Mastering Aluminum Polishing

Mastering Aluminum Polishing

- Customized at your needs

- Aluminum Polishing

- Customized at your needs

- Informations

- Description

Mastering Aluminum Polishing

Mastering Aluminum Polishing: Pioneering Excellence in Every Shine

The Alchemy of Aluminum Polishing

Signature Attributes of Our Aluminum Polishing

Feature | Elaborate Description |

Nano-level Precision | Our advanced computerized polishing systems are engineered to achieve tolerances as minute as nanometers. Whether crafting components for high-precision medical devices or sleek consumer electronics, we ensure that every surface adheres to the strictest specifications with unwavering accuracy. |

Batch Consistency | We've implemented a comprehensive quality control ecosystem that spans the entire polishing process. From automated sensors that monitor every stage to rigorous manual inspections by our seasoned technicians, we guarantee that each batch of products maintains the same superior quality, time and time again. |

Bespoke Finish Options | Recognizing that each project is unique, we offer an expansive array of polishing finishes. From the understated elegance of a brushed satin finish to the mirror-like luster of a diamond-cut high-gloss, we work closely with our clients to bring their design concepts to life with precision and creativity. |

Enhanced Material Resilience | Our polishing process doesn't merely enhance aesthetics—it fortifies the material at its core. By creating a seamless, smooth surface, we boost the aluminum's resistance to corrosion, abrasion, and environmental wear, extending the lifespan of the products and ensuring they maintain their pristine appearance over extended use. |

Outstanding Benefits of Our Aluminum Polishing

Visual Appeal Redefined: In a market where first impressions matter, our polished aluminum products command attention. Whether it’s a high-performance sports car’s trim, a modern architectural facade, or a trendy kitchen appliance, our polishing services add a touch of sophistication and luxury that sets products apart from the competition.

Optimized Operational Efficiency: The ultra-smooth surfaces achieved through our polishing reduce friction in moving parts, such as automotive engines or industrial machinery. This leads to lower energy consumption, reduced wear and tear, and enhanced overall performance, translating into significant cost savings for our clients in the long run.

Market Value Surge: Quality and appearance are key drivers of product value. Our polished aluminum products not only fetch premium prices in the market but also enjoy increased brand loyalty and customer satisfaction, giving our clients a competitive edge in a crowded marketplace.

Industry-wide Adaptability: From the demanding requirements of the aerospace and defense sectors to the mass-production needs of consumer goods manufacturers, our aluminum polishing services are highly adaptable. We've successfully catered to a diverse range of industries, delivering customized solutions that meet the unique challenges and expectations of each.

Critical Factors in Aluminum Polishing

Material Sourcing and Selection: The journey to a flawless finish begins with the right material. We source only the highest-grade aluminum alloys from trusted suppliers, carefully evaluating their composition, purity, and mechanical properties to ensure they’re perfectly suited for the polishing process and the intended application.

Pre-polishing Surface Treatment: A thorough pre-polishing treatment is essential for a successful outcome. Our multi-step cleaning and surface preparation process involves degreasing, deoxidizing, and precision grinding to remove all contaminants and prepare the surface for polishing. Any existing surface defects are expertly repaired to create a uniform base for the polishing process.

Tailored Technique Implementation: Different aluminum products and applications call for different polishing techniques. Our team of experts analyzes each project in detail, considering factors such as part geometry, surface finish requirements, and production volume, to select the most appropriate technique. Whether it's mechanical polishing, chemical polishing, or electrochemical polishing, we have the expertise and equipment to deliver outstanding results.

Controlled Process Environment: The polishing environment plays a crucial role in determining the quality of the final product. Our factory is equipped with climate-controlled workspaces that maintain precise temperature, humidity, and air quality levels. This controlled environment minimizes the risk of contamination and ensures consistent results, even for the most complex and sensitive polishing projects.

Vast Horizons of Application

Automotive Industry: In the automotive world, our polished aluminum parts add both style and performance. From eye-catching alloy wheels and sleek exterior trim to high-performance engine components, our products enhance the vehicle’s aesthetics and functionality, contributing to a superior driving experience.

Aerospace and Defense: The aerospace and defense sectors demand the highest standards of quality and precision. Our polished aluminum components are used in aircraft structures, avionics systems, and military equipment, where lightweight materials, exceptional strength, and corrosion resistance are essential for mission success.

Consumer Electronics: In the fast-paced world of consumer electronics, appearance is just as important as functionality. Our polished aluminum casings and components for smartphones, laptops, tablets, and other devices not only look great but also provide excellent heat dissipation and durability, ensuring optimal performance and a long product lifespan.

Medical and Healthcare: In the medical and healthcare industry, hygiene and precision are paramount. Our polished aluminum parts for medical devices, surgical instruments, and hospital equipment offer a smooth, easy-to-clean surface that meets strict hygiene standards, while also providing the strength and durability required for demanding medical applications.

Architectural and Construction: In architecture and construction, our polished aluminum products add a touch of modern elegance to buildings and structures. From curtain walls and facade cladding to decorative railings and signage, our products enhance the visual appeal of architectural designs, while also providing excellent weather resistance and durability.

Why Partner with Our Factory for Aluminum Polishing?

