Aluminum Extrusion Process

What is Aluminum Extrusion

- Customized

- Aluminum Extrusion

- Customized

- Informations

- Description

What is Aluminum Extrusion

Definition of Aluminum Extrusion

Aluminum extrusion, also known as aluminum extrusion molding, represents a sophisticated plastic processing technique.

In this process, substantial pressure is exerted on an aluminum billet positioned within a mold cavity (or extrusion cylinder).

This force compels the aluminum billet to undergo directional plastic deformation, subsequently extruding it through the die

hole of the extrusion die. As a result, parts or semi - finished products with the desired cross - sectional shape, precise dimensions,

and specific mechanical properties are obtained.

The underlying principle of aluminum extrusion can be analogized to squeezing toothpaste. Under the influence of pressure,

the aluminum ingot is divided into multiple metal flows. These flows enter the welding chamber via the diversion holes, converge

within the chamber, and are re - welded under conditions of high temperature, high pressure, and high vacuum. Finally, the aluminum

material flows out through the gap between the mold core and the die hole, giving rise to tubes or hollow profiles that conform to the

required size and performance specifications. In cases where bending is necessary, a bending tool is integrated into the subsequent equipment.

Application of Aluminum Extrusion

Aluminum extrusion products enjoy extensive applications across diverse sectors, including construction, transportation, electronics, and home

furnishings. Their exceptional performance and characteristics have become a catalyst for innovation and development in various industries.

Specific applications encompass:

Electronics: Heat sinks for electronic products, housings of electronic devices, LED lighting profiles.

Aerospace: Structural components of aircraft.

Home Appliances: Parts for household appliances.

Automotive: Automotive components.

Transportation: Bicycle racks.

