Aluminum Stamping: Precision, Performance, and Possibilities

Aluminum Stamping: Precision, Performance, and Possibilities

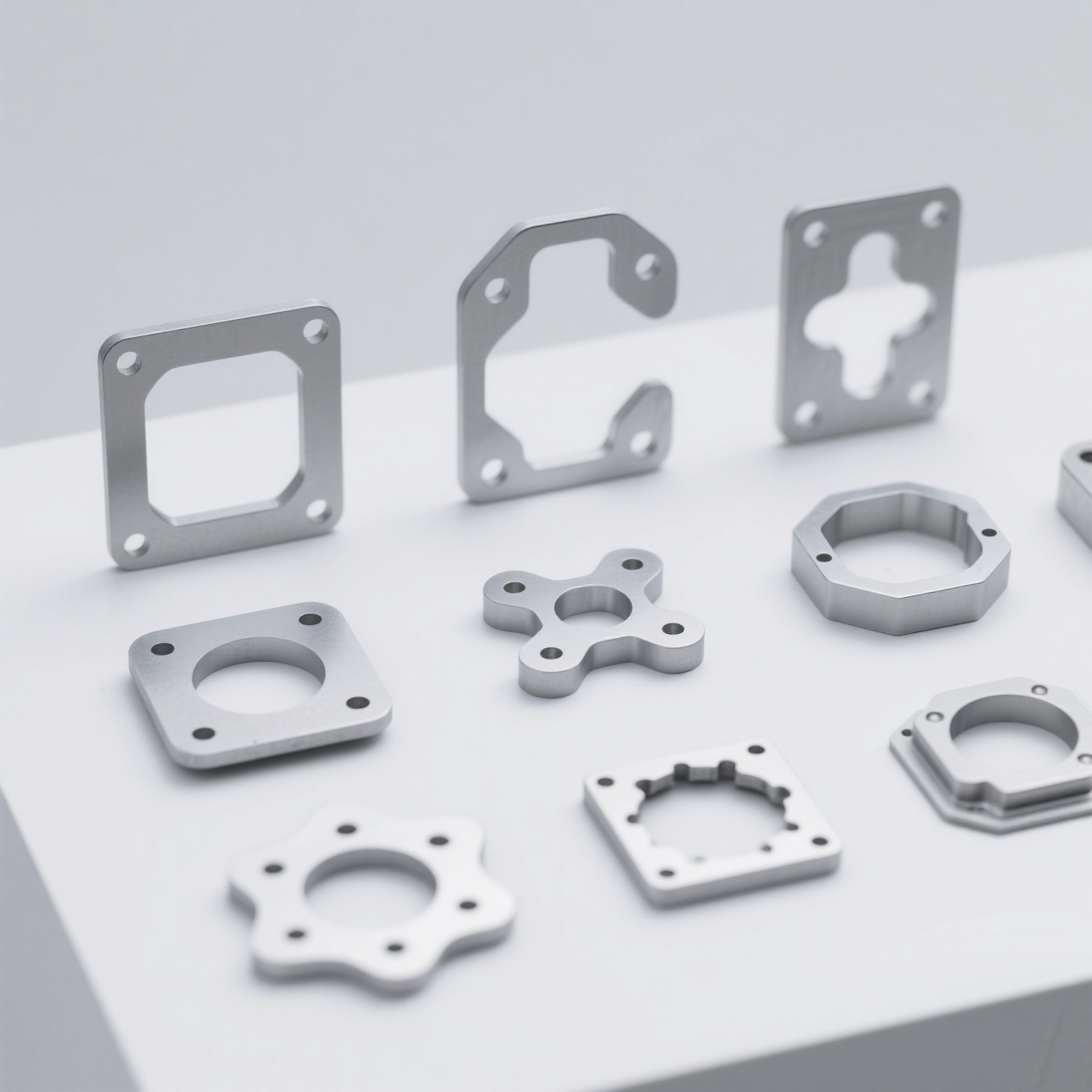

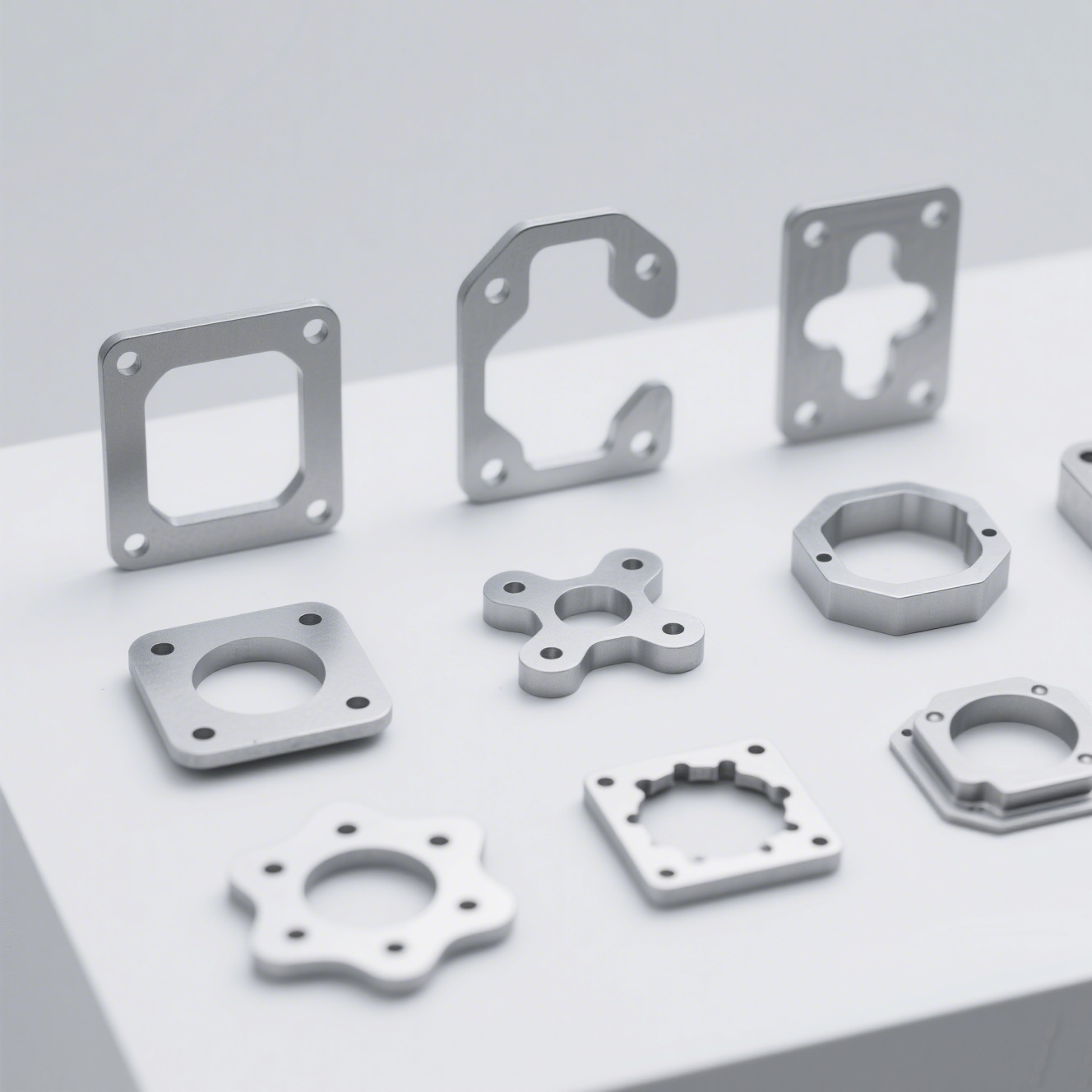

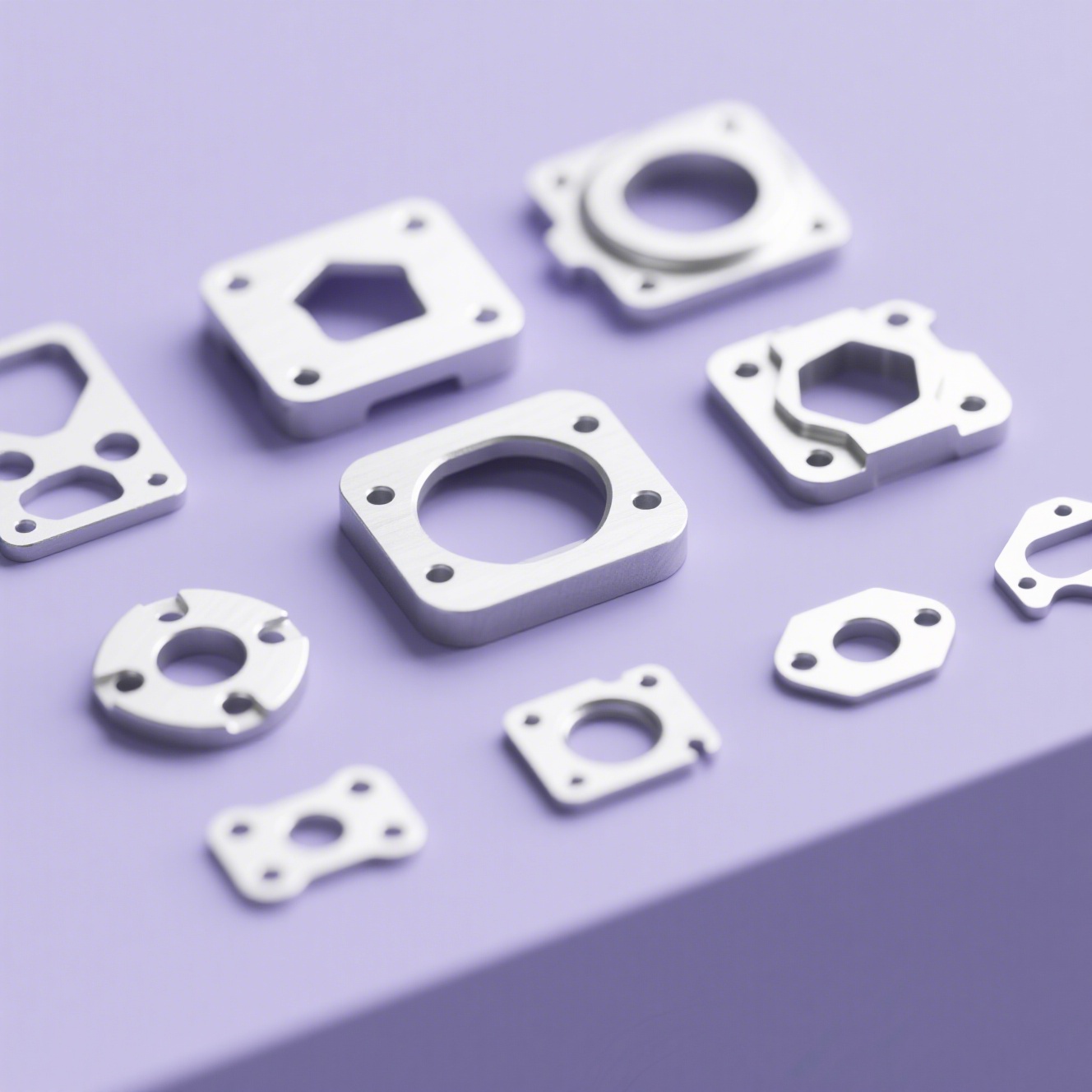

- Customized at your needs

- Aluminum Stamping

- Customized at your needs

- Informations

- Description

Aluminum Stamping: Precision, Performance, and Possibilities

Aluminum Stamping: Precision, Performance, and Possibilities

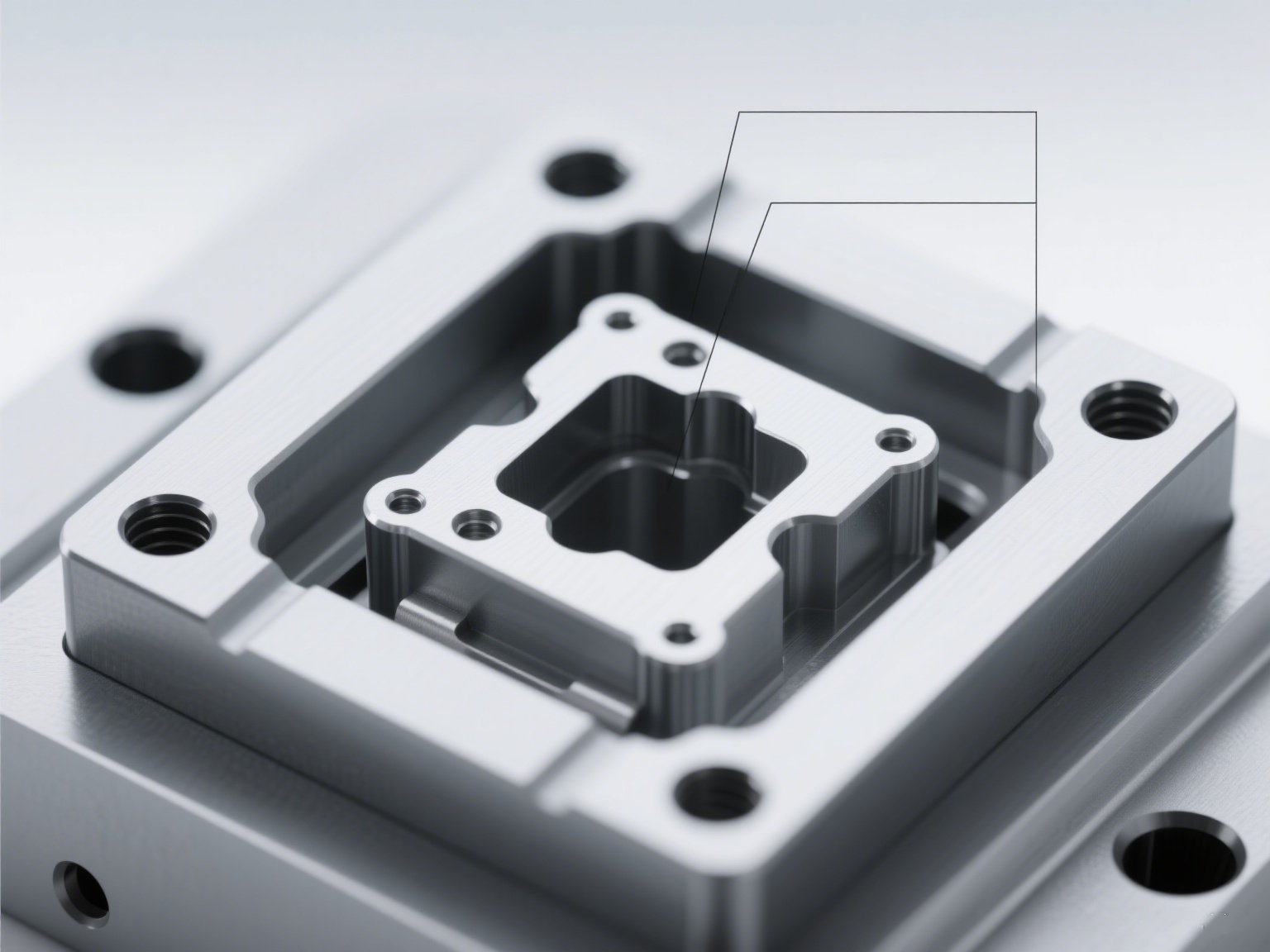

I. The Intricacies of Aluminum Stamping Process

Aluminum stamping is a manufacturing process that begins with the selection of appropriate aluminum alloys based on the application requirements. The