Decades of Industry Mastery: With years of experience in aluminum product manufacturing and polishing, our team has amassed a wealth of knowledge and expertise. We've successfully completed thousands of projects, from small-scale custom orders to large-volume production runs, earning a reputation for excellence and reliability in the industry.

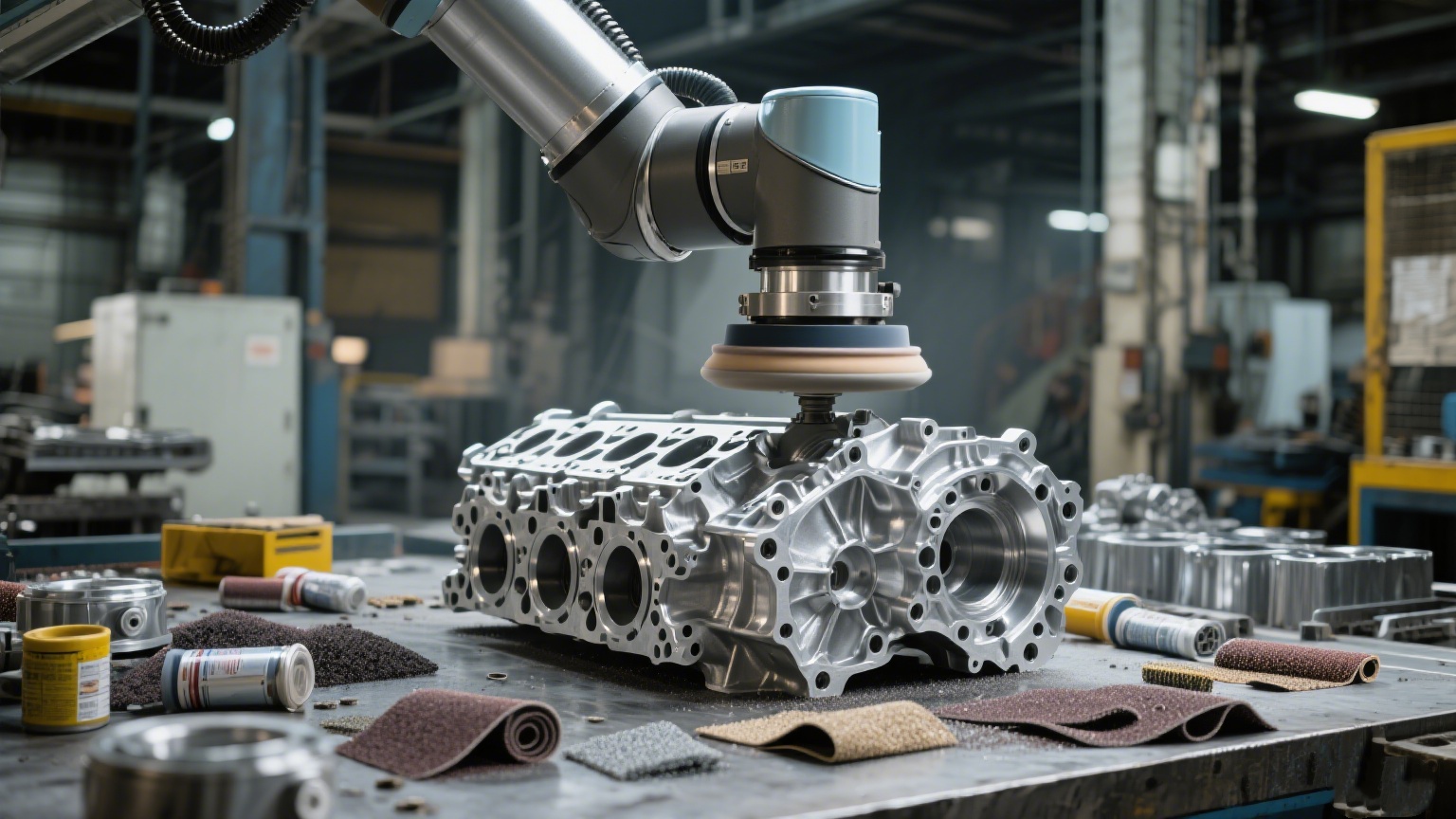

Technological Leadership: We're at the forefront of technological innovation in aluminum polishing. Our factory is equipped with the latest and most advanced polishing equipment, including robotic polishing systems, CNC machining centers, and automated inspection systems. This investment in technology allows us to deliver faster turnaround times, higher precision, and greater productivity, while maintaining the highest quality standards.

Stringent Quality Assurance: Quality is our top priority. We've implemented a comprehensive quality management system that adheres to international standards, ensuring that every product that leaves our factory meets or exceeds our clients' expectations. From raw material inspection to final product testing, we leave no stone unturned in our pursuit of perfection.

Customer-Centric Approach: We believe that our success is measured by the success of our clients. That's why we take a customer-centric approach to everything we do, from initial project consultation to after-sales support. Our dedicated team of customer service representatives, engineers, and technicians work closely with our clients to understand their needs, provide expert advice, and deliver customized solutions that meet their specific requirements.

| Type | Aluminum Polishing | Entrance size | Customized at your needs |