Aluminum Extrusion Manufacturing

A Guide to Selecting Aluminum Alloys for Extrusion Projects

- Customized

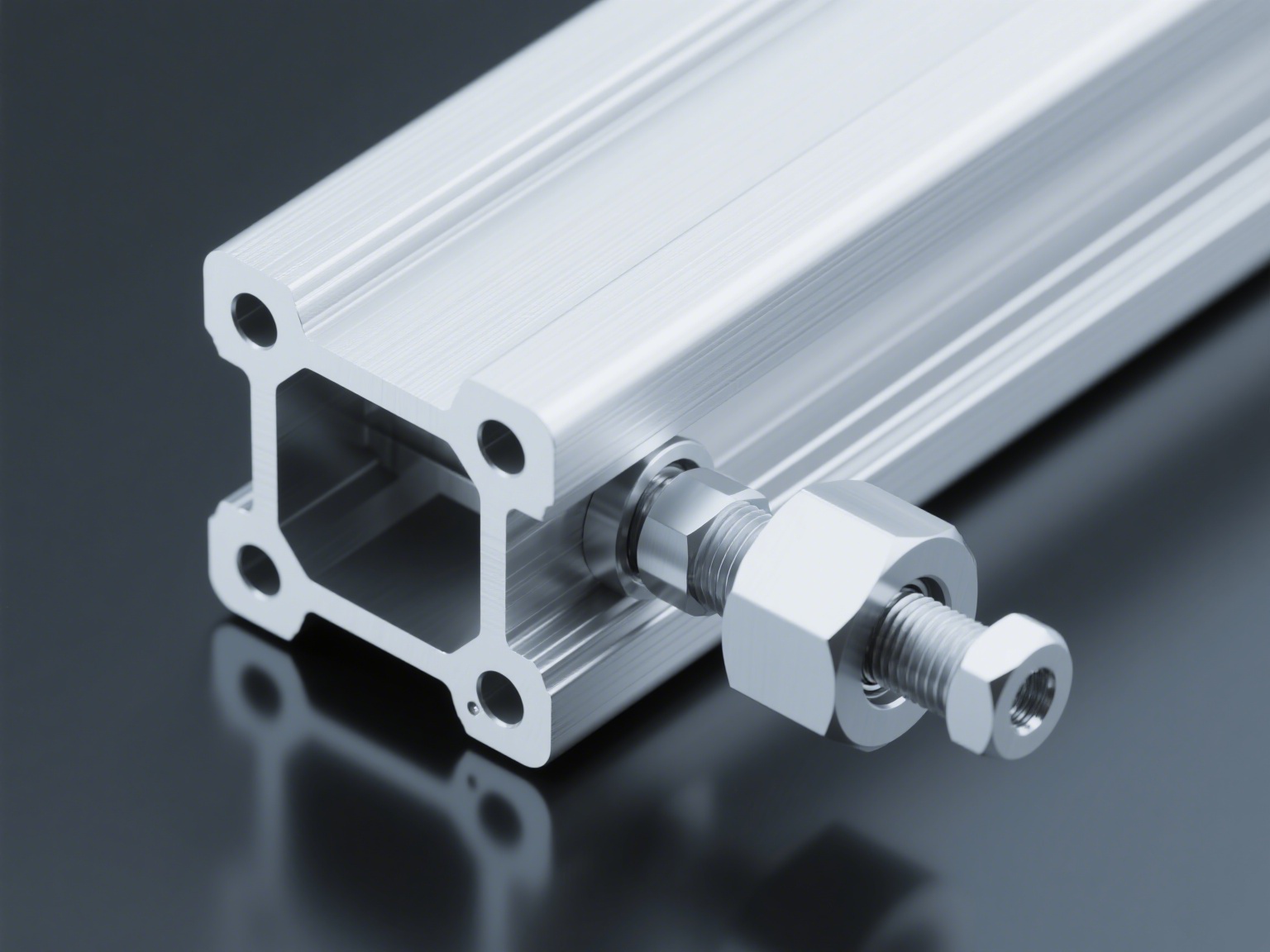

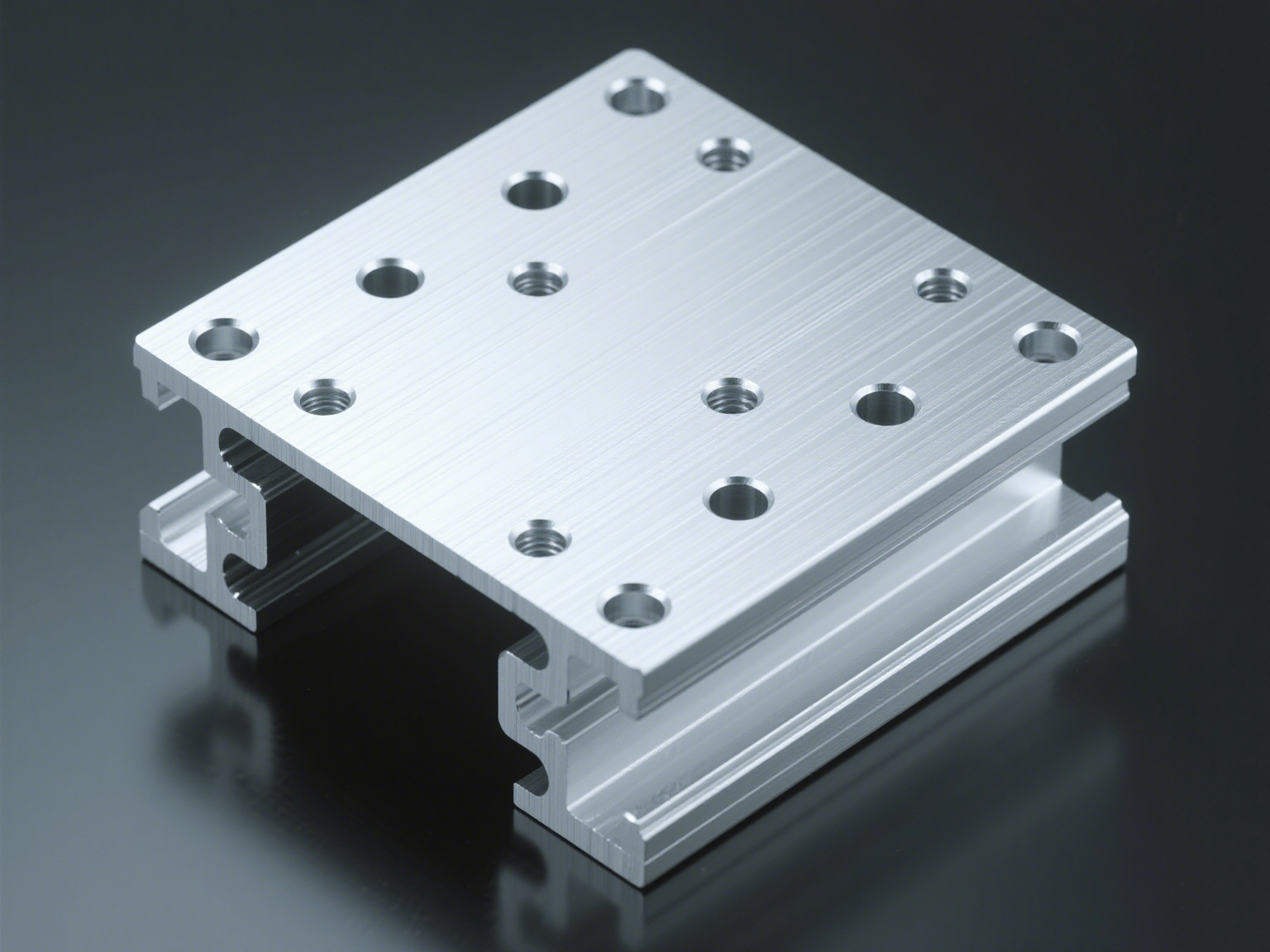

- Aluminum Extrusion

- Customized

- Informations

- Description

A Guide to Selecting Aluminum Alloys for Extrusion Projects

A Guide to Selecting Aluminum Alloys for Extrusion Projects

1. Understanding Alloy Series for Extrusion

6xxx Series (Mg & Si): E.g., 6061, 6063. Known for high extrudability and good corrosion resistance.

2xxx Series (Cu): E.g., 2024. High strength but lower extrudability, used in aerospace.

7xxx Series (Zn): E.g., 7075. Ultra-high strength, suitable for structural components in automotive and defense.

2. Key Factors in Alloy Selection

Mechanical Requirements: Tensile strength, yield strength, and ductility vary by alloy. For example, 6061-T6 offers higher strength than 6063-T5, making it preferable for load-bearing structures.

Extrudability: Alloys like 6063 are easier to extrude into complex shapes, while high-strength alloys like 7075 require more robust extrusion equipment.

Corrosion Resistance: Marine or outdoor applications benefit from 6063 or 5xxx series (Al-Mg) alloys, which resist saltwater and atmospheric corrosion.

Heat Treatment: Some alloys (e.g., 6061, 2024) can be heat-treated to enhance strength, while others (e.g., 5xxx series) rely on work hardening.

3. Popular Aluminum Alloys for Extrusion and Their Applications

