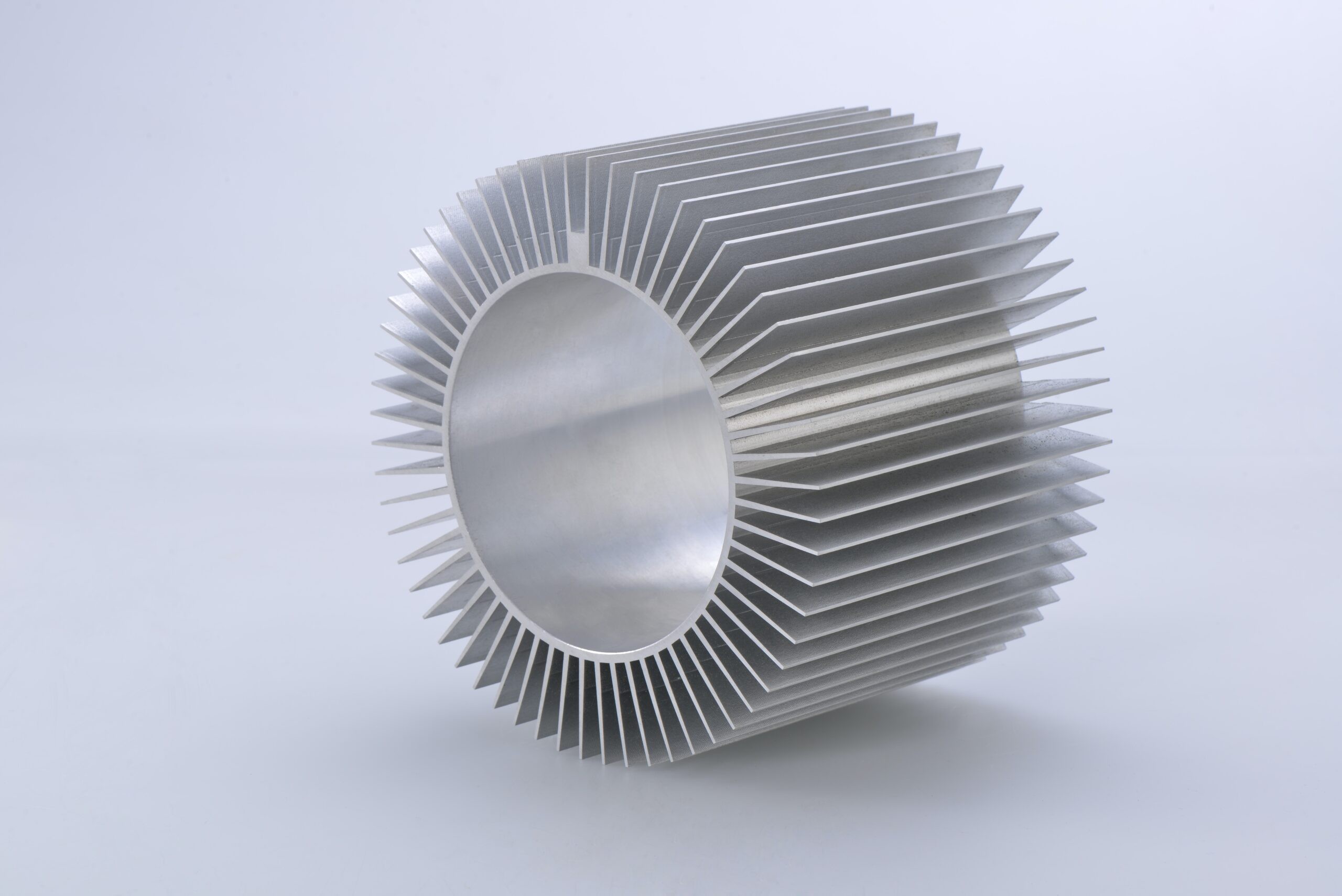

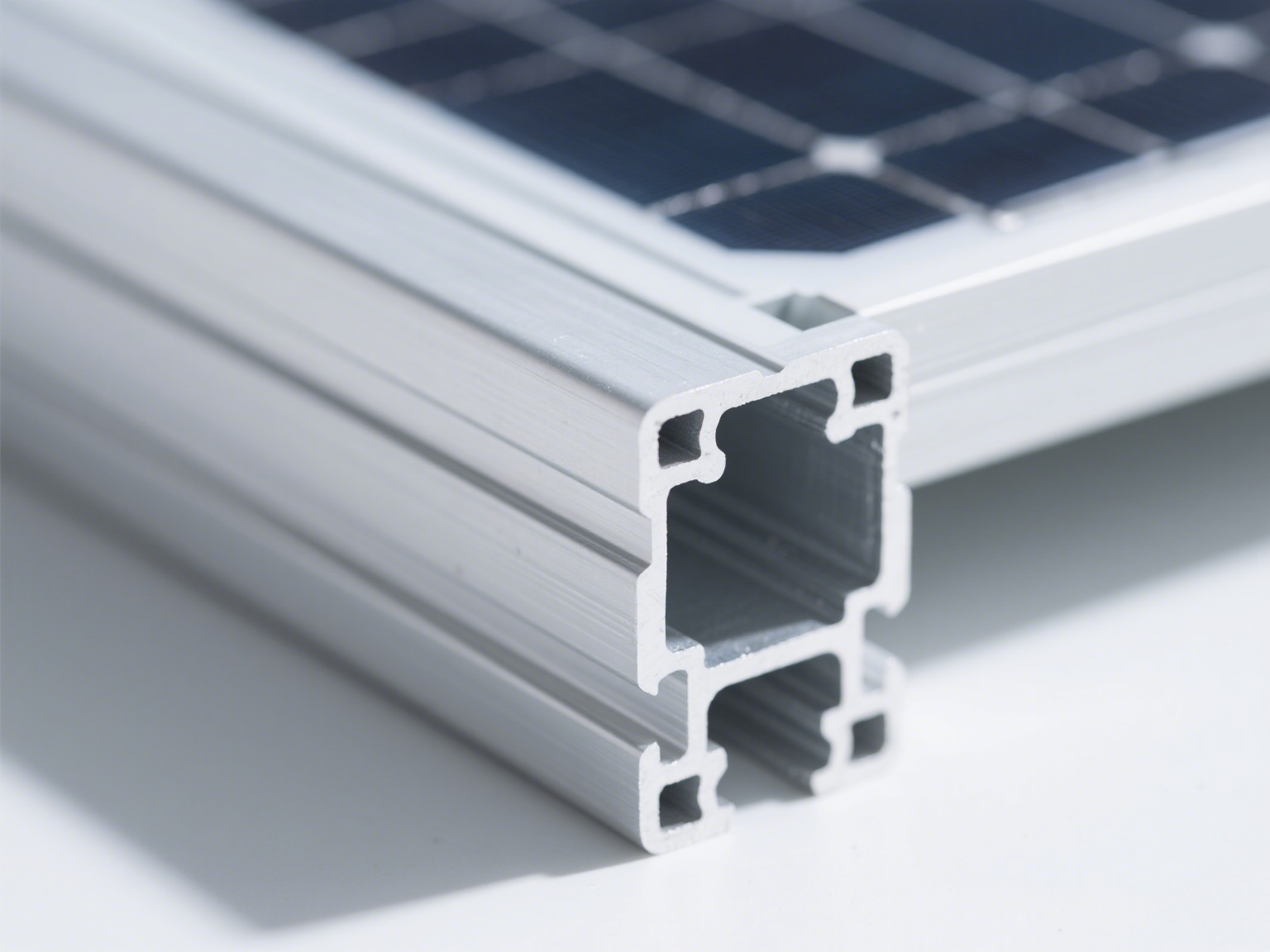

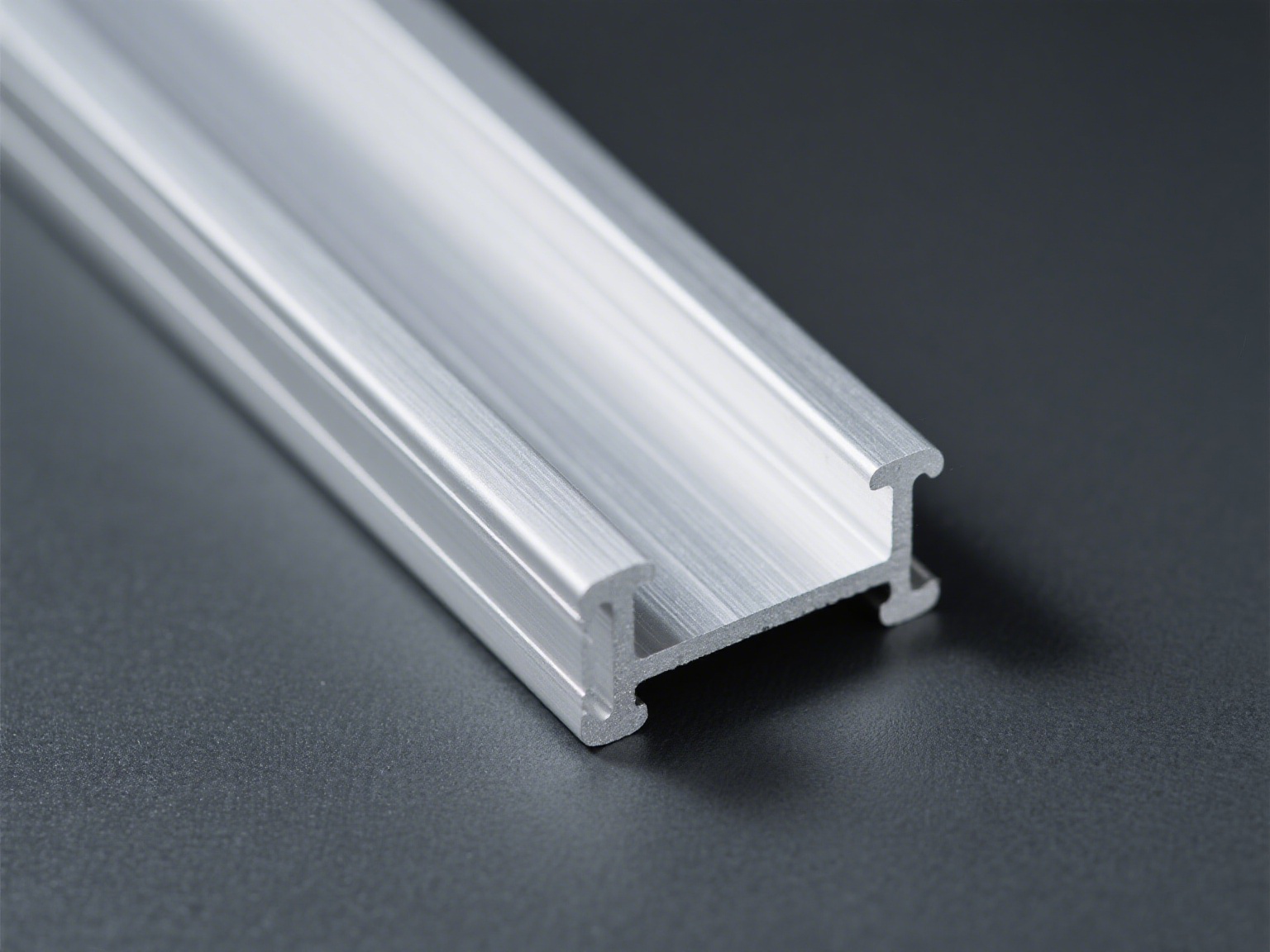

Aluminum Parts Extrusion Process

Unveiling the Wonders of Aluminum Parts Extrusion Process

- Customized

- Aluminum Extrusion

- Customized

- Informations

- Description

Unveiling the Wonders of Aluminum Parts Extrusion Process

Die Preparation: The journey begins with the creation or selection of an appropriate extrusion die. Made from high-strength materials such as H13 steel, the die is preheated to a temperature range of 450 - 500 degrees Celsius. This preheating is crucial as it not only maximizes the die's lifespan but also ensures smooth and even metal flow during the extrusion process.

Billet Preheating: A solid, cylindrical aluminum billet is cut from a larger log of alloy material. It is then preheated in an oven to a temperature between 400 - 500 degrees Celsius. This heating makes the billet malleable enough to be extruded but not molten, ensuring optimal working conditions.

Transfer to the Extrusion Press: Once preheated, the billet is carefully transferred to the extrusion press. Before loading, a lubricant or release agent is applied to both the billet and the extrusion ram. This preventive measure stops the billet and ram from sticking together during the high-pressure extrusion process.

The Extrusion Action: Inside the extrusion press, a hydraulic ram exerts an enormous amount of pressure, up to 15,000 tons in some cases, on the malleable billet. As the pressure is applied, the billet material is pushed into the container of the extrusion press, expanding to fill the walls. The aluminum then has no option but to flow through the die opening, emerging in the shape defined by the die.

Guiding and Quenching: Immediately after emerging from the die, the extrusion is gripped by a puller. This puller guides the extrusion along the runout table at a speed that matches its exit from the press. As it moves along the table, the profile is quenched, which involves uniform cooling. This can be achieved through a water bath or by fans positioned above the table.

