Aluminum Polishing: A Comprehensive Guide

In the world of aluminum products manufacturing, aluminum polishing stands out as a crucial process that can transform the look and performance of aluminum items. At Shanfeng, a professional aluminum products processing factory, we have mastered this technique to offer high - quality aluminum products to our customers.

The Aluminum Polishing Process

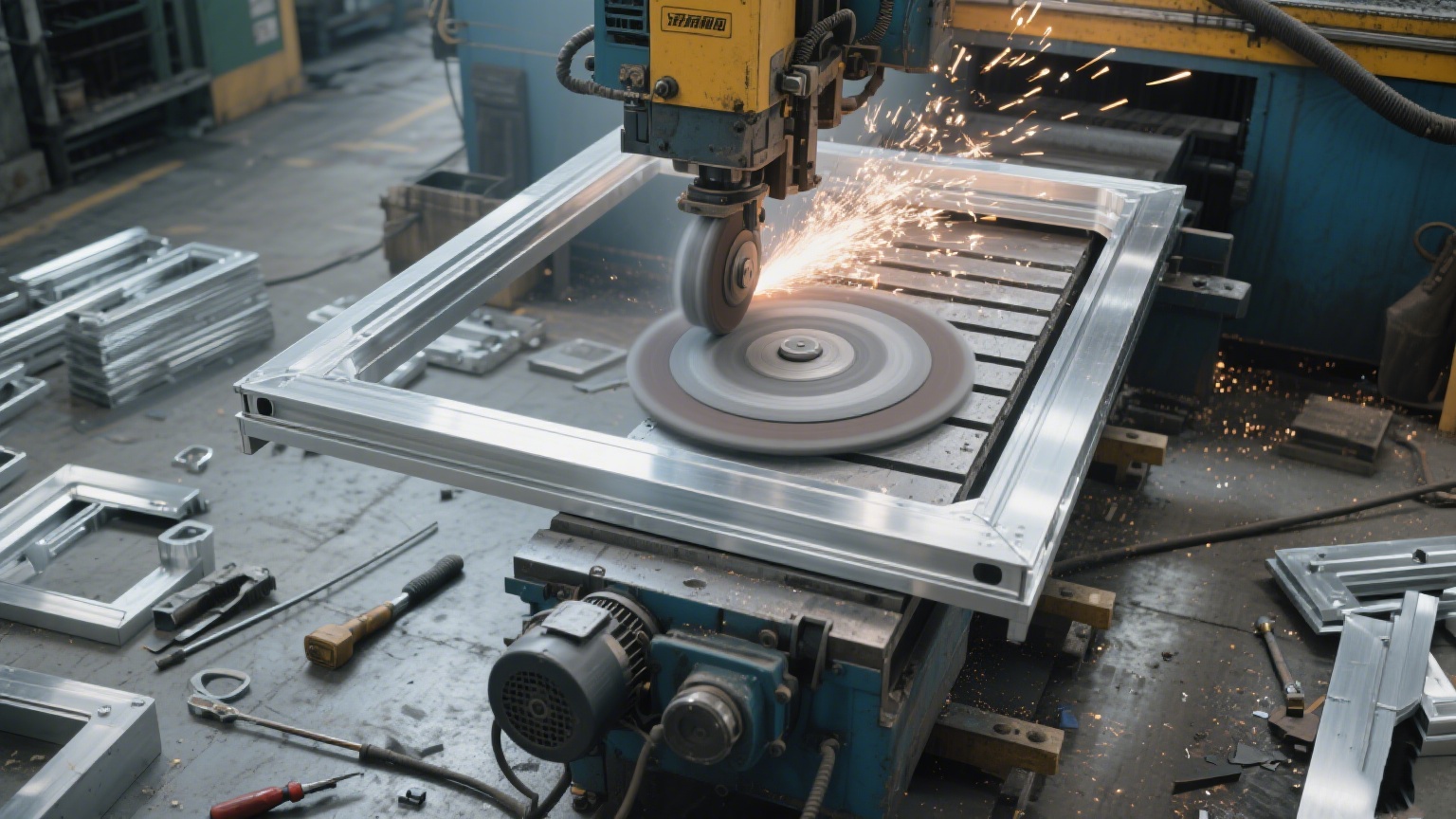

Mechanical Polishing

Mechanical polishing is one of the most commonly used methods. It involves using a high - speed rotating polishing wheel. The wheel is usually made of materials like cotton, sisal, or felt, and is used in conjunction with polishing compounds. When the wheel rotates at high speed against the aluminum surface, the friction between them generates heat. This heat causes the metal surface to undergo plastic deformation, gradually flattening the convex and concave points on the surface.

For example, in the production of aluminum automotive parts, mechanical polishing can be used to remove surface burrs, scratches, and other imperfections. According to industry data, a well - executed mechanical polishing process can reduce the surface roughness of aluminum from an average of 10 - 15 micrometers to 1 - 3 micrometers, significantly improving the surface smoothness.

