Anodic Oxidation of Aluminum Parts

Anodic Oxidation of Aluminum Parts

- Customized

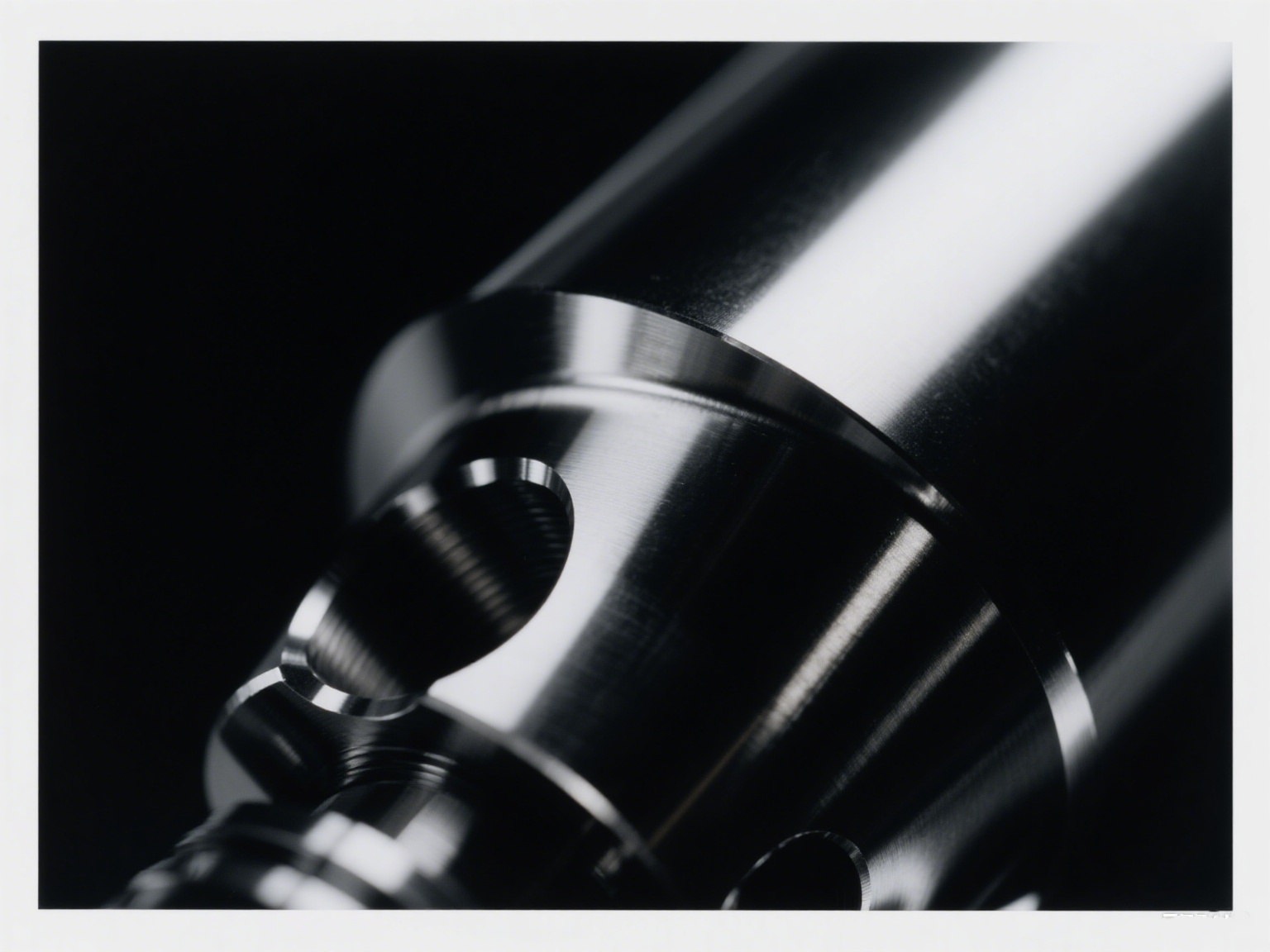

- Aluminum parts anodic oxidation

- Customized

- Informations

- Description

Anodic Oxidation of Aluminum Parts

Anodic Oxidation of Aluminum Parts: Innovating Manufacturing for Modern Industries

The anodic oxidation process revolutionizes aluminum part production by addressing key industrial challenges. Its cost-effectiveness—offering long-term durability at a fraction of stainless steel costs—drives adoption in mass manufacturing. The oxide layer’s dielectric strength (up to 100 V/μm) makes it invaluable for electrical enclosures, while its non-conductive properties protect sensitive electronics.

Step-by-Step Machining: After material selection (6061 or 7075 aluminum alloys are preferred), parts undergo mechanical pre-finishing (polishing or blasting) to achieve the desired surface texture. Anodizing in oxalic acid baths yields a thicker, more decorative layer, ideal for architectural applications. Post-treatment with nickel acetate sealing ensures compliance with ISO 7599 for food-contact surfaces, seen in beverage can manufacturing.

Industry-Specific Use Cases: In renewable energy, anodized aluminum frames for solar panels withstand outdoor elements, extending service life. The defense sector employs it for lightweight armor components, balancing protection and mobility. Electronics manufacturers use it for heat dissipation in LED lighting, where the oxide layer’s thermal conductivity efficiently transfers heat.

Industry Applications of Anodized Aluminum Parts

Industry Sector | Application Scenarios | Material Requirements | Regulatory Compliance |

Automotive | Engine components, wheel rims, exterior trims | 6061/7075 aluminum alloys; salt spray resistance >500 hours | SAE J2334 (corrosion test); ISO 16750 (thermal cycling) |

Aerospace | Aircraft structural parts, fuel system components | 2024-T3/7075-T6 alloys; weight reduction up to 30% | FAA AC 20-135A (aerospace materials); MIL-A-8625F (anodizing standards) |

Electronics | Smartphone casings, heat sinks, PCB enclosures | Surface roughness: Ra <0.8 μm; dielectric strength >80 V/μm | RoHS 2.0 (2011/65/EU); IEC 60684 (insulation requirements) |

Architecture | Curtain walls, facade systems, decorative panels | Anodizing class II (AAMA 611); color fastness to weathering >8 级 (ISO 105-B04) | ASTM B117 (5000-hour salt spray test); EN 12373-1 (architectural standards) |

Medical Devices | Surgical instrument casings, diagnostic equipment housings | Biocompatibility: ISO 10993-5; non-toxic sealing (nickel-free) | FDA 21 CFR Part 880; CE Mark (MDR 2017/745) |

| Type | Aluminum parts anodic oxidation | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)