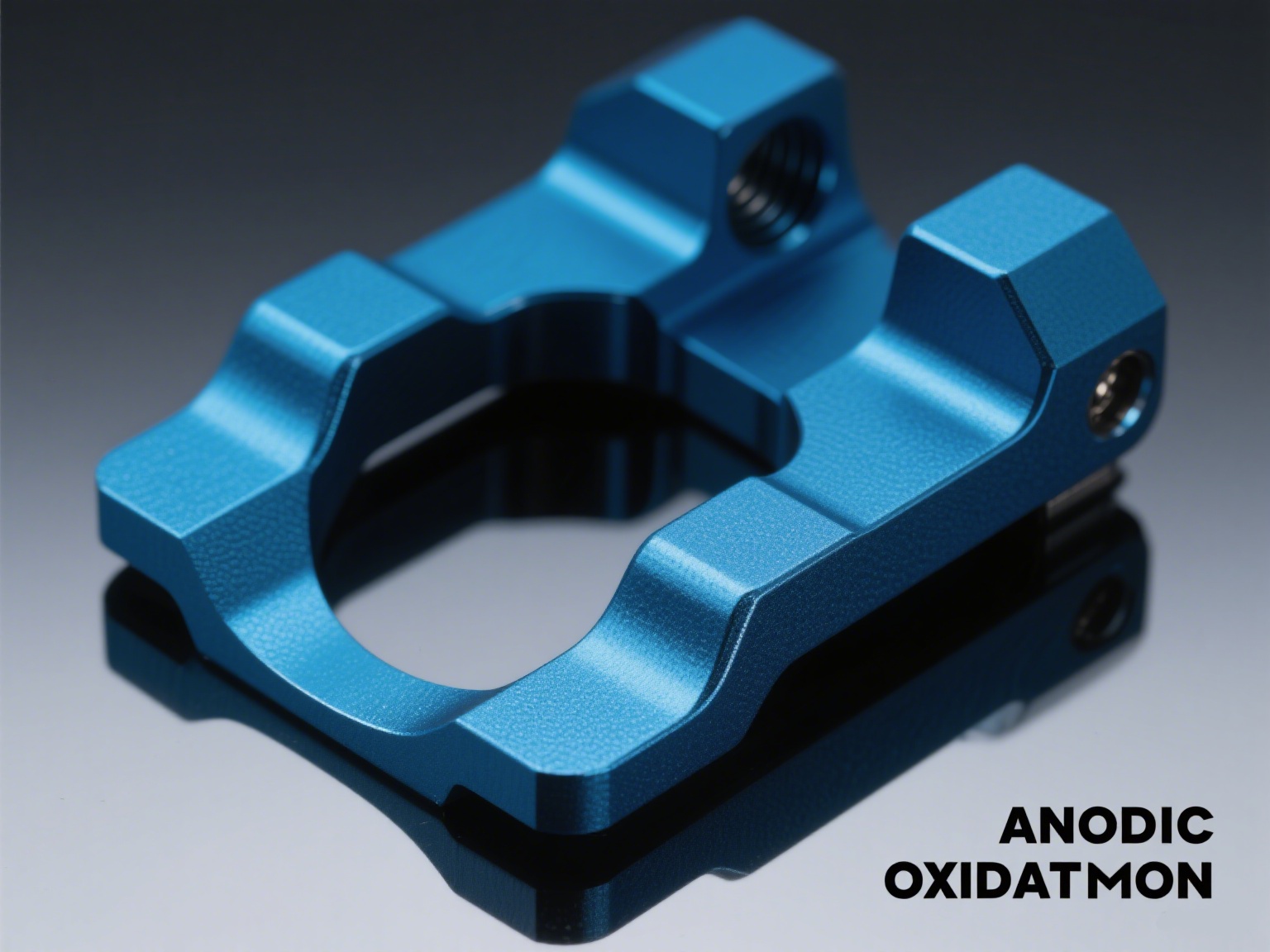

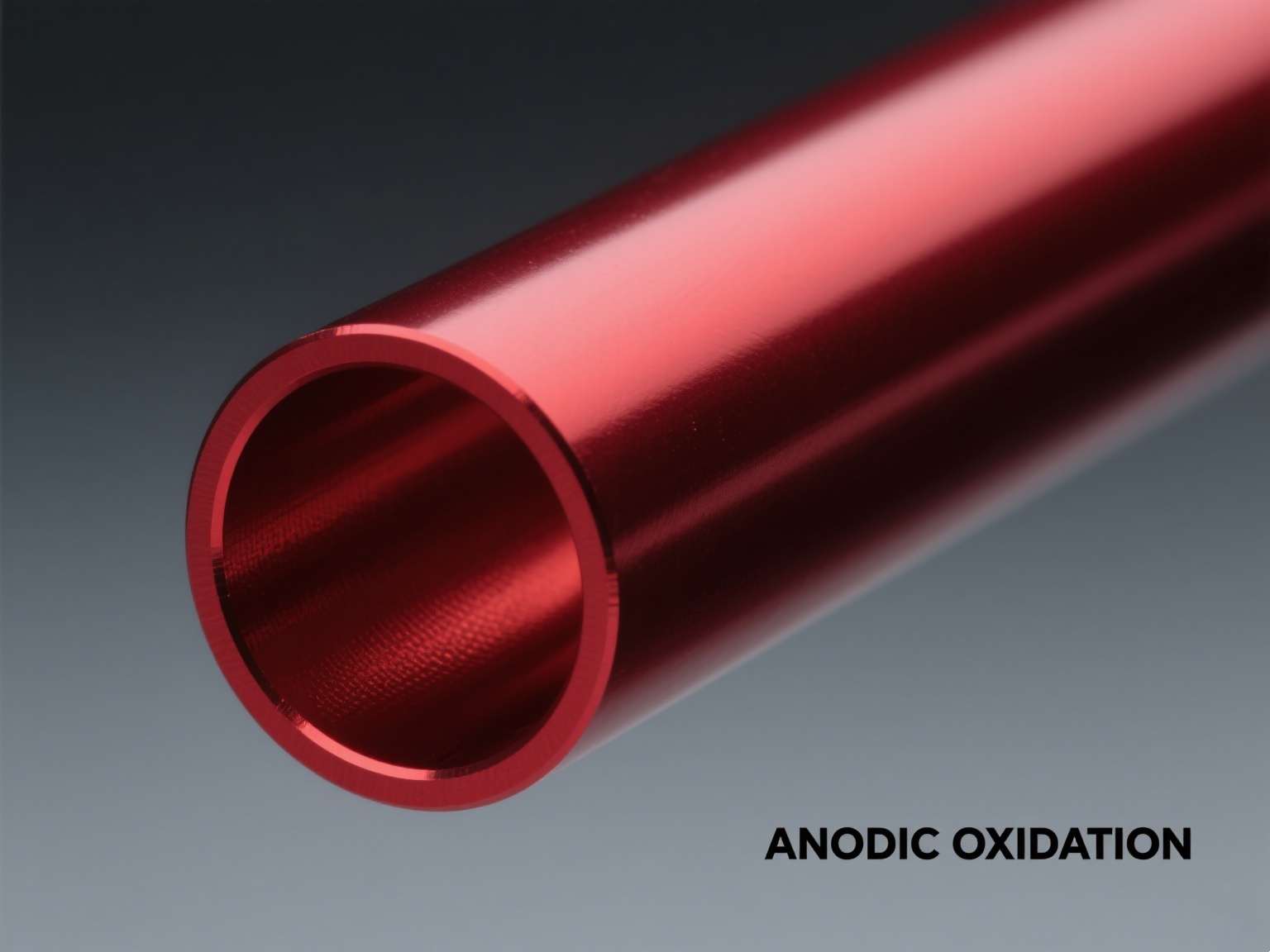

Unlocking the Potential of Anodic Oxidation for Aluminum Parts

Unlocking the Potential of Anodic Oxidation for Aluminum Parts

- Customized

- Aluminum parts anodic oxidation

- Customized

- Informations

- Description

Unlocking the Potential of Anodic Oxidation for Aluminum Parts

Unlocking the Potential of Anodic Oxidation for Aluminum Parts: Process Mastery and Market Impact

Anodic oxidation redefines aluminum part performance by merging functional benefits with aesthetic versatility. The process enhances surface hardness to 300–500 HV, protecting against wear and abrasion—essential for mechanical parts in machinery and robotics. Its thermal stability (withstanding up to 500°C) makes it suitable for engine components, while non-toxic sealing methods align with medical device regulations, such as in surgical instrument casings.

