stamping: A Cut Above the Rest

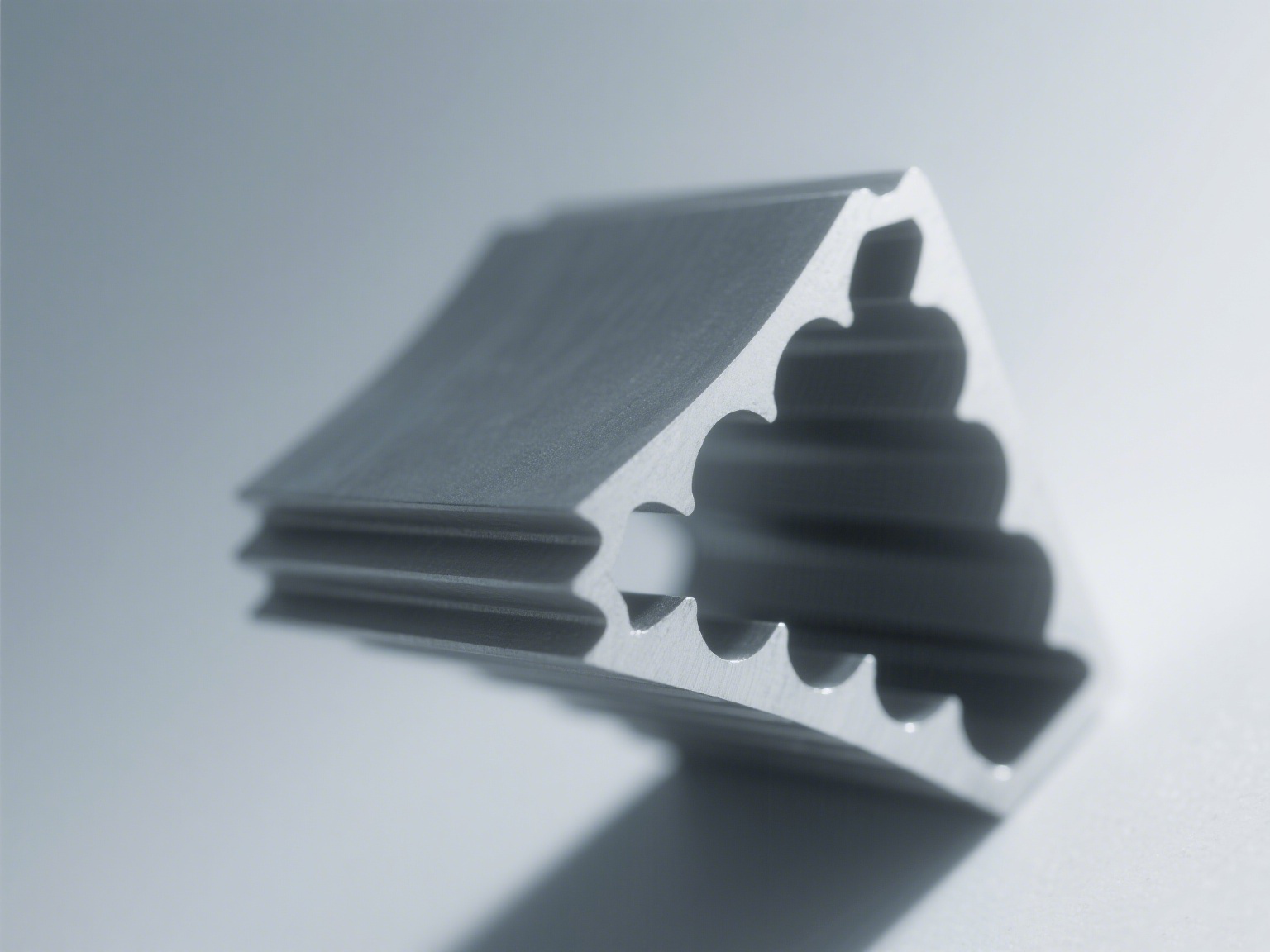

I. Unveiling the Aluminum Stamping Process

Aluminum stamping is a manufacturing marvel that starts with raw aluminum in the form of sheets or coils. The first step is often blanking, where a large aluminum sheet is cut into smaller, more manageable blanks using a blanking die. These blanks then enter the stamping press, where a combination of punches and dies shapes them. The process can involve multiple stages in a progressive stamping operation, where each stage performs a specific operation like bending, forming, or punching. Lubricants are sometimes used to reduce friction between the aluminum and the die, ensuring smooth deformation and prolonging die life.

