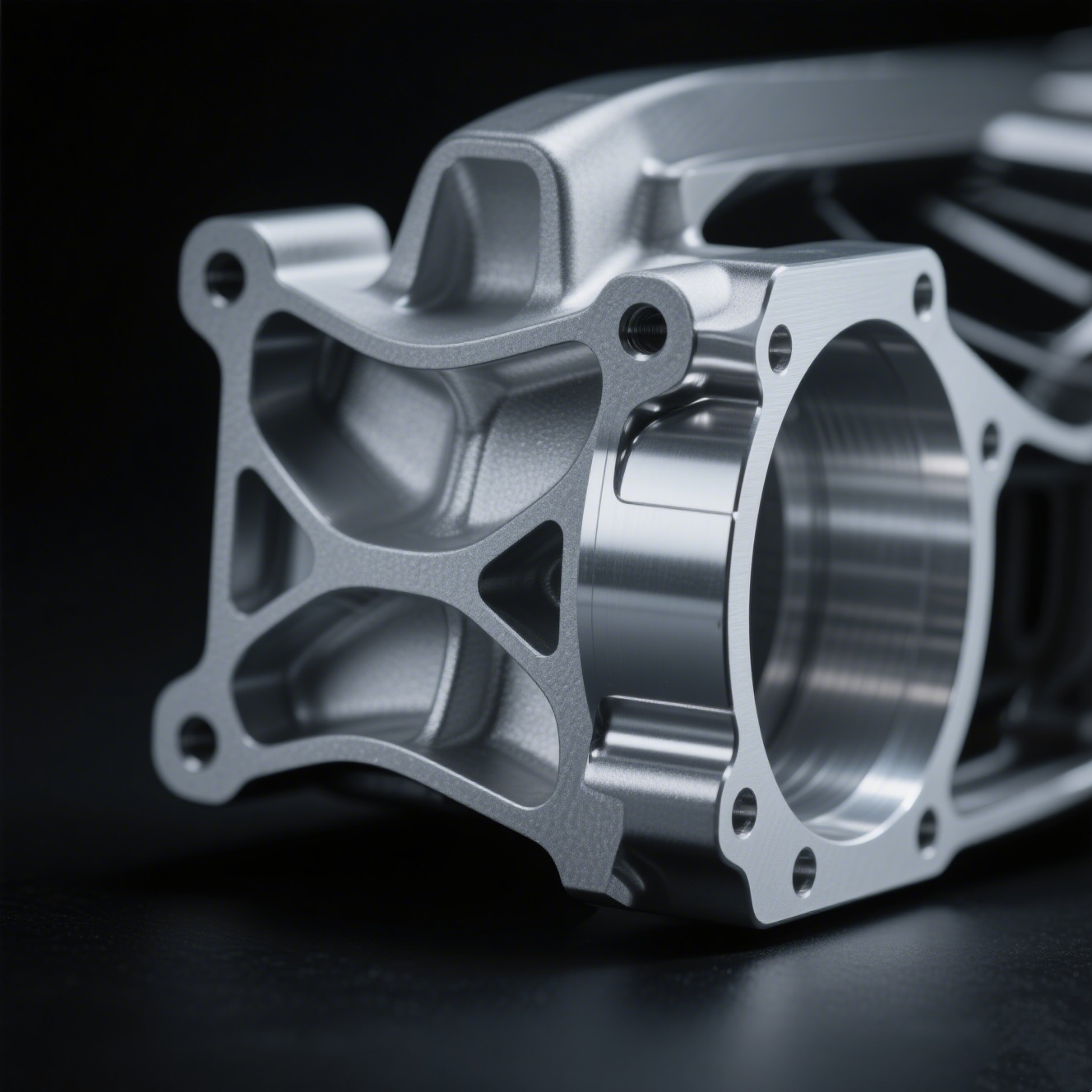

Aluminum Alloy Lightweight Components

Aluminum Alloy Lightweight Components

- Customized at your need

- Automotive Aluminum Parts

- Customized at your need

- Informations

- Description

Aluminum Alloy Lightweight Components

Crafting the Future of Mobility: ShanFeng Factory's Innovations in Aluminum Alloy Lightweight Components

In the fast - evolving landscape of automotive engineering, the pursuit of lightweight solutions has become a cornerstone of progress. At ShanFeng Factory, we don't just manufacture aluminum alloy auto components; we engineer a new paradigm of efficiency and performance, where each piece is a testament to our dedication to pushing the boundaries of what's possible.

