Ordinary Anodizing

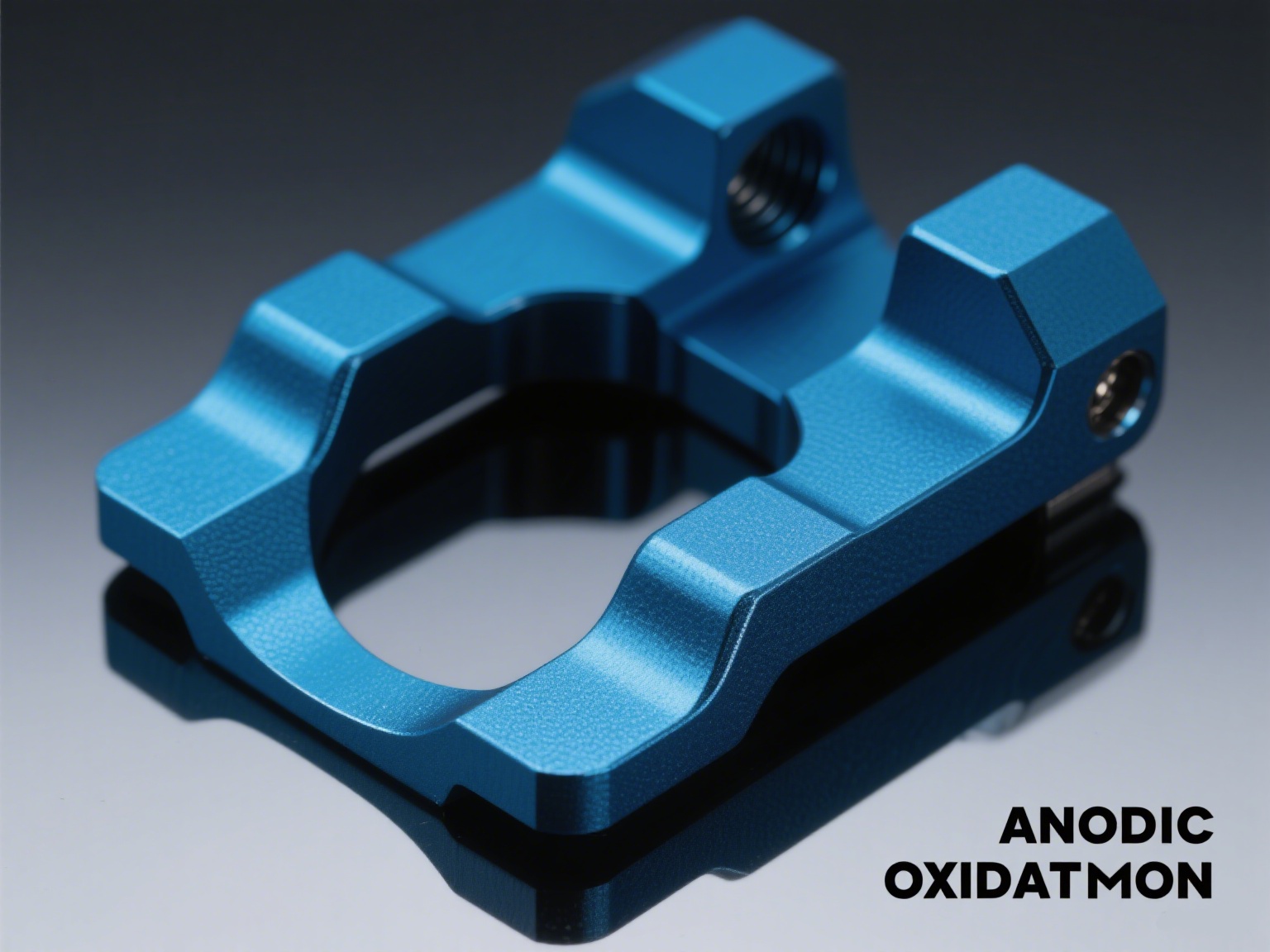

Surface Treatment, Anodic Oxidation. Prevents aluminum alloy from oxidizing and increases the durabi...

- Customized

- Aluminum anodizing

- Customized

- Informations

- Description

Surface Treatment, Anodic Oxidation. Prevents aluminum alloy from oxidizing and increases the durability and wear resistance of its surface.

Surface Treatment, Anodic Oxidation

Prevents aluminum alloy from oxidizing and increases the durability and wear resistance of its surface.

What are the characteristics and uses of anodic oxidation?

Generally, aluminum alloys are easy to oxidize. Although the oxide layer has a certain passivation effect.

However, as a result of long-term exposure, the oxide layer will still peel off and lose its protective effect.

Therefore, the purpose of anodic treatment is to use its easy oxidation characteristics to electrochemically

generate an oxide film to prevent further oxidation of the aluminum material and increase the mechanical

properties of the surface. When the aluminum alloy is anodic oxidized, a layer of aluminum oxide will form

on the surface. Since aluminum oxide is a very hard material, its wear resistance is increased. It is commonly

used for the surface treatment of parts that need to be frequently moved and rubbed against each other, such

as pistons, valves, cylinder liners, and other hard, wear-resistant, and highly corrosion-resistant aluminum alloy parts.

Anodic oxidation is generally more commonly used in primary colors or black. With the improvement of market

requirements for appearance, dyeing is another popular application of anodic aluminum oxide. During the anodic

oxidation process, a porous oxide layer is formed on the surface of the aluminum alloy. The structural characteristics

of the oxide film can be used for dyeing, dyeing into various bright colors to meet the needs of appearance diversity.

Alumina has high chemical stability and relatively low electrical conductivity. It has high insulation strength, high resistivity,

and low dielectric loss. It can be used in electric vehicle battery terminals, insulators, integrated circuit substrates, cable pins, etc.

Which metals can be anodic oxidized?

A material protection technology that forms a film on the surface of a metal material that acts as an anode in a specific electrolyte

by applying an external current. Most metal materials (such as stainless steel, zinc alloy, aluminum alloy, magnesium alloy, copper

alloy, titanium alloy) can be anodic oxidized in a suitable electrolyte.

Practical Application of Anodic Oxidation

Anodic oxidation is a method of changing the surface chemistry of metals and other substrates. It prevents corrosion, enhances

aesthetics, resists scratches, and is one of the most durable surface treatments available. There are three common anodic oxidation

processes for precision mechanical parts: chromic acid anodic oxidation, sulfuric acid anodic oxidation, and hard anodic oxidation.

More surface treatment services

We provide complex and precise aluminum parts products based on customer product specifications and industry standards,

combined with advanced CNC machine tools and manufacturing processes.

Shanfeng has comprehensive processing scale and efficient production capabilities, providing one-stop parts solutions, the most

cost-effective solution for customers.

| Type | Aluminum anodizing | Entrance size | Customized |