Aluminum Stamping Parts: Precision in Every Punch

Aluminum Stamping Parts: Precision in Every Punch

- Customized at your needs

- Aluminum Stamping

- Customized at your needs

- Informations

- Description

Aluminum Stamping Parts: Precision in Every Punch

Aluminum Stamping Parts: Precision in Every Punch

I. Introduction to Aluminum Stamping Process

Aluminum stamping is a manufacturing process where flat aluminum sheets are transformed into desired shapes using a stamping press and precision - made dies. The process begins with the selection of high - quality aluminum alloys, such as 6061 or 5052, which offer good formability and strength. The aluminum sheet is then fed into a stamping machine, where a punch and die set work in tandem. The punch applies force to the aluminum, causing it to deform and take on the shape of the die cavity. This can involve a series of operations like blanking (to cut out the initial shape), bending (to create angles and curves), and deep drawing (for creating deep, hollow shapes).

II. Features of Our Aluminum Stamping Parts

| Feature | Details |

| Precision | Tight tolerances, often as low as ±0.05mm, ensuring parts fit perfectly in assemblies. |

| Surface Finish | Smooth and consistent, reducing the need for additional post - processing in many cases. |

| Complex Geometries | Capable of producing intricate shapes with multiple bends, holes, and protrusions. |

Our aluminum stamping parts boast exceptional precision. Thanks to advanced die - making technology and high - precision stamping presses, we can achieve tight tolerances that are crucial for applications in electronics and automotive industries. The surface finish of our stamped parts is also a standout feature. The stamping process, when optimized, can produce parts with a smooth surface that enhances both the aesthetic and functional aspects, especially in consumer products. Moreover, the ability to create complex geometries means that we can meet the diverse design requirements of modern products, from the sleek shapes of consumer electronics to the robust structures in industrial equipment.

III. Advantages of Aluminum Stamping

1. Cost - Effectiveness for Mass Production

Once the dies are created, the cost per part decreases significantly for large production runs. The stamping process is highly automated, reducing labor costs. For example, in the production of aluminum brackets for automotive interiors, stamping can produce hundreds of parts per hour with minimal human intervention.

2. Material Utilization

The stamping process is designed to maximize material usage. The layout of parts on the aluminum sheet is optimized using computer - aided design (CAD) software, minimizing scrap. This is not only environmentally friendly but also cost - effective, as less raw material is wasted.

3. Strength and Durability

The stamping process can work - harden the aluminum, enhancing its strength. This is beneficial for parts that need to withstand mechanical stress, such as aluminum chassis components in electronics. The formed parts have a uniform structure, which contributes to their overall durability.

IV. Application Range

1. Automotive Industry

Aluminum stamping parts are widely used in cars, from body panels (such as fenders and hoods in some lightweight designs) to interior components like dashboard frames and seat brackets. The lightweight nature of aluminum, combined with the strength achieved through stamping, helps in improving fuel efficiency and overall vehicle performance.

2. Electronics Sector

In consumer electronics like smartphones and laptops, aluminum stamping is used to create battery enclosures, heat sinks, and frame components. The precision and thin - wall capabilities of stamping are ideal for these compact and high - performance devices.

3. Industrial Equipment

For industrial machinery, aluminum stamping produces parts such as brackets, mounts, and covers. These parts need to be durable and precise to ensure the proper functioning of the equipment.

V. Processing Speed and Efficiency

1. High - Speed Stamping

Our stamping presses are capable of high - speed operations. For simple parts, we can achieve production rates of up to 1000 parts per hour. This is due to the automated feeding systems and quick - acting punch - die mechanisms.