process involves placing an aluminum sheet between a punch and a die. The punch, powered by a stamping press, descends and forces the aluminum into the die cavity, causing it to deform. This can be a single - stage process for simple shapes or a multi - stage process for more complex parts. In multi - stage stamping, the aluminum part moves from one die station to another, with each station performing a specific operation like cutting, bending, or embossing.

II. Features That Define Our Aluminum Stamping Parts

| Feature | Specifics |

| Precision Machining | Our parts have tolerances as low as ±0.01mm for high - precision applications, ensuring accurate fit and function. |

| Material Strength | The stamping process enhances the strength of aluminum, making our parts suitable for load - bearing applications. |

| Design Flexibility | We can produce parts with unique shapes, including undercuts and complex curves, to meet diverse design needs. |

Our aluminum stamping parts are precision - machined to the highest standards. In the medical device industry, where precision is life - critical, our parts with tight tolerances ensure the proper functioning of devices like insulin pumps and surgical robots. The enhanced material strength of our stamped parts makes them ideal for industrial applications, such as aluminum brackets for heavy machinery. And with design flexibility, we can bring our clients' most innovative ideas to life, whether it's a futuristic consumer product or a cutting - edge industrial component.

III. The Advantages of Aluminum Stamping

1. Economies of Scale

For large production runs, the cost per unit of aluminum stamping parts is very low. The fixed cost of die production is spread over a large number of parts, making it an economical choice for mass - produced items like aluminum cans (although can production has its own specific stamping - like processes) and automotive parts.

2. Speed of Production

Stamping is a fast process. A single stamping press can produce hundreds Aluminum parts at the same time.

| Type | Aluminum Stamping | Entrance size | Customized at your needs |