Electropolishing

Electropolishing, also known as electrochemical polishing, is a more advanced method. In this process, the aluminum workpiece is placed in an electrolytic cell containing a special polishing electrolyte. When an electric current is applied, a passivation film forms on the aluminum alloy surface. Due to the difference in current density between the convex and non - convex parts of the aluminum alloy surface, the convex parts dissolve at a faster rate. This results in a leveling effect on the surface.

The traditional electrochemical polishing solution for aluminum often contains phosphoric acid, sulfuric acid, and chromic acid. However, due to environmental concerns, in recent years, new electrolytic polishing solutions without chromic acid have been developed. This not only reduces environmental pollution but also provides a cleaner and more efficient polishing option.

Chemical Polishing

Chemical polishing is a surface treatment method that relies on the chemical solvent's ability to dissolve the convex part of the aluminum alloy surface at a faster rate than the concave part. This method is especially suitable for achieving bright and mirror - like surfaces on aluminum products. The chemical reaction between the solvent and the aluminum surface can effectively remove surface impurities and micro - roughness, giving the aluminum a smooth and shiny finish.

Advantages of Aluminum Polishing

Aesthetic Appeal

One of the most obvious advantages of aluminum polishing is its ability to enhance the aesthetic appeal. A polished aluminum surface has a high - reflectivity, sleek appearance that can add a touch of luxury and modernity. In the automotive industry, polished aluminum wheels and grilles can make a vehicle look more stylish and high - end. In architecture, polished aluminum handrails and decorative accents can create a visually stunning effect.

Corrosion Resistance

Although aluminum has some natural corrosion - resistance due to the formation of a thin oxide layer on its surface, polishing can further enhance this property. By removing surface imperfections where rust or oxidation could potentially start, polished aluminum is more resistant to environmental factors. A study showed that polished aluminum samples had a corrosion rate 30 - 40% lower than non - polished samples when exposed to the same corrosive environment for a year.

Light Reflection

Polished aluminum has excellent light - reflection properties. This makes it valuable in applications where light redirection or reflection is required, such as in lighting fixtures, mirrors, and precision optics. For example, in LED lighting fixtures, polished aluminum reflectors can improve the light - output efficiency by 15 - 20%, making the lighting more energy - efficient.

Easy Maintenance

The smooth surface of polished aluminum makes it less likely to accumulate dirt, grime, or other contaminants. Cleaning polished aluminum products is relatively easy, usually only requiring a mild cleaner and a soft cloth. This low - maintenance characteristic is highly desirable in applications such as kitchen appliances, where the surface needs to be kept clean regularly.

Application Industries

Automotive Industry

In the automotive industry, aluminum polishing is widely used. Polished aluminum is used for wheels, grilles, trim, and engine components. It not only improves the appearance of the vehicle but also enhances its corrosion resistance, which is crucial for parts that are constantly exposed to various environmental conditions.

Aerospace and Aviation

The aerospace and aviation sectors also rely on aluminum polishing. Polished aluminum is used for aircraft exteriors, interior fixtures, and engine components. The smooth surface of polished aluminum can reduce air resistance, improving the fuel efficiency of aircraft. Additionally, its corrosion - resistance is essential for parts that need to withstand harsh atmospheric conditions during flights.

Architecture and Interior Design

In architecture and interior design, polished aluminum is used for a variety of elements, including handrails, facades, and decorative accents. Its reflective quality can create an illusion of more space in interior design, while its durability and weather - resistance make it suitable for exterior applications.

Consumer Electronics

Many consumer electronics, such as smartphones, laptops, and audio equipment, feature polished aluminum casings. The polished finish gives these devices a premium look and feel. Moreover, aluminum's good heat - dissipation properties, combined with the smooth surface from polishing, help in better heat transfer, ensuring the proper functioning of the electronic components inside.

Jewelry and Accessories

Polished aluminum is also used in the creation of fashion jewelry, watches, and accessories. Its lightweight nature, corrosion resistance, and reflective finish make it an attractive alternative to more expensive metals in the jewelry industry.

Aluminum Products Requiring Polishing

Aluminum Alloys with High - Visual Requirements: For example, 6061 - T6 aluminum alloy, which is widely used in the automotive and aerospace industries. After polishing, its surface can meet the high - end aesthetic standards of these industries.

Everyday Items Produced with Aluminum Polishing

Kitchenware: Aluminum pots, pans, and utensils are often polished. A polished surface not only looks good but also makes it easier to clean food residues, preventing them from sticking to the surface.

Home Decor Items: Decorative vases, picture frames, and lamp stands made of aluminum are usually polished to add a touch of elegance to the home decor.

Furniture: Aluminum furniture, such as chairs and tables, may have polished parts. The polished finish can enhance the modern and stylish look of the furniture, while also providing corrosion resistance for long - term use.

In conclusion, aluminum polishing is a versatile and important process that plays a significant role in various industries. At Shanfeng, we are committed to providing high - quality aluminum polishing services to meet the diverse needs of our customers, whether in industrial applications or in the production of everyday consumer goods.

|

Type

|

Aluminum Polishing |

Entrance size

|

Customized at your need |

![]()