Lightweight auto components

Lightweight auto components

- Customized at your need

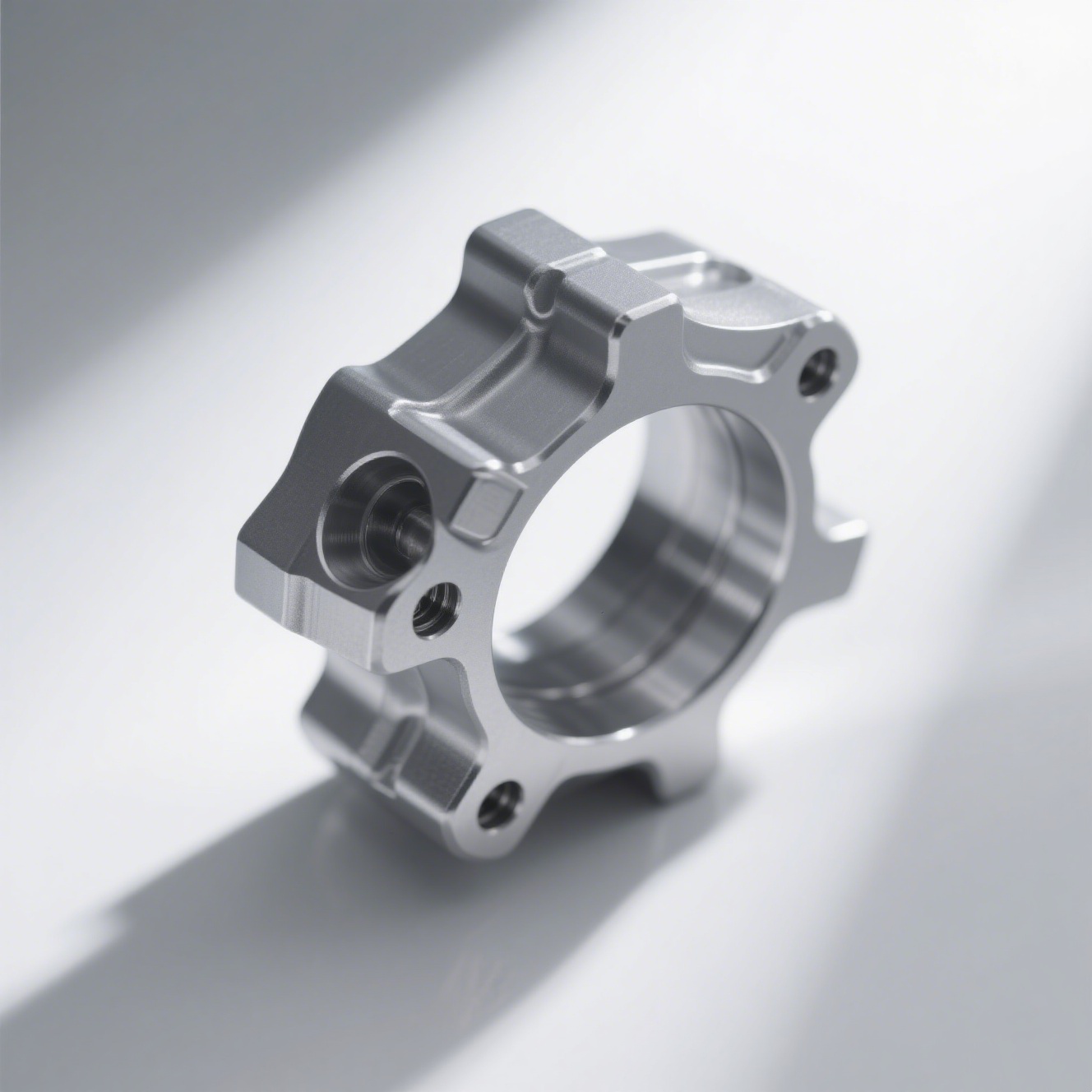

- Automotive Aluminum Parts

- Customized at your need

- Informations

- Description

Lightweight auto components

Lightweight Auto Components: Revolutionizing the Automotive Industry

1. Introduction

In the contemporary automotive industry, the pursuit of lightweight auto components has emerged as a pivotal trend, driven by multiple factors. With the increasing stringency of global emission regulations and the growing consumer demand for more fuel - efficient and high - performance vehicles, automakers are constantly exploring innovative ways to reduce vehicle weight without compromising safety or functionality. Lightweighting not only contributes to better fuel economy and reduced emissions but also enhances vehicle performance, handling, and acceleration.

