Elevating Automotive Performance: The Ingenuity of Our Aluminum Parts

Elevating Automotive Performance: The Ingenuity of Our Aluminum Parts

- Customized at your need

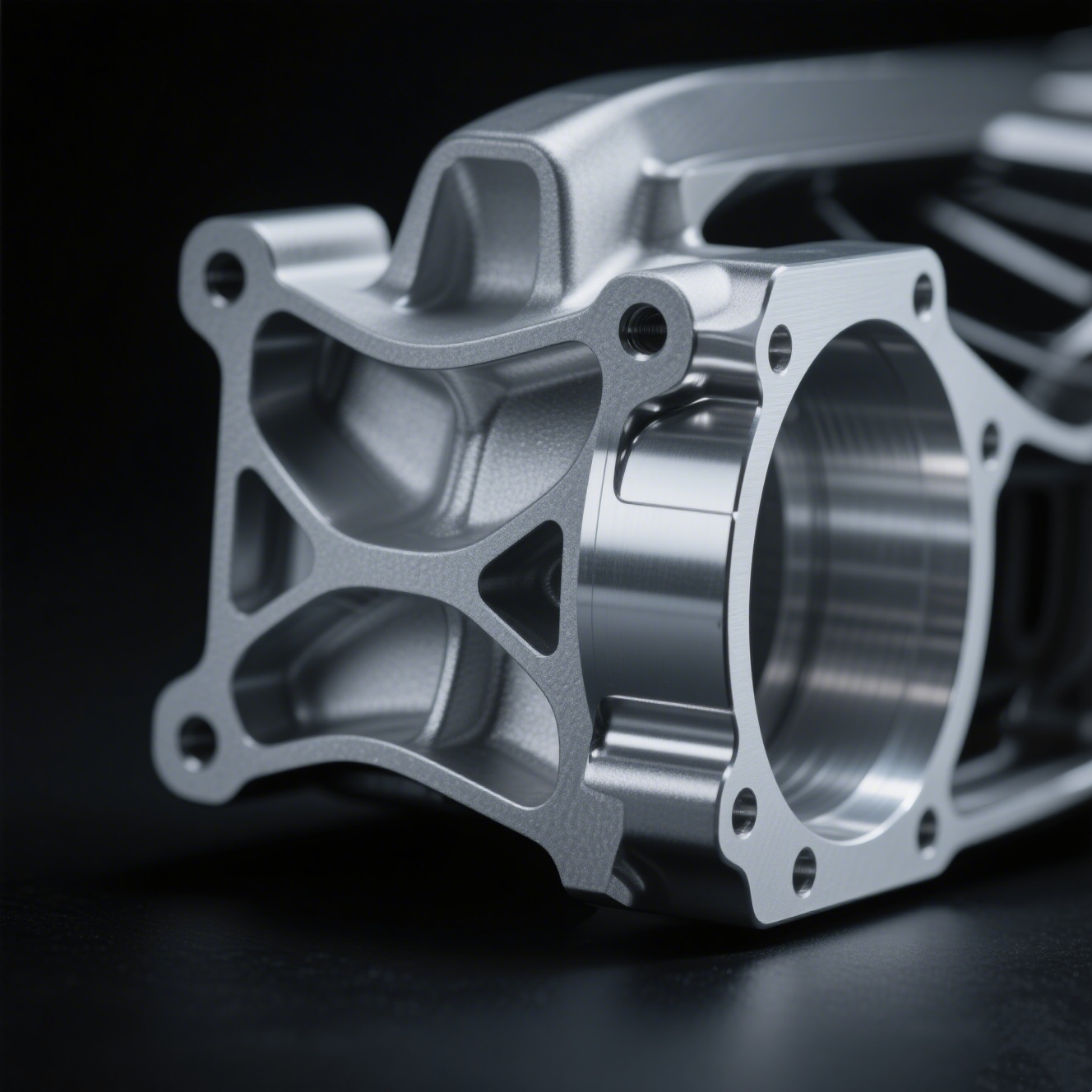

- Automotive Aluminum Parts

- Customized at your need

- Informations

- Description

Elevating Automotive Performance: The Ingenuity of Our Aluminum Parts

Elevating Automotive Performance: The Ingenuity of Our Aluminum Parts

Engineering Excellence: The Processes That Set Us Apart

3D Printed Aluminum Structures: Utilizing state-of-the-art additive manufacturing, we can produce complex lattice structures that were once impossible with traditional methods. These structures are up to 35% lighter than solid counterparts while maintaining the same strength, making them ideal for components like engine mounts and intake manifolds.

Cold Forging Reinvention: Our cold forging process, enhanced with ultrasonic vibration technology, allows us to shape aluminum at room temperature with minimal material loss. The result is parts with a finer grain structure, increasing their tensile strength by 25% compared to hot-forged alternatives.

Plasma Electrolytic Oxidation (PEO): This advanced surface treatment creates a ceramic-like coating on the aluminum surface, far superior to standard painting or plating. It offers exceptional resistance to chemicals, UV rays, and abrasion, ensuring the parts retain their pristine appearance and performance for years.

The Distinctive Traits: Beyond the Basics

Feature | Our Innovation | Industry Norm | Advantage |

Fatigue Resistance | 10,000+ cycles at maximum load without failure | 6,000-8,000 cycles | Ensures long-term reliability in high-stress areas like suspension systems |

Formability | Can be shaped into intricate designs with tight tolerances (±0.02mm) | Tolerances of ±0.1mm or more | Enables the creation of sleek, aerodynamic parts that fit perfectly |

Cost-Effectiveness | Reduced production time by 40% due to advanced processes | Longer production cycles with higher material waste | Lower overall costs without compromising quality |

Compatibility | Compatible with various joining methods, including adhesive bonding and friction stir welding | Limited to traditional welding and bolting | Offers more design flexibility for vehicle manufacturers |

Applications That Transform the Drive

Engine Components: Our 3D printed cylinder heads and intake manifolds optimize airflow, increasing engine efficiency by 10% and reducing emissions. The lightweight design also reduces the engine's overall weight, improving the vehicle's handling.

Brake Systems: Cold-forged aluminum brake calipers offer superior heat dissipation, reducing brake fade by 30% during intense driving. This ensures consistent braking performance, even in the most demanding conditions.

Electrical System Enclosures: PEO-treated aluminum enclosures protect sensitive electrical components from moisture, dust, and corrosion. They are also lightweight, contributing to the vehicle's overall energy efficiency.

Leading the Way in Automotive Evolution

Automotive aluminum parts are no longer just a choice for weight reduction—they are a necessity for building the vehicles of the future. At ShanFeng, we are committed to pushing the boundaries of what aluminum can achieve.

Our parts are designed to work in harmony with the latest automotive technologies, from electric powertrains to advanced driver-assistance systems.

| Type | Automotive Aluminum Parts | Entrance size | Customized at your need |