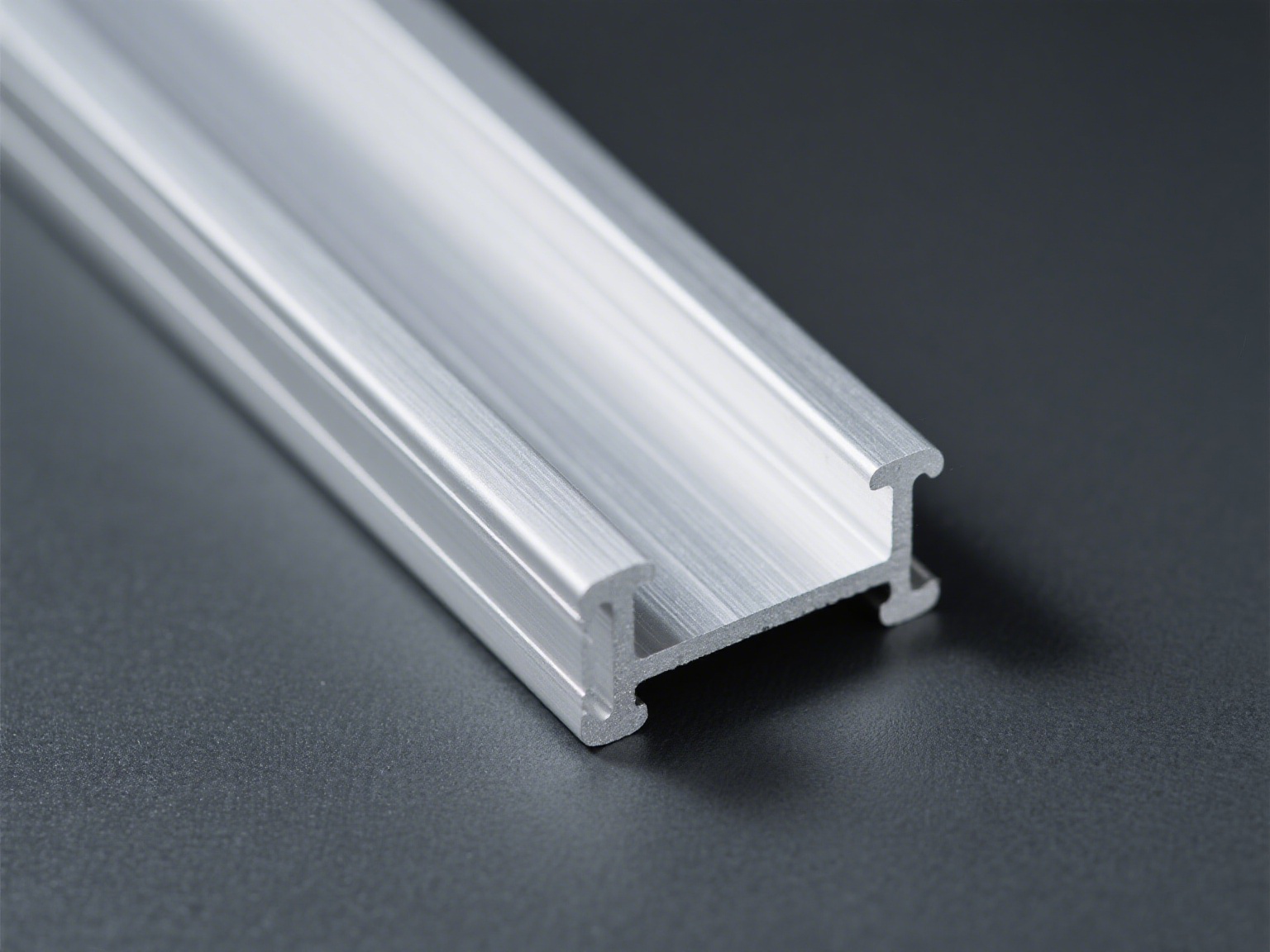

Custom Aluminum Extrusion Services

The Advantages of Aluminum Extrusion Technology in Modern Manufacturing

- Customized

- Aluminum Extrusion

- Customized

- Informations

- Description

The Advantages of Aluminum Extrusion Technology in Modern Manufacturing

The Advantages of Aluminum Extrusion Technology in Modern Manufacturing

Aluminum extrusion has emerged as a cornerstone of modern manufacturing, celebrated for its versatility, efficiency, and cost-effectiveness. This process involves forcing aluminum alloy through a die to create complex, uniform profiles, making it ideal for diverse industries—from architecture to aerospace. Below are the core advantages that position aluminum extrusion as a preferred manufacturing method:

