Automotive Aluminum Lightweight Components

Automotive Aluminum Lightweight Components

- Customized at your need

- Automotive Aluminum Parts

- Customized at your need

- Informations

- Description

Automotive Aluminum Lightweight Components

Redefining Automotive Excellence: The Innovation Behind Our Aluminum Components

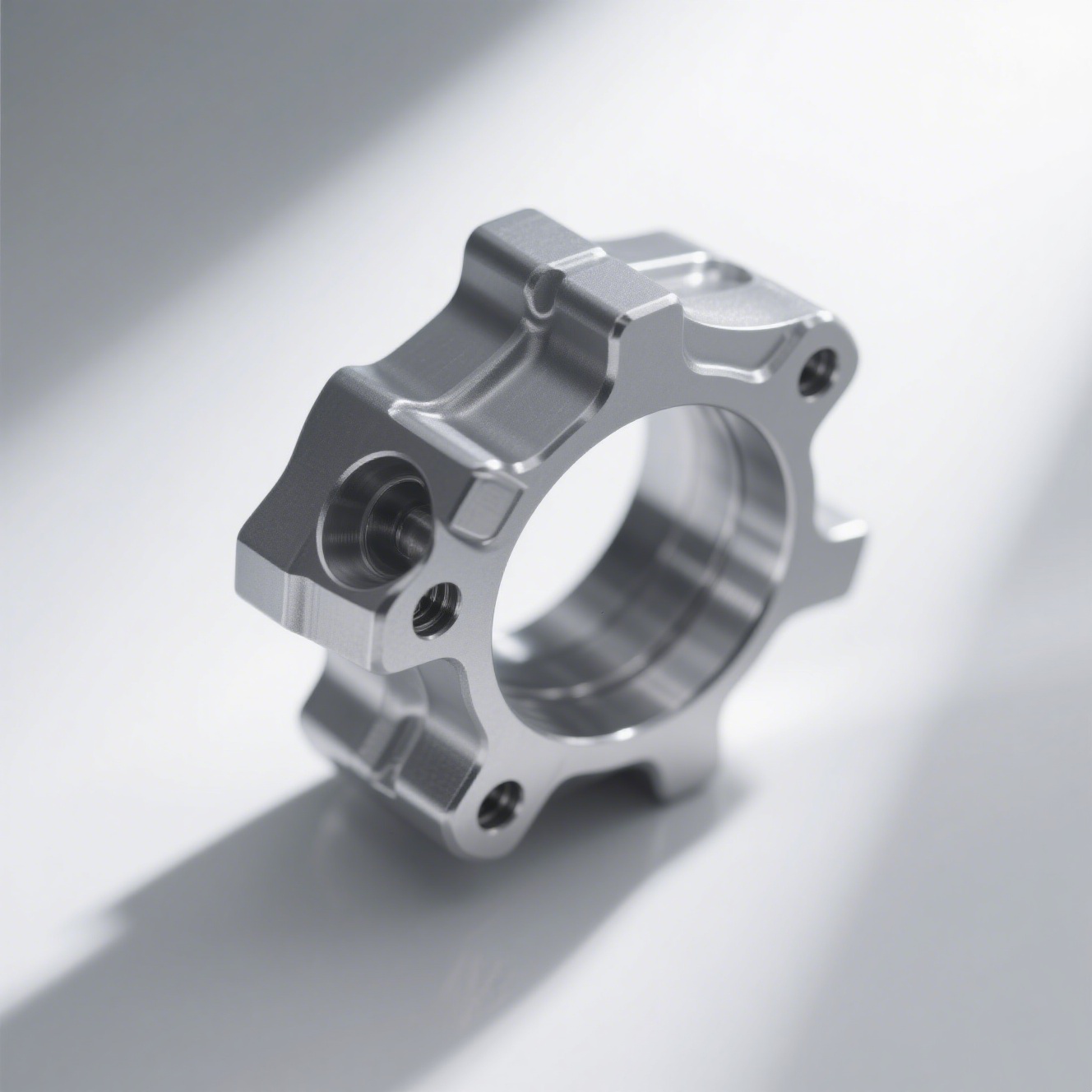

Crafted by Innovation: The Art of Shaping Aluminum

Hydroforming 2.0: We've revolutionized traditional hydroforming by integrating real-time pressure mapping, allowing us to shape complex geometries (think intricately curved chassis brackets or hollow structural beams) with zero material waste. This isn't just forming—it's sculpting metal like clay, but with the rigidity of steel.

Laser Microwelding: Traditional welding leaves seams; our laser microwelding creates bonds thinner than a human hair. This means lighter joints with 30% higher fatigue resistance, perfect for high-stress components like suspension arms.

Nanostructured Anodization: Beyond aesthetics, our anodization process embeds nanoscale ceramic particles into the aluminum surface, creating a finish that's 50% harder than standard treatments—scratch-resistant, corrosion-proof, and with a matte-silver sheen that catches light like no other.

