The Superior Anodic Oxidation of Aluminum Parts

The Superior Anodic Oxidation of Aluminum Parts

- Customized

- Aluminum parts anodic oxidation

- Customized

- Informations

- Description

The Superior Anodic Oxidation of Aluminum Parts

The Superior Anodic Oxidation of Aluminum Parts: Crafting Excellence in Industrial Manufacturing

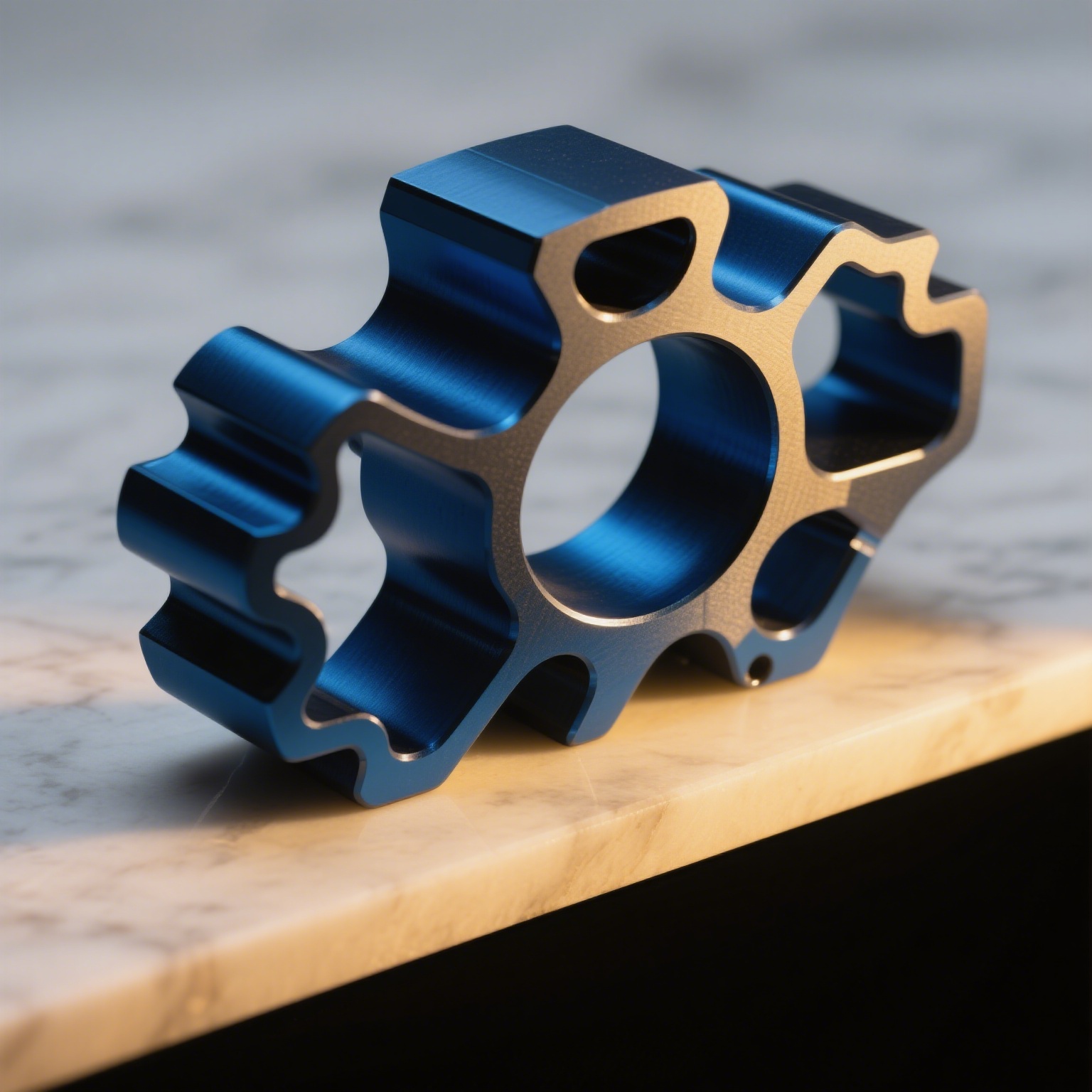

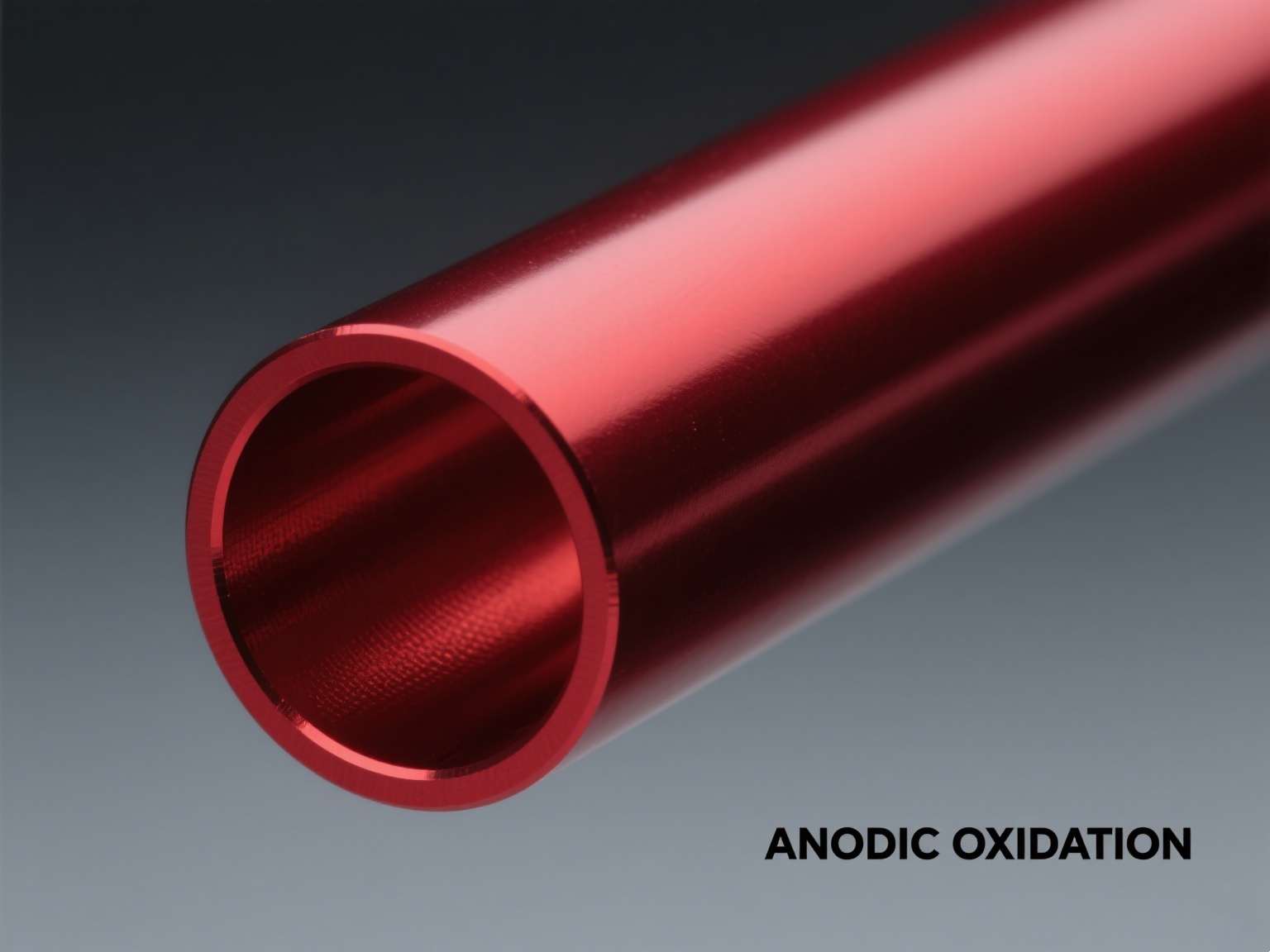

Anodic oxidation of aluminum parts stands as a cornerstone in modern manufacturing, renowned for its ability to transform ordinary aluminum components into durable, aesthetically appealing products. This electrochemical process creates a thick, porous oxide layer on the aluminum surface, offering unparalleled corrosion resistance—up to 10 times stronger than untreated aluminum—making it ideal for harsh environments. The oxidation layer’s porosity allows for vibrant color impregnation, enabling customization for industries like automotive and electronics.

Industry Applications: In automotive manufacturing, anodized aluminum parts reduce weight while withstanding road salt and UV exposure. Electronics benefit from its electrical insulation properties, seen in smartphone casings and heat sinks. The architectural sector leverages its weather resistance for curtain walls and facade systems, where longevity and visual appeal are paramount.

Core Advantages of Anodic Oxidation for Aluminum Parts

| Type | Aluminum parts anodic oxidation | Entrance size | Customized |