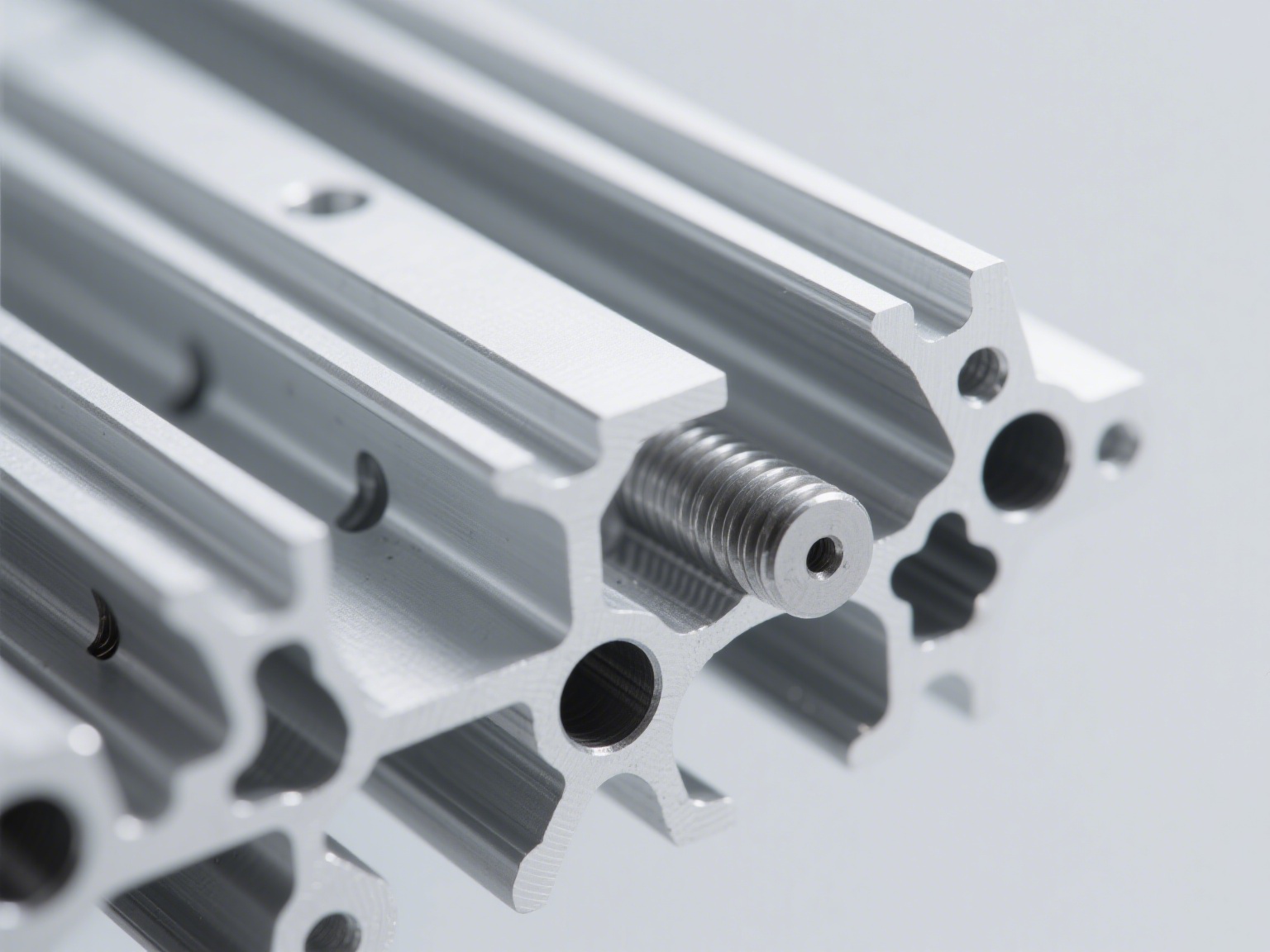

1. Exceptional Design Flexibility

Aluminum extrusion allows for the creation of intricate cross-sections that would be impossible with traditional machining. Designers can integrate features like hollow cavities, slots, and ribs directly into the profile, reducing assembly steps. For example, architectural extrusions often include built-in channels for wiring or weatherstripping, streamlining installation in construction projects.

2. High Strength-to-Weight Ratio

Aluminum alloys used in extrusion, such as 6063 and 6061, offer remarkable strength while remaining lightweight. This makes extruded aluminum profiles perfect for applications where weight reduction is critical, such as automotive components or aircraft frames. Compared to steel, aluminum extrusions can reduce part weight by up to 60% without compromising structural integrity.

3. Corrosion Resistance and Durability

Aluminum naturally forms a protective oxide layer, making extruded products highly resistant to corrosion. This property is especially valuable in outdoor applications, such as window frames, marine components, and infrastructure. Anodizing or powder coating can further enhance durability, extending the lifespan of extrusions in harsh environments.

4. Cost-Effective Production at Scale

While die creation requires an initial investment, aluminum extrusion is highly cost-effective for mass production. The process minimizes material waste (up to 95% material utilization) and reduces the need for secondary machining. Additionally, extruded profiles can be cut to precise lengths with minimal post-processing, lowering labor and production costs.

5. Energy Efficiency and Sustainability

Aluminum is one of the most recyclable materials, with over 75% of all aluminum ever produced still in use today. Extrusion processes consume less energy compared to casting or forging, and recycled aluminum can be used without compromising quality. This sustainability aligns with global trends toward eco-friendly manufacturing.

Table: Comparative Advantages of Aluminum Extrusion vs. Other Manufacturing Methods

Criteria | Aluminum Extrusion | Casting | Machining |

Design Complexity | High (intricate profiles possible) | Medium (limited by mold design) | Low (material removal limits complexity) |

Material Waste | Minimal (90-95% utilization) | Moderate (mold scrap) | High (chipping and cutting waste) |

Production Speed | Fast (continuous extrusion) | Medium (cycle time dependent on mold) | Slow (step-by-step machining) |

Cost for Large Batches | Low (economies of scale) | Medium (mold costs remain high) | High (labor and machine time) |

Surface Finish | Smooth (requires minimal finishing) | Varies (depends on mold quality) | High (depends on machining precision) |

Aluminum extrusion combines design flexibility, mechanical performance, and cost-efficiency, making it an indispensable technology for modern manufacturers. By leveraging its advantages, industries can produce innovative, durable products while minimizing environmental impact.

| Type | Aluminum Extrusion | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)