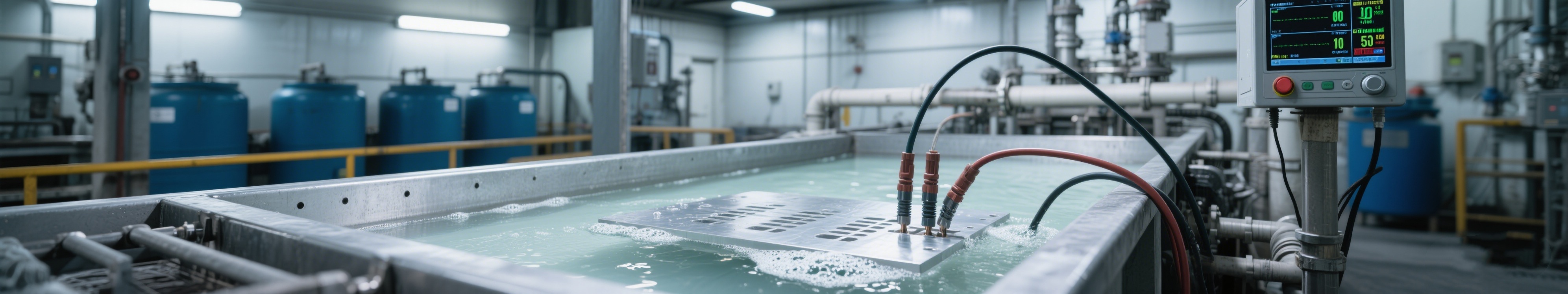

Aluminum parts Hard Anodizing

Thick, wear-resistant oxide layer on aluminumHard anodizing is a process that creates a thick, wear-...

- Customoized

- Aluminum Anodizing

- Customoized

- Informations

- Description

Thick, wear-resistant oxide layer on aluminumHard anodizing is a process that creates a thick, wear-resistant oxide layer on aluminum12345.

Definition of Hard Anodizing

Hard anodizing is a thick-film anodizing method, which is a special anodizing surface treatment process for aluminum and aluminum alloys.

Through this process, the maximum thickness of the anodized film can reach about 250 micrometers. On pure aluminum, an oxidized film with

a microhardness of 1500 kg/mm² can be obtained, while on aluminum alloys, an oxidized film with a microhardness of 400 to 600 kg/mm² can be obtained.

The oxidized film layer has poor thermal conductivity, with a melting point of 2050 °C and a relatively large resistivity. After being sealed (immersed in insulating

substances or paraffin), the breakdown voltage can reach 2000 V. It has high corrosion resistance in the atmosphere, high wear resistance, and is also an ideal thermal

insulation film layer. It also has good insulation and a series of advantages such as a firm combination with the base metal.

Advantages of Hard Anodizing

1. After hard anodizing of aluminum alloys, the surface hardness can reach about HV500;

2. The thickness of the oxidized film is 25-250 μm;

3. Strong adhesion. According to the characteristics of the oxide generated by hard anodizing: 50% of the generated oxide film penetrates into the aluminum alloy,

and 50% adheres to the surface of the aluminum alloy;

4. Good insulation: The breakdown voltage can reach 2000 V;

5. Good wear resistance: For aluminum alloys with a copper content exceeding 2%, the maximum wear index is 3.5 mg/1000 revolutions. The wear index of all other

alloys should not exceed 1.5 mg/1000 revolutions.

6. Non-toxic: The oxidized film and the electrochemical process used to produce the anodized film should be harmless to the human body.

Currently, the following two types of hard anodizing are widely used:

(1) Direct current method of sulfuric acid hard anodizing;

(2) AC-DC overlapping method of oxalic acid hard anodizing.

Among them, the sulfuric acid method is a hard anodizing method that is currently widely used.

Application Fields of Hard Anodizing

It is mainly applied to aluminum and aluminum alloy parts that require high wear resistance, heat resistance, and good insulation performance.

Products that have undergone hard anodizing have a series of advantages such as extremely high corrosion resistance and wear resistance, good insulation,

and a firm combination with the base metal. Therefore, they are widely used in fields such as the national defense industry, mechanical parts manufacturing industry,

medical accessories, and electronic accessories.

| Type | Aluminum Anodizing | Entrance size | Customoized |