Cutting and Finishing: The extrusion is first sheared to a suitable table length using a hot saw. Although it has been quenched, the extrusion has not fully cooled. After shearing, it is moved to a cooling table until it reaches room temperature. To correct any twists or deformities, the extrusion is then moved to a stretcher where it is pulled until it is straight and in the correct specification. Finally, it is transferred to a finish saw and cut to the pre-specified lengths required for the final product.

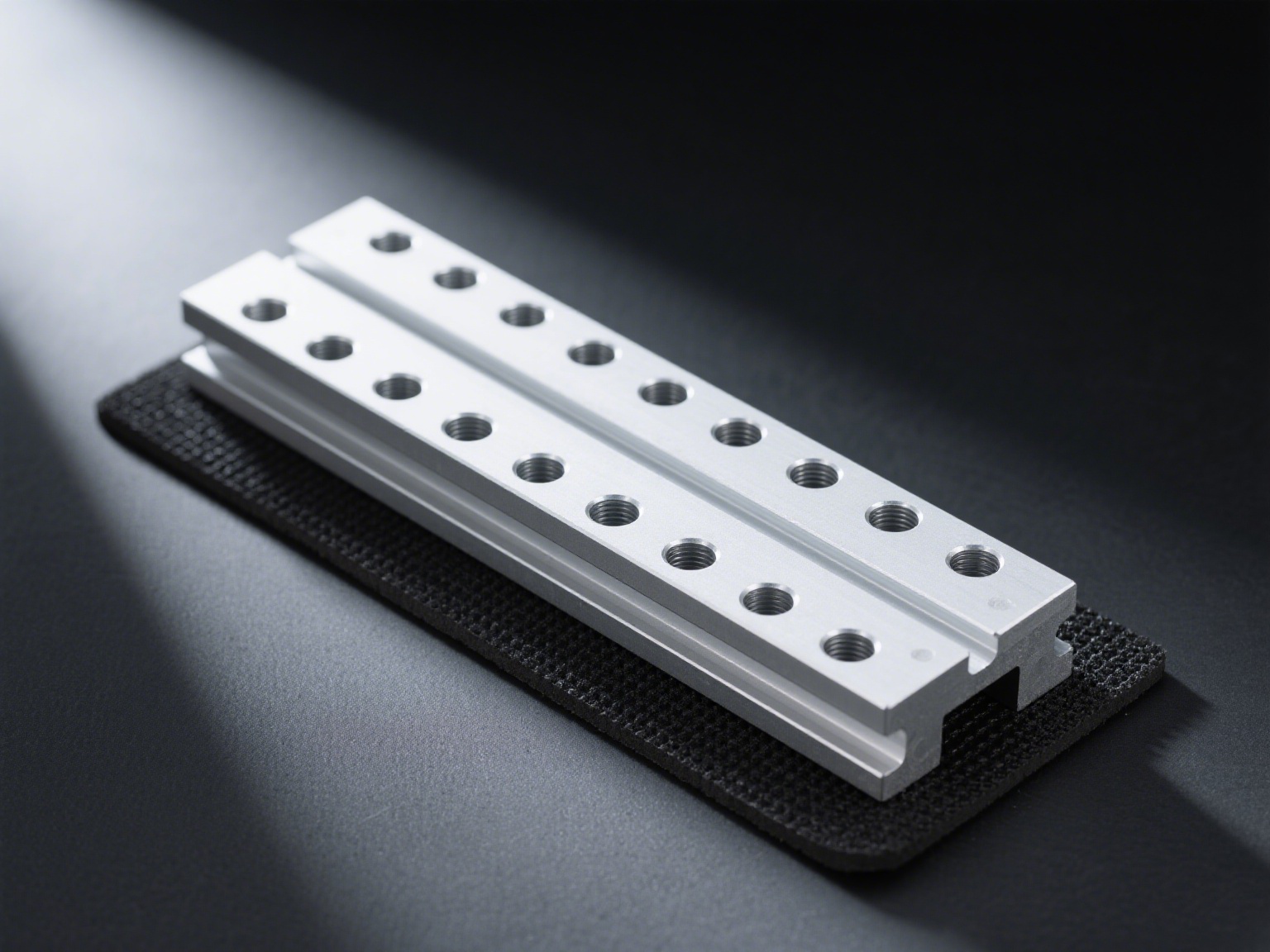

| Type | Aluminum Extrusion | Entrance size | Customized |