Medical Aluminum Parts Hard Anodizing

Anodizing Aluminum for Medical Aluminum Parts

- Customized

- Hard Anodizing

- Customized

- Informations

- Description

Anodizing Aluminum for Medical Aluminum Parts

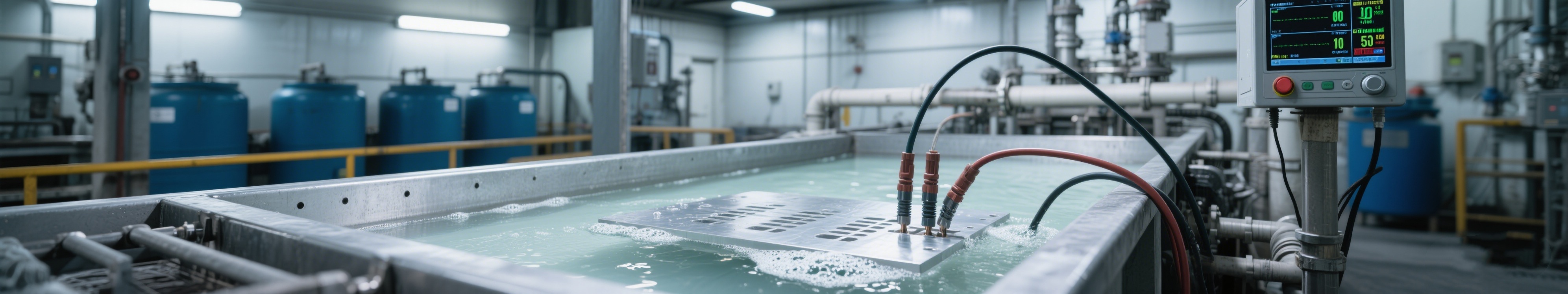

Definition of Hard Anodizing

Hard anodizing is an advanced metal surface treatment technology. Through anodic electrolytic treatment of metal workpieces in a specific electrolyte,

a dense and extremely hard aluminum oxide ceramic film layer is formed on the surface of the metal workpieces. This film layer not only has excellent

wear resistance and corrosion resistance, but also has a firm bond with the base metal and is not easy to fall off. It is widely used to improve the wear

resistance, corrosion resistance and surface hardness of metal parts, such as in the fields of aviation, automobiles, machinery, electronics, etc.

Differences between Hard Anodizing and Ordinary Anodizing:

1. Film layer thickness: The thickness of the ordinary oxide film layer is relatively thin; the thickness of the hard anodized film layer is generally >15μm,

and if it is too low, it cannot meet the requirement that the hardness is ≥300HV.

2. Surface condition: The surface of ordinary anodizing is relatively smooth, while the surface of hard anodizing is relatively rough (microscopically,

related to the surface roughness of the base metal).

3. Porosity: The porosity of ordinary anodizing is high; while the porosity of hard anodizing is low.

Process Flow of Hard Anodizing

The process flow of hard anodizing mainly includes three links: pretreatment, anodizing and post-treatment.

Pretreatment mainly involves cleaning, degreasing, rust removal and other treatments of metal workpieces to ensure that the surface of the workpieces is clean and free of impurities.

Anodizing is to put the pretreated metal workpieces into a specific electrolyte for anodic electrolytic treatment, so that an aluminum oxide ceramic film layer is formed on the surface of the workpieces.

Post-treatment is to carry out cleaning, drying, sealing and other treatments on the anodized workpieces to improve the corrosion resistance and wear resistance of the film layer.

Hard anodizing technology has the following significant characteristics:

1. High hardness: The hardness of the hard anodized film layer can reach above HV2000, which is much higher than the hardness of the ordinary anodized film layer.

2. Good wear resistance: Due to the high hardness and dense structure of the hard anodized film layer, it has good wear resistance.

3. Strong corrosion resistance: The hard anodized film layer has excellent corrosion resistance and can be used for a long time in harsh environments without being damaged.

4. Strong bonding force: The hard anodized film layer is firmly bonded to the base metal and is not easy to fall off.

5. Environmentally friendly and pollution-free: No toxic and harmful chemical substances are used during the hard anodizing process, and there is no pollution to the environment.

Application Fields of Hard Anodizing

Hard anodizing technology is widely used in the fields of aviation, automobiles, machinery, electronics, etc.

In the aviation field, hard anodizing technology is used to manufacture key components such as aircraft engine blades and turbine discs to improve their wear resistance and corrosion resistance.

In the automotive field, hard anodizing technology is used to manufacture components such as automobile engine pistons and valves to improve their wear resistance and service life. In the mechanical

field, hard anodizing technology is used to manufacture various precision mechanical parts, such as molds and cutting tools, to improve their surface hardness and wear resistance.

In the electronic field, hard anodizing technology is used to manufacture electronic products such as semiconductor devices and integrated circuits to improve their insulation performance and stability.

| Type | Hard Anodizing | Entrance size | Customized |