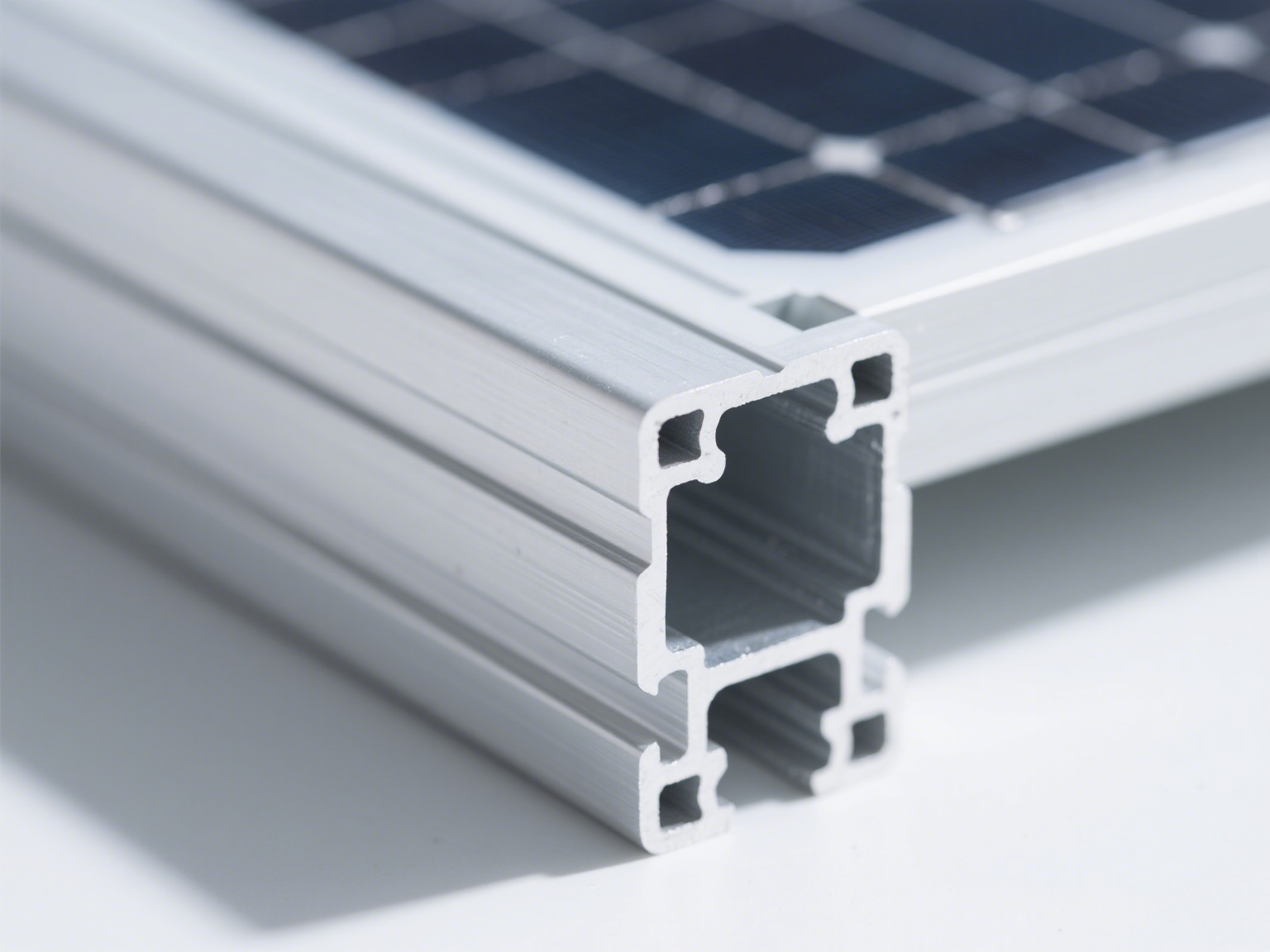

Construction: Window and door frames, solar panel frames.

