Aluminum Reimagined: The Silent Revolution in Automotive Engineering

Aluminum Reimagined: The Silent Revolution in Automotive Engineering

- Customized at your need

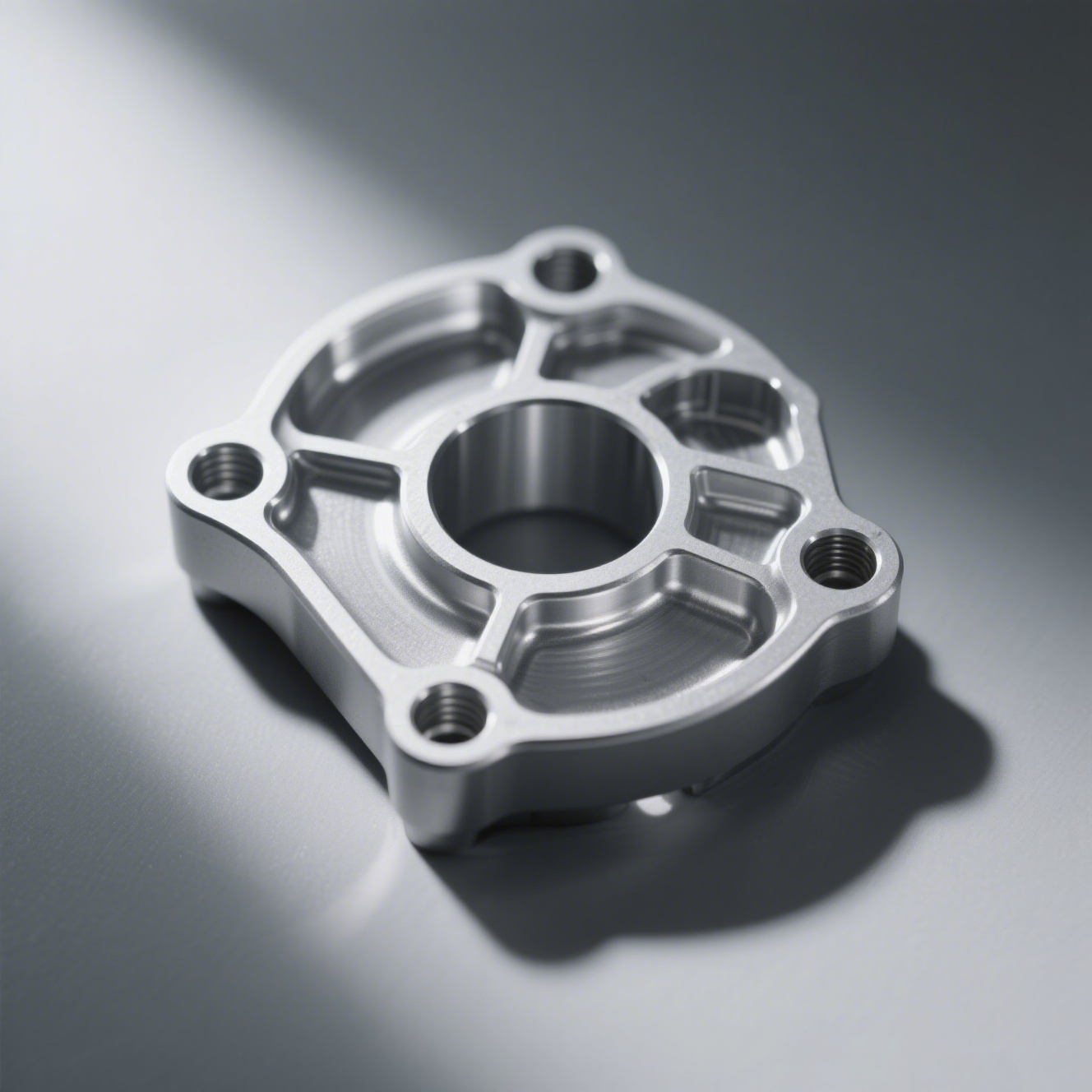

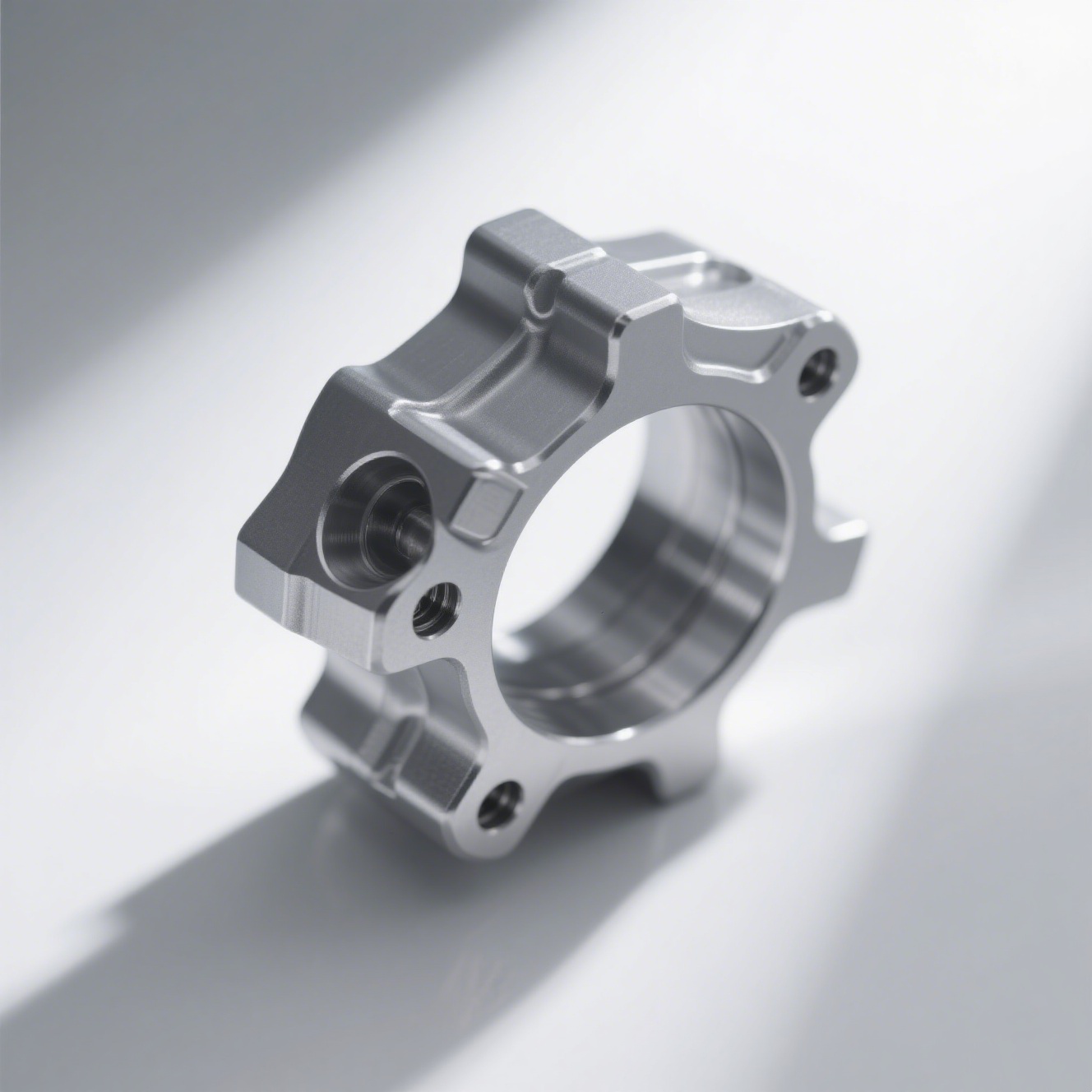

- Automotive Aluminum Parts

- Customized at your need

- Informations

- Description

Aluminum Reimagined: The Silent Revolution in Automotive Engineering

Aluminum Reimagined: The Silent Revolution in Automotive Engineering

Forging the Future: How Modern Aluminum Parts Take Shape

Adaptive Roll Forming: Imagine a machine that “learns” as it works. Adaptive roll forming uses AI-driven sensors to adjust pressure and speed in real time, bending aluminum sheets into complex, curved profiles (think roof rails or door sills) with zero stress fractures. It's like metal ballet—graceful, precise, and infinitely repeatable.

Ultrasonic Additive Manufacturing (UAM): Why weld when you can "stitch"aluminum layers together? UAM uses high-frequency vibrations to bond aluminum foils into solid 3D structures, creating parts with internal channels (for coolant or wiring) that would be impossible to drill. The result? 40% lighter components with embedded functionality.

Plasma Arc Texturing: Forget "polished"or "matte." Plasma arc texturing blasts the aluminum surface with controlled plasma, creating micro-patterns that trap light, repel water, and reduce friction. It's a finish that's both functional (less wind resistance) and striking (a metallic sheen that shifts with every angle).

The DNA of Innovation: What Makes These Parts Game-Changers

Trait | Modern Aluminum Advantage | Legacy Limitations | Industry Impact |