Alloy | Temper | Primary Properties | Typical Applications |

6063 | T5/T6 | Good extrudability, moderate strength, excellent surface finish for anodizing. | Window frames, architectural trim, decorative profiles. |

6061 | T6/T651 | Higher strength than 6063, good corrosion resistance, weldability. | Industrial frames, automotive parts, bicycle frames. |

6005A | T6 | Medium strength, good formability, ideal for structural applications. | Trusses, beams, furniture components. |

7075 | T6/T651 | Ultra-high strength, excellent fatigue resistance, but lower extrudability. | Aircraft components, high-performance machinery parts. |

5052 | H32 | Good corrosion resistance (especially to saltwater), moderate strength. | Marine hardware, chemical equipment, fuel tanks. |

2024 | T3/T4 | High strength, good fatigue resistance, but limited corrosion resistance. | Aircraft skins, wing components, high-stress mechanical parts. |

4. Alloy Selection Case Study: Automotive vs. Architectural Applications

Automotive: A manufacturer designing lightweight chassis components might choose 6061-T6 for its high strength and impact resistance, while ensuring the alloy can be extruded into complex shapes for crash absorption.

Architecture: For curtain wall systems, 6063-T5 is preferred for its ease of extrusion into slim profiles, combined with anodizing compatibility for aesthetic and protective finishes.

5. Collaborating with Extrusion Experts

Conclusion

| Type | Aluminum Extrusion | Entrance size | Customized |