2. Efficient Production Flow

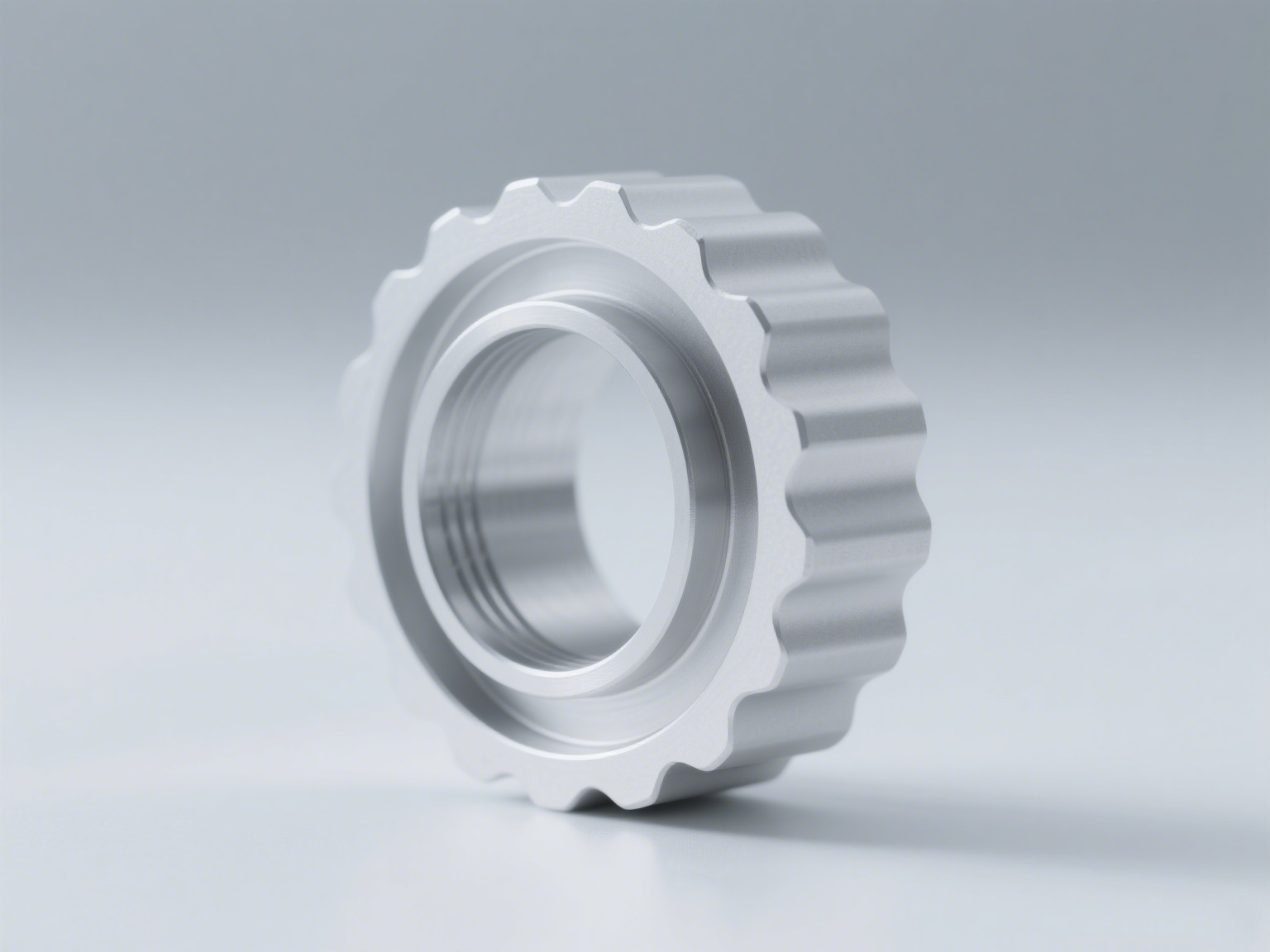

The stamping process can be integrated into a continuous production line. From raw material input to finished part output, the workflow is streamlined. For example, in the production of aluminum rings (similar to those in the image), we can have a seamless process that includes stamping, deburring, and quality inspection, all in one flow, reducing production time and increasing efficiency.

VI. Why Choose Stamping in Aluminum Processing Industry

1. Versatility

Stamping can handle a wide range of aluminum thicknesses, from thin foils (as thin as 0.1mm) for electronics to thicker sheets (up to 10mm or more) for industrial applications. This versatility makes it suitable for almost any aluminum product design.

2. Consistency

Unlike some manual or less - automated processes, stamping ensures that each part is almost identical. This is crucial for mass - produced products where interchangeability and uniform quality are required. For example, in the automotive industry, where thousands of the same part are needed, stamping guarantees that every bracket or panel meets the same specifications.

3. Scalability

As mentioned before, stamping is highly scalable. Whether a company needs 100 prototype parts or 100,000 mass - produced parts, the stamping process can be adjusted accordingly. The initial cost of die creation is offset by the low cost per part in large production, making it a viable option for both small - scale and large - scale production in the aluminum processing industry.

In conclusion, our aluminum stamping parts represent the pinnacle of precision, efficiency, and quality in the aluminum processing industry. Whether you are in the automotive, electronics, or industrial sector, our stamped parts can meet your needs and help you create better products.

| Type | Aluminum Stamping | Entrance size | Customized at your needs |