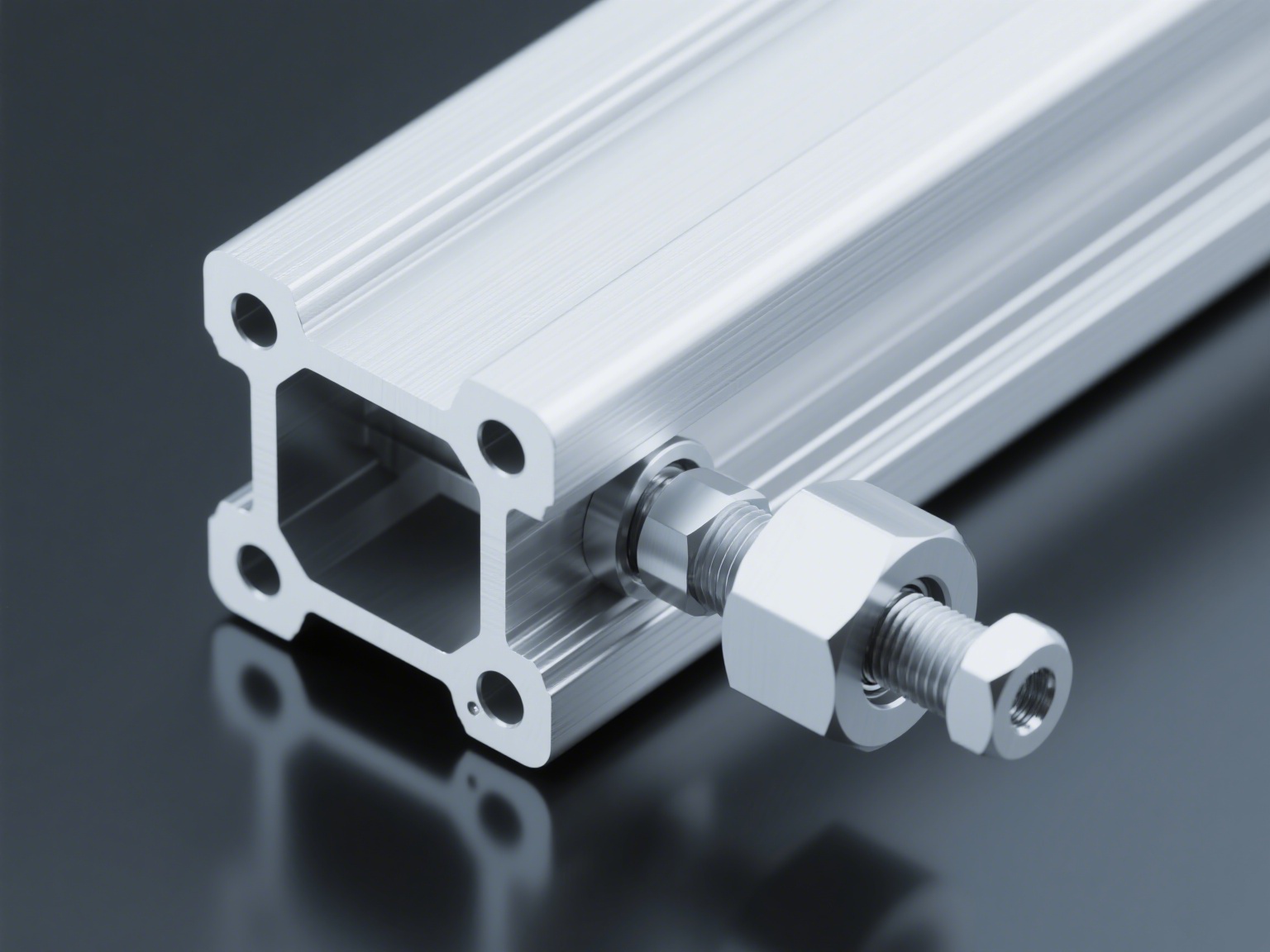

Industrial Equipment: Conveyor structures, components of wind turbines.

Retail and Display: Display racks and retail fixtures.

Advantages of the Aluminum Extrusion Process

1. Durability

One of the most prominent advantages of aluminum is its remarkable corrosion resistance, anti - corrosive properties, and weather resistance.

Aluminum can develop a natural oxide layer that effectively protects it from rust and corrosion, often eliminating the need for additional protective treatments.

2. Lightweight and High - Strength

Aluminum is over 33% lighter than steel while still maintaining a significant portion of its strength. This characteristic makes it an ideal material for applications

where weight reduction is crucial without sacrificing structural integrity.

3. Excellent Thermal Conductivity

Aluminum exhibits thermal conductivity comparable to that of copper, yet it is much lighter. This property makes it highly suitable for applications requiring

efficient heat dissipation, such as in electronics and thermal management systems.

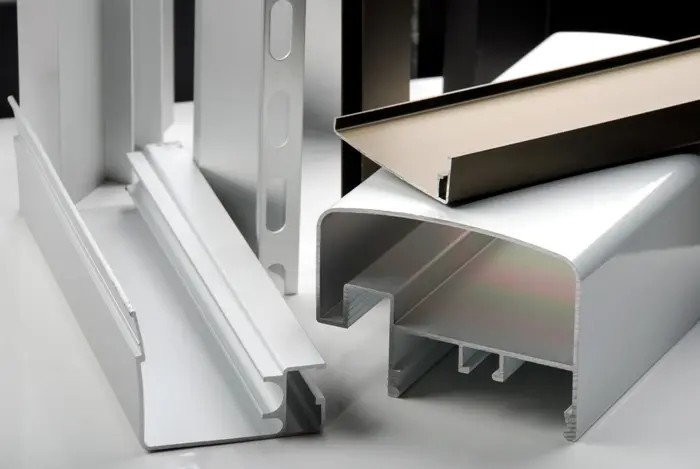

4. Aesthetic Appeal

Extruded aluminum products can undergo various surface treatments, including painting, electroplating, polishing, and anodizing. These treatments offer

engineers a broader spectrum of aesthetic options compared to many other materials, enabling the creation of products with enhanced visual appeal.

5. Versatile Applications

Aluminum extrusion can be used to form virtually any cross - sectional shape. This versatility allows for a wide range of applications, as engineers can design

custom cross - sections to meet the specific requirements of different application environments.

6. Ease of Secondary Processing

Aluminum extrusions can be easily manipulated through processes such as forming, cutting, drilling, machining, stamping, bending, and welding. These capabilities

enable the customization of extruded products to suit specific functional requirements.

7. Short Mold Processing Cycle and Low Cost

The molds used in aluminum extrusion are relatively simple in design. This simplicity results in a shorter processing cycle and lower production costs, making aluminum

extrusion an economically viable manufacturing option.

8. Shock and Deformation Absorption

In the construction industry, aluminum extrusions play a crucial role in resisting deformation caused by weather conditions and building movements. Their ability to absorb

shock and withstand deformation contributes to the overall structural stability and durability of buildings.

9. Environmental Friendliness

Aluminum is an environmentally friendly material due to its high recyclability. Recycling aluminum requires significantly less energy compared to primary production, reducing

the environmental impact associated with its use and disposal.

| Type | Aluminum Extrusion | Entrance size | Customized |