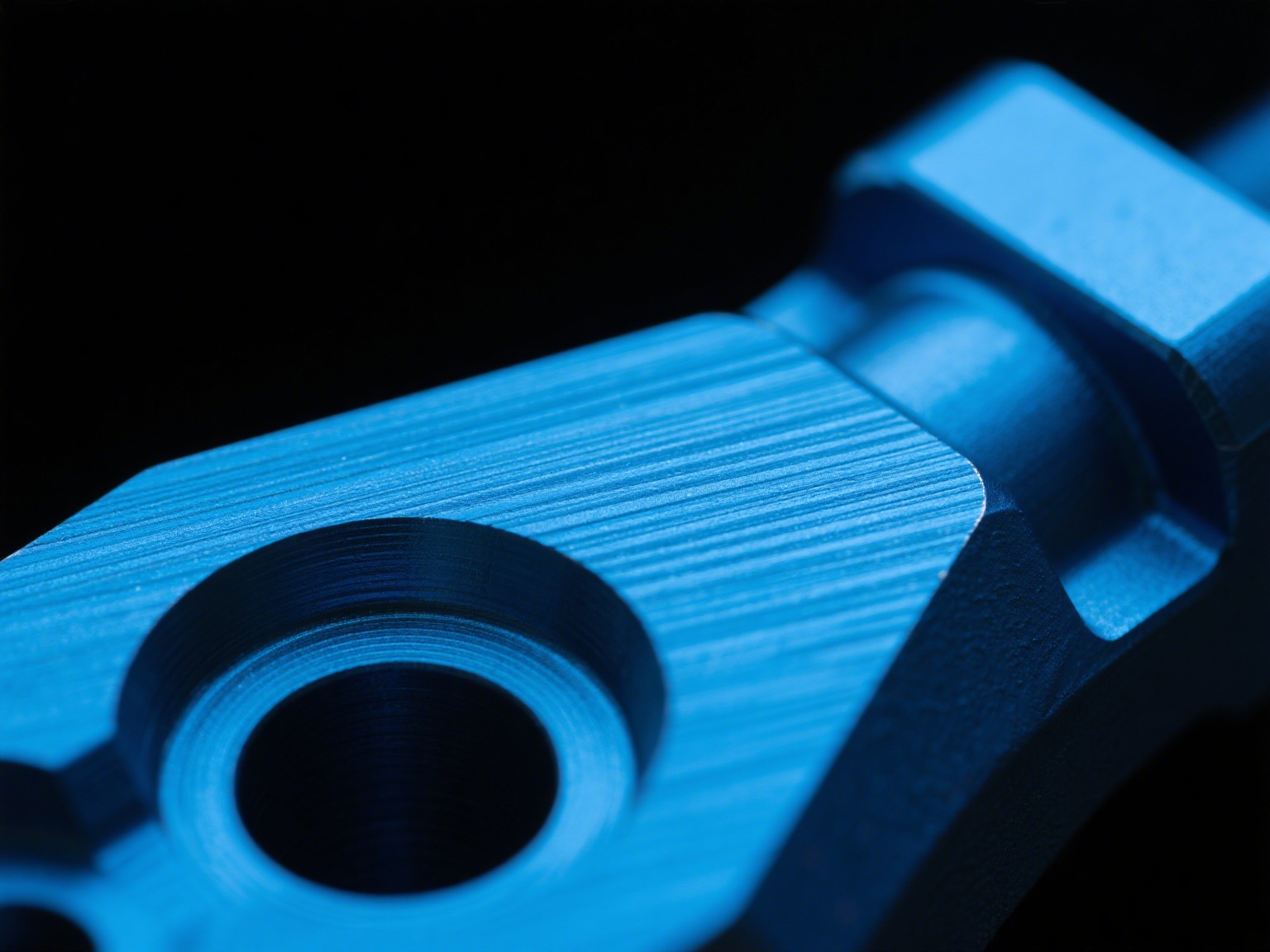

Machining Breakdown: Pre-treatment involves alkaline degreasing and acid activation to remove contaminants. The anodizing stage uses sulfuric acid baths (common for general applications) or chromic acid (for high-corrosion resistance), with voltage and temperature precisely controlled to avoid coating defects. Dyeing processes (organic or inorganic) follow, and hot water sealing converts the porous layer to a non-porous, stable structure.

Cross-Industry Applications: Aerospace relies on anodized aluminum for lightweight, corrosion-resistant aircraft components, meeting FAA standards for durability. The marine sector uses it for ship fittings, resisting saltwater corrosion. Even consumer goods—from camera bodies to kitchen utensils—benefit from its scratch-resistant finish and design flexibility.

Step-by-Step Anodic Oxidation Machining Process

Stage | Process Details | Key Parameters | Quality Control Standards |

Pre-Treatment | Degreasing (alkaline solution), chemical etching (nitric acid), and surface activation | Temperature: 50–70°C; immersion time: 5–10 minutes | Surface cleanliness: <5% oil residue (ISO 8502-6) |

Anodizing | Electrochemical oxidation in sulfuric/chromic/oxalic acid baths | Voltage: 12–24 V (sulfuric acid); temperature: 15–25°C; current density: 1–3 A/dm² | Coating uniformity: thickness variation <5% (ISO 7599) |

Dyeing | Organic/inorganic pigment impregnation for color customization | Dye concentration: 5–15 g/L; pH: 4–6; temperature: 20–40°C | Color consistency: ΔE <1.5 (CIE Lab) |

Sealing | Hot water/nickel acetate sealing to convert porous layer to non-porous structure | Temperature: 95–100°C; time: 10–30 minutes; pH: 5.5–7.0 | Porosity: <1% (ASTM B117); water absorption: <0.1 mg/cm² |

| Type | Aluminum parts anodic oxidation | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)