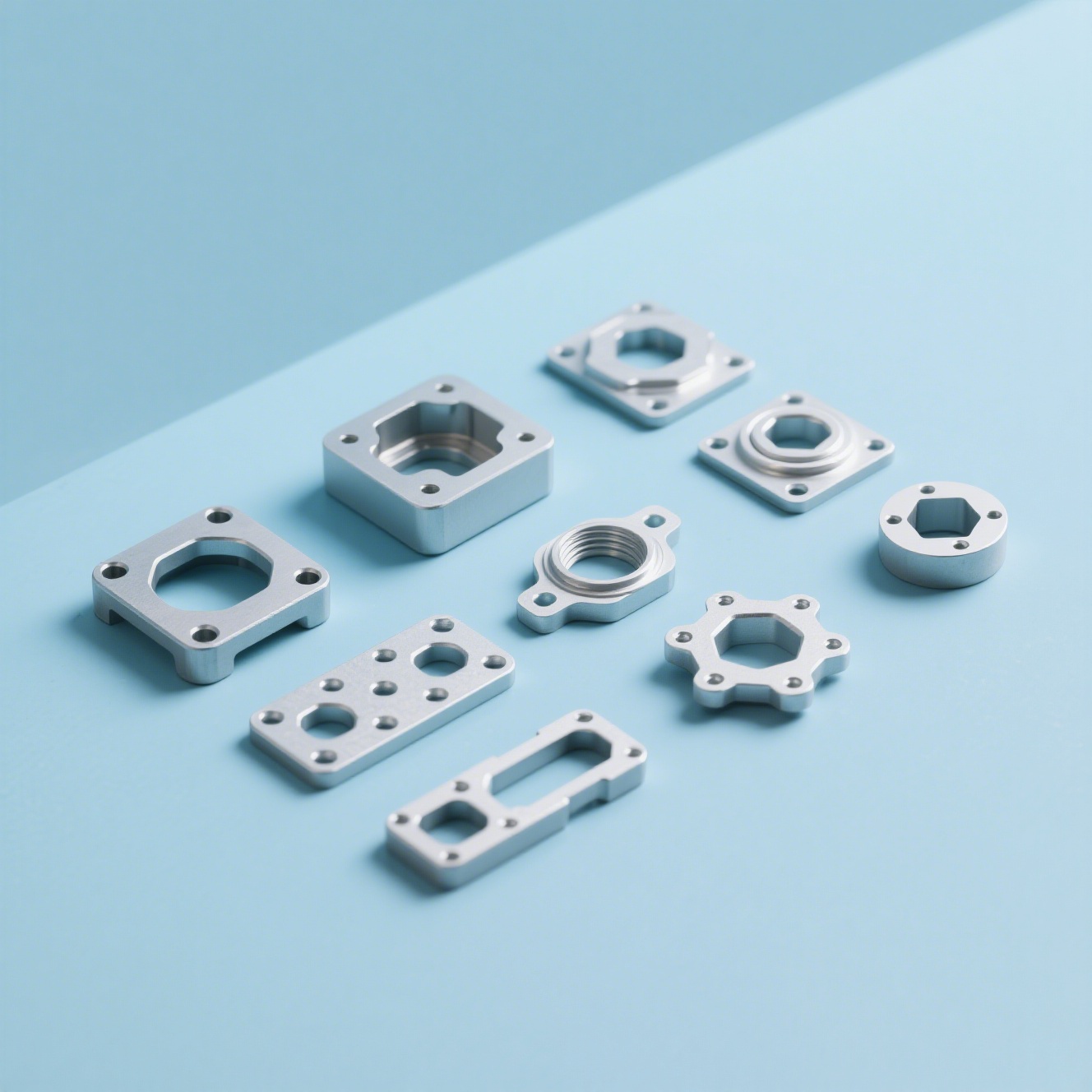

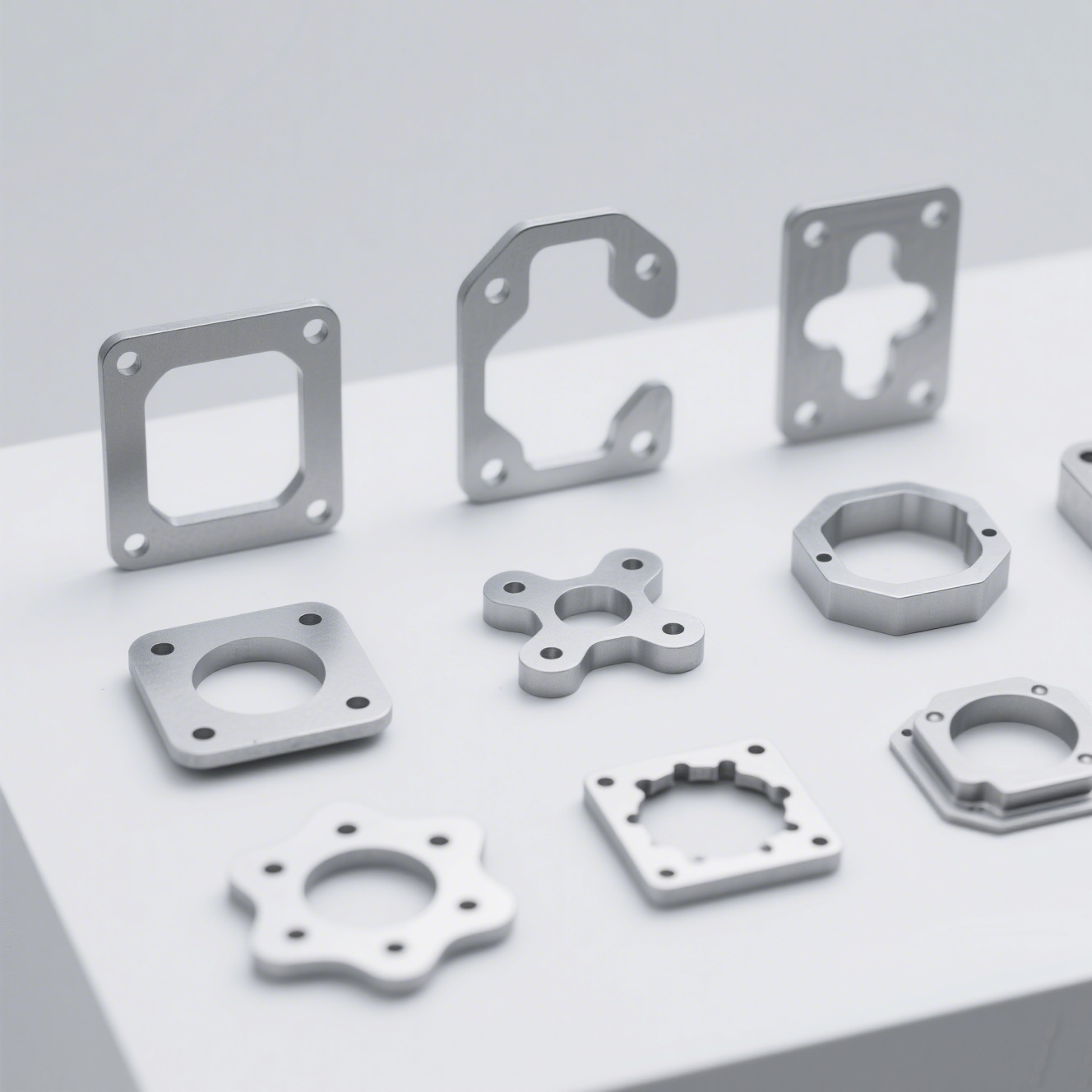

II. Standout Features of Our Stamped Aluminum Components

| Feature | In - Depth Details |

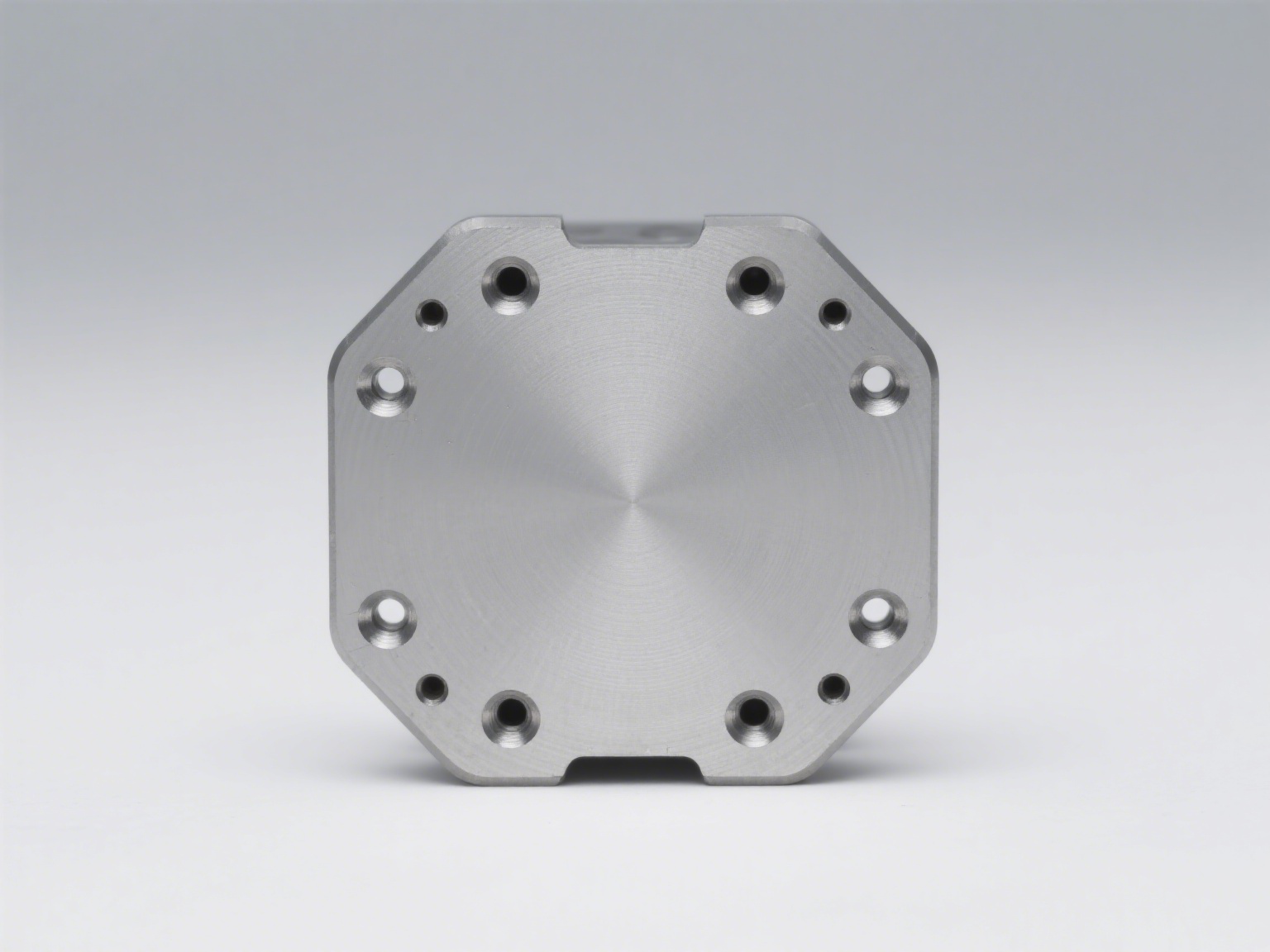

| Precision Engineering | Our parts have tolerances of ±0.02mm for critical dimensions, ensuring seamless integration into complex assemblies. |

| Aesthetic Appeal | The stamping process can create parts with a polished, professional look, enhancing the overall product design. |

| Customizability | We can produce stamped parts in a wide range of shapes and sizes, from tiny aluminum contacts to large industrial brackets. |