Pioneering Materials: The Science Behind Our Alloys

Our commitment to excellence begins with the selection of raw materials. We source high - quality aluminum with a purity of 99.8%, which forms the basis of our advanced alloys. Through rigorous research and development, we've formulated a unique blend for our 7 - series aluminum alloy, with zinc content ranging from 5.1 - 6.1%, magnesium from 2.1 - 2.9%, and copper at 1.2 - 2.0%. This precise combination results in an alloy with an impressive tensile strength of 540MPa, making it ideal for high - stress components.

The process of creating these alloys is a marvel of precision. In our state - of - the - art melting facilities, the temperature is controlled to within ±5℃, ensuring the perfect fusion of elements. The molten alloy is then cast into billets using a specialized process that guarantees a uniform grain structure, with a grain size of less than 50μm, laying the foundation for superior mechanical properties.

Cutting - Edge Manufacturing: Where Precision Meets Productivity

Process | Equipment Type | Key Parameter | Daily Output | Rejection Rate |

Hot Extrusion | SMS Group Press | Extrusion Speed: 15 - 30 m/min | 1800 pieces | 0.04% |

Powder Metallurgy | Hosokawa Micronizer | Particle Size: 5 - 20μm | 600 pieces | 0.02% |

Electrochemical Polishing | Custom - Built Line | Surface Roughness: Ra≤0.08μm | 2200 pieces | 0.03% |

Final Testing | Bruker Contour GT - K | Measurement Accuracy: 0.0005mm | 2000 pieces | 0.01% |

Our hot extrusion line is a masterpiece of engineering. The SMS Group press delivers consistent pressure, ensuring that each extruded component meets exacting dimensional standards, with a tolerance of ±0.05mm. The powder metallurgy process, on the other hand, allows us to create complex shapes with intricate details that would be impossible with traditional manufacturing methods. The fine particle size of the powder ensures a dense, homogeneous structure, enhancing the component's performance.

In the electrochemical polishing workshop, our custom - built line transforms the surface of the components, giving them a mirror - like finish while also improving their corrosion resistance. This process not only enhances the aesthetic appeal but also reduces friction, contributing to improved overall efficiency.

Beyond Performance: Sustainability in Every Component

At ShanFeng Factory, we believe that true innovation goes hand in hand with sustainability. Our aluminum alloy components are not only lightweight and strong but also highly recyclable, with a recycling efficiency of 95%. This means that at the end of a vehicle's life, our components can be melted down and reused, reducing the environmental impact of the automotive industry.

Our production processes are also designed with sustainability in mind. We've implemented a closed - loop water recycling system that reduces water consumption by 70% compared to traditional manufacturing facilities. Additionally, our energy - efficient furnaces and machinery have cut down on energy usage by 35%, making us a leader in green manufacturing.

The components we produce have a significant impact on vehicle sustainability. Our lightweight suspension arms reduce the overall weight of the vehicle by 45%, leading to a 12 - 18% reduction in fuel consumption. For electric vehicles, this translates to an increase in range of 15 - 25%, addressing one of the key challenges in the adoption of electric mobility.

At ShanFeng Factory, we're not just making components; we're shaping the future of transportation. Every component that leaves our facility is a symbol of our commitment to innovation, precision, and sustainability. Join us on this journey as we continue to redefine what's possible in the world of aluminum alloy lightweight auto components.

| Type | Automotive Aluminum Parts | Entrance size | Customized at your need |

Get the latest prices? We will respond as soon as possible (within 12 hours)