2. The Advantages of Lightweight Auto Components

2.1 Fuel Efficiency Improvement

One of the most significant benefits of lightweight auto components is the substantial improvement in fuel efficiency. Research has shown that for every 10% reduction in vehicle weight, fuel efficiency can increase by 6 - 8%. When a vehicle is lighter, the engine has to work less to move it, consuming less fuel in the process. For example, if a vehicle's body weight, which typically accounts for about 30% of the total vehicle mass, is reduced, under no - load conditions, a significant portion of the fuel consumption (about 70% is used for moving the body) can be saved. This not only saves costs for consumers but also helps in reducing the overall carbon footprint of the transportation sector.

2.2 Performance Enhancement

Lightweight components play a crucial role in enhancing vehicle performance. A lighter vehicle has less inertia, which means it can accelerate more quickly and brake more efficiently. The reduced weight also improves the vehicle's handling and maneuverability. For instance, in high - performance sports cars, the use of lightweight materials in components such as the chassis, suspension, and body panels allows for better cornering and a more responsive driving experience. The engine can also be downsized without sacrificing performance, as it has to move less mass, resulting in a more efficient power - to - weight ratio.

2.3 Safety Augmentation

Contrary to the common perception that lighter vehicles are less safe, lightweight auto components can actually enhance safety. Lighter vehicles have a shorter braking distance due to reduced inertia. In addition, modern lightweight materials are designed to be highly strong and impact - resistant. For example, advanced high - strength steels and carbon fiber composites used in vehicle structures can absorb and distribute crash energy more effectively, protecting the occupants inside the vehicle. Moreover, the use of lightweight materials can help in better weight distribution, improving the vehicle's stability and reducing the risk of roll - overs.

3. Common Lightweight Materials Used in Auto Components and Their Properties

Material | Density (g/cm³) | Tensile Strength (MPa) | Specific Strength (MPa/(g/cm³)) | Cost (Relative to Steel) |

Aluminum | 2.7 | 90 - 600 | 33 - 222 | 2 - 3 times |

Magnesium | 1.74 | 150 - 300 | 86 - 172 | 3 - 5 times |

Carbon Fiber Reinforced Polymer (CFRP) | 1.5 - 2.0 | 1000 - 7000 | 500 - 3500 | 5 - 10 times |

Advanced High - Strength Steel (AHSS) | 7.85 | 500 - 2000 | 64 - 255 | Similar |

3.1 Aluminum

Aluminum has been widely adopted in the automotive industry for its low density, high strength - to - weight ratio, corrosion resistance, and ease of fabrication. It is used in various components such as engine blocks, wheels, and body panels. For example, aluminum engine blocks are much lighter than their cast - iron counterparts, reducing the overall weight of the vehicle and improving fuel efficiency. The high corrosion resistance of aluminum ensures that components made from it have a longer lifespan, even in harsh environmental conditions.

3.2 Magnesium

Magnesium is one of the lightest structural metals available. It is increasingly being used in automotive components such as instrument panels, seat frames, and some powertrain components. Despite its relatively high cost, the significant weight savings it offers make it an attractive option for automakers aiming to meet strict fuel efficiency and emissions standards. Magnesium alloys can provide a good balance of strength and weight, contributing to overall vehicle lightweighting.

3.3 Carbon Fiber Reinforced Polymer (CFRP)

CFRP is a composite material that offers exceptional stiffness and strength while being extremely lightweight. It is commonly used in high - performance and luxury vehicles, such as in the body shells and chassis components. For example, some supercars use CFRP extensively to reduce weight and improve performance. Although the production cost of CFRP is high, continuous advancements in manufacturing technology are gradually making it more accessible for mainstream vehicle production.

3.4 Advanced High - Strength Steel (AHSS)

AHSS combines high strength with relatively low weight. It is used in safety - critical areas of the vehicle, such as the frame and crash structures. AHSS allows manufacturers to reduce the thickness of steel components without sacrificing strength, thereby reducing weight. This material is also cost - effective compared to some other lightweight alternatives and is widely available, making it a popular choice for many automakers.