Our stamped aluminum components are a testament to precision engineering. In the electronics industry, where miniaturization is key, our ability to produce parts with extremely tight tolerances allows for the creation of smaller, more powerful devices. The aesthetic appeal of our parts is not to be overlooked. For consumer products like high - end audio equipment, the smooth, precise lines of our stamped aluminum parts add to the product's visual allure. And when it comes to customizability, we can work with clients to create unique stamped parts that meet their specific design requirements, whether it's a one - of - a - kind prototype or a mass - produced component.

III. The Competitive Advantages of Aluminum Stamping

Mass Production Prowess

Stamping is ideal for mass production. Once the dies are set, we can produce thousands of identical parts per day. For example, in the production of aluminum buttons for automotive interiors, our stamping process can churn out consistent, high - quality parts at a rapid rate, meeting the high - volume demands of the automotive industry.

Cost - Efficiency

The cost per part decreases as production volume increases. The initial investment in die - making is offset by the low variable costs of production. This makes aluminum stamping an attractive option for businesses looking to balance quality and cost in the aluminum processing industry.

Strength and Lightweight

Stamped aluminum parts offer an excellent strength - to - weight ratio. This is crucial for industries like aerospace (where aluminum is a staple material, and stamping techniques are similar) and automotive, where reducing weight without sacrificing strength can lead to improved performance and fuel efficiency.

IV. Diverse Applications of Stamped Aluminum Parts

Aerospace and Aviation

Stamped aluminum parts are used in aircraft interiors (such as seat frames and paneling) and external components like wing flaps and fuselage parts. The precision and lightweight nature of these parts are essential for aircraft design.

Telecommunications

In the telecommunications industry, our stamped parts are used to create antenna components, housing for communication devices, and connectors. The ability to produce high - precision parts quickly is vital in this fast - paced industry.

Construction

For the construction industry, we produce aluminum stamping parts like window frames, door hinges, and structural brackets. These parts need to be durable and precise to ensure the safety and functionality of buildings.

V. Speed and Efficiency in Stamping Operations

High - Throughput Stamping

Our state - of - the - art stamping presses can achieve high throughput rates. For simple aluminum parts like washers or clips, we can produce hundreds per minute. This high - speed production is made possible by advanced automation and optimized die designs.

Streamlined Workflow

From the initial design phase to the final inspection of stamped parts, our workflow is streamlined. We use computer - aided manufacturing (CAM) software to optimize the stamping process, reducing setup times and ensuring that each part is produced efficiently. This efficiency not only saves time but also reduces costs in the long run.

VI. The Case for Stamping in Aluminum Processing

Consistency in Quality

Stamping ensures that every part is almost identical. This is crucial for industries where product uniformity is required, such as the automotive industry, where thousands of the same part need to fit and function perfectly.

Technological Advancements

The aluminum stamping industry is constantly evolving, with new technologies like servo - driven stamping presses and 3D - printed dies emerging. These advancements allow for greater precision, faster production, and more complex part designs, keeping stamping at the forefront of aluminum processing methods.

Material Efficiency

As mentioned earlier, stamping maximizes material utilization through optimized part nesting. This not only reduces waste but also makes the most of the valuable aluminum resource, contributing to the sustainability of the aluminum processing industry.

In conclusion, our aluminum stamping parts are a symbol of excellence in the aluminum processing industry. With their precision, versatility, and efficiency, they are the go - to choice for a wide range of applications, driving innovation and quality in manufacturing.

| Type | Aluminum Stamping | Entrance size | Customized at your needs |