Weight vs. Strength | 30% lighter than steel, but with 90% of the load-bearing capacity | Trade-offs forced: lighter meant weaker, stronger meant heavier | EVs gain 20+ miles of range; ICE vehicles cut CO₂ emissions by 12% |

Durability | Resists corrosion 3x longer than untreated aluminum (thanks to ceramic-infused coatings) | Prone to rust; required frequent maintenance | Parts last 150,000+ miles without degradation—doubling component lifespans |

Design Freedom | Can be molded into 70% more complex shapes than steel (no more “boxy” constraints) | Limited by metal's rigidity; simple geometries only | Vehicles with sleeker aerodynamics (15% less drag) and more interior space |

Sustainability | 95% recyclable at end-of-life (with zero loss of material properties) | Recycled aluminum often degraded; high energy use in processing | Cuts automotive waste by 60%; reduces production carbon footprint by 55% |

Where Aluminum Takes the Wheel: Applications Redefining Performance

Battery Frames for EVs: UAM-built battery frames aren't just containers—they're structural. With internal coolant channels and crash-absorbing honeycomb cores, they protect batteries during impacts while slashing 15kg from the vehicle's weight. Range anxiety? Meet its match.

Suspension Arms: Adaptive roll-formed suspension arms flex slightly under pressure, absorbing road bumps instead of transferring them to the cabin. The result? A ride so smooth, it feels like gliding—without sacrificing handling precision.

Engine Blocks: Plasma-textured aluminum engine blocks dissipate heat 25% faster than cast iron, allowing engines to run hotter (and more efficiently) without overheating. It's like giving the engine its own built-in cooling system.

The Ripple Effect: How Aluminum is Shifting the Industry

| Type | Automotive Aluminum Parts | Entrance size | Customized at your need |