4. Applications of Lightweight Components in Different Automotive Parts

4.1 Body Structure

The body structure of a vehicle is a prime area for lightweighting. By using materials like aluminum, CFRP, and AHSS, automakers can significantly reduce the body weight. For example, some luxury car manufacturers use aluminum body frames, which are not only lighter but also offer good corrosion resistance. In addition, the use of composite materials in body panels can further reduce weight while maintaining the required strength and stiffness. A lighter body structure not only improves fuel efficiency but also enhances the vehicle's handling and performance.

4.2 Powertrain Components

Lightweighting in powertrain components is crucial for improving the overall efficiency of the vehicle. Aluminum is commonly used in engine blocks, cylinder heads, and transmission cases. For instance, an aluminum engine block can be up to 30 - 40% lighter than a cast - iron one. This reduction in weight not only helps in improving fuel efficiency but also reduces the load on the engine, resulting in lower wear and tear. In addition, the use of lightweight materials in components like flywheels and crankshafts can improve the engine's responsiveness and performance.

4.3 Interior Components

Interior components also offer opportunities for lightweighting. Materials such as magnesium and lightweight plastics are used in the production of seats, instrument panels, and door trims. For example, magnesium seat frames are lighter than traditional steel frames, reducing the overall weight of the vehicle. Lightweight plastics can be used to create complex interior components with the same or better functionality as their heavier counterparts. This not only contributes to weight reduction but also allows for more creative design options.

4.4 Suspension and Brake Systems

In suspension systems, lightweight components can improve the vehicle's ride quality and handling. Aluminum and magnesium are used in suspension arms and components, reducing unsprung weight. A lower unsprung weight allows the wheels to better follow the road surface, resulting in improved traction and handling. In brake systems, lightweight materials can be used in brake calipers and rotors. For example, some high - performance brake calipers are made from lightweight alloys, reducing the weight of the braking system and improving its performance.

5. Challenges in the Adoption of Lightweight Auto Components

5.1 Cost

One of the major challenges in the widespread adoption of lightweight auto components is the cost. Materials like carbon fiber and magnesium are relatively expensive compared to traditional materials such as steel. The high cost of these materials is due to factors such as complex manufacturing processes and limited availability. In addition, the production of lightweight components often requires specialized equipment and skilled labor, further increasing the cost. This cost factor can make vehicles with lightweight components more expensive for consumers, potentially affecting their market acceptance.

5.2 Manufacturing Complexity

Lightweight materials often present challenges in the manufacturing process. For example, carbon fiber composites require precise manufacturing techniques to ensure proper fiber orientation and adhesion, which can be difficult to achieve on a large scale. Welding and joining lightweight materials can also be more complex compared to traditional metals. Different materials may have different melting points, thermal expansion coefficients, and mechanical properties, making it challenging to create strong and reliable joints. This manufacturing complexity can increase production time and cost and may require significant investment in research and development to overcome.

5.3 Recyclability

Although lightweight materials offer many benefits, their recyclability can be a concern. Some composite materials, such as CFRP, are difficult to recycle, and the recycling process may not be as efficient as that of traditional materials like steel and aluminum. As environmental sustainability becomes an increasingly important factor in the automotive industry, finding solutions for the recyclability of lightweight materials is crucial. Automakers need to develop recycling processes that are both economically viable and environmentally friendly to ensure the long - term sustainability of lightweight auto components.

6. Future Outlook

The future of lightweight auto components looks promising. As technology continues to advance, new lightweight materials are being developed, and existing materials are becoming more cost - effective. For example, research is being conducted on the development of new composite materials with improved properties and lower production costs. In addition, advancements in manufacturing technology, such as 3D printing and automated manufacturing processes, are expected to reduce the complexity and cost of producing lightweight components.

Moreover, with the increasing demand for electric vehicles, lightweighting will become even more critical. Electric vehicles rely on batteries for power, and reducing the vehicle weight can significantly increase the battery range. As a result, automakers are likely to invest more in lightweight auto components to meet the growing demand for electric vehicles with longer ranges.

In conclusion, lightweight auto components are revolutionizing the automotive industry by offering numerous benefits in terms of fuel efficiency, performance, and safety. Although there are challenges to overcome, the future outlook for lightweight auto components is bright, and they are expected to play an increasingly important role in the development of more sustainable and high - performance vehicles.

| Type | Automotive Aluminum Parts | Entrance size | Customized at your need |

Get the latest prices? We will respond as soon as possible (within 12 hours)