Why Our Aluminum Parts Stand Out: More Than Just “Lightweight”

Feature | Our Innovation | Industry Standard | Impact |

Weight Reduction | Up to 45% lighter than steel equivalents (without strength loss) | Average 20-30% reduction | Boosts fuel efficiency by 8-12% for ICE vehicles; extends EV range by 15%+ |

Strength-to-Weight Ratio | 780 MPa tensile strength at 2.7g/cm³ density | 600 MPa at 2.8g/cm³ | Enables thinner, stronger components (e.g., subframes that absorb 20% more crash energy) |

Thermal Conductivity | 220 W/(m·K) (optimized for heat dissipation) | 180 W/(m·K) | Prevents overheating in EV battery enclosures and brake calipers |

Sustainability | 100% recycled aluminum content (with 95% energy savings vs. primary aluminum) | 30-50% recycled content | Cuts carbon footprint by 70% per component |

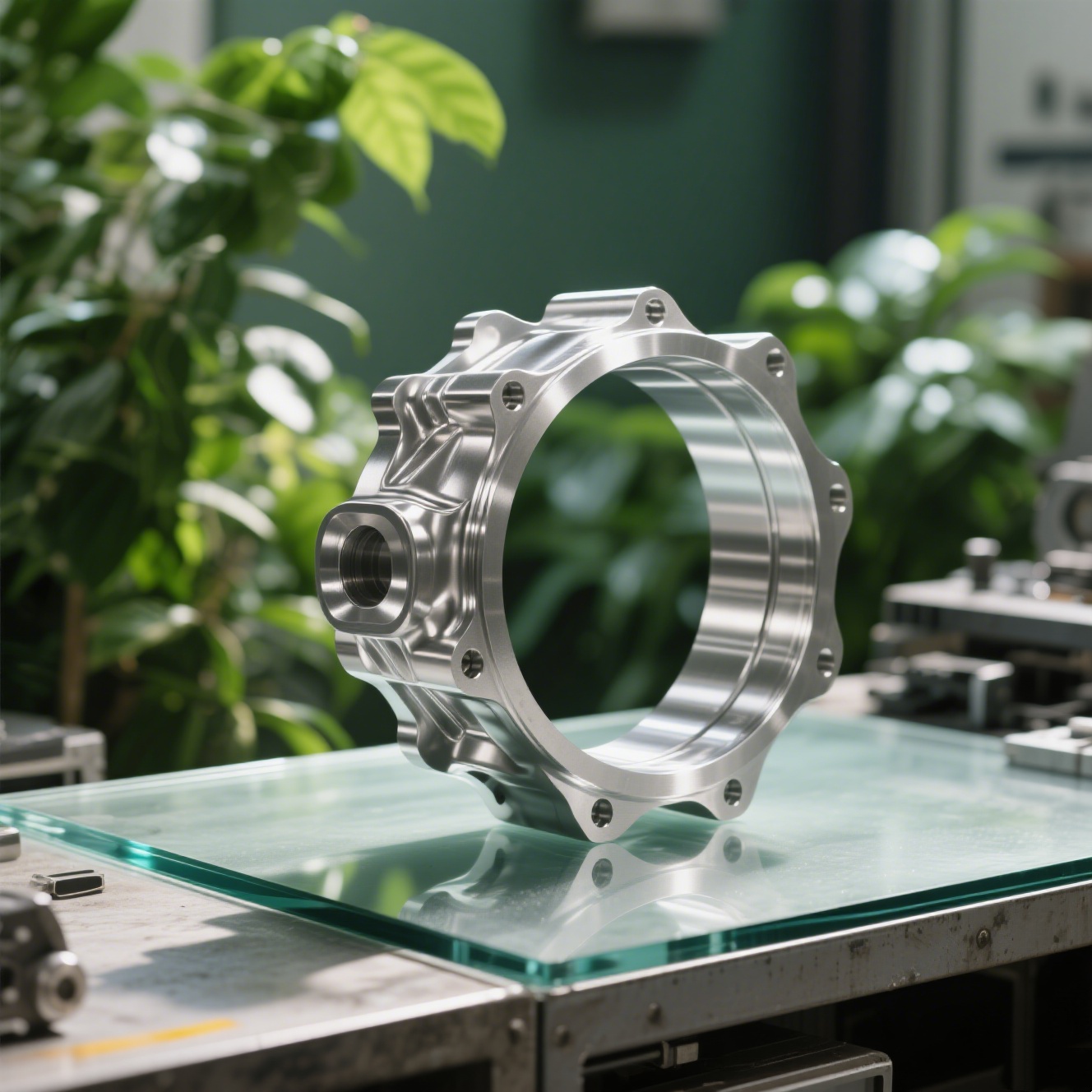

Where Innovation Drives the Road: Applications That Matter

EV Battery Housings: Lightweight yet impenetrable, our nanostructured aluminum enclosures protect batteries from impact while dissipating heat 30% faster than steel, extending battery life by up to 200 charge cycles.

Adaptive Suspension Links: Laser-welded and hydroformed to flex under stress, these links adjust to road conditions in milliseconds, reducing vibration by 40% for a smoother ride.

Aerodynamic Body Panels: Thinner (0.8mm) but stronger than conventional panels, they slice through air with 15% less drag, turning every highway drive into an efficiency masterclass.

The Future of Lightweighting: It's Already Here

| Type | Automotive Aluminum Parts | Entrance size | Customized at your need |