Revolutionize Your Products with Aluminum Plating

Revolutionize Your Products with Aluminum Plating

- Customized at your needs

- Aluminum Electroplating

- Customized at your needs

- Informations

- Description

Revolutionize Your Products with Aluminum Plating

Revolutionize Your Products with Aluminum Plating

Decoding Aluminum Plating

Unrivaled Advantages of Aluminum Plating

Advantage | In-Depth Explanation |

Exceptional Corrosion Protection | Aluminum plating creates a passive oxide film that acts as a shield against moisture, acids, and other corrosive substances. In coastal environments or industries exposed to chemicals, components with aluminum plating can outlast non-plated counterparts by years, reducing the need for frequent replacements and maintenance. |

Enhanced Mechanical Properties | The aluminum coating can increase the hardness and strength of the substrate. For example, in mechanical parts subject to high stress and friction, aluminum plating reduces wear, improving the overall efficiency and extending the service life of the equipment. |

Tailored Aesthetic Appeal | Whether you're aiming for a sleek, mirror-like finish or a textured, matte look, aluminum plating can be customized to meet your exact aesthetic requirements. This makes it perfect for consumer products, where appearance plays a crucial role in attracting customers. |

Cost-Effective Long-Term Solution | Although the initial investment in aluminum plating might seem higher compared to some basic surface treatments, its long-lasting performance and reduced maintenance costs make it a cost-effective choice in the long run. |

Diverse Application Scenarios

Automotive: In the automotive sector, aluminum plating is used on engine components to improve heat dissipation and reduce friction, enhancing fuel efficiency. It's also applied to exterior trim and wheels to give vehicles a luxurious and eye-catching appearance.

Marine: For marine applications, where saltwater corrosion is a constant threat, aluminum plating provides robust protection for ship hulls, propellers, and other critical parts, ensuring the safety and longevity of vessels.

Renewable Energy: In the renewable energy industry, such as wind turbines and solar panel frames, aluminum plating offers excellent corrosion resistance and durability, enabling these structures to withstand harsh environmental conditions and operate efficiently for extended periods.

Art and Design: Artists and designers are increasingly using aluminum plating to add a touch of elegance and modernity to their creations. The ability to customize the finish allows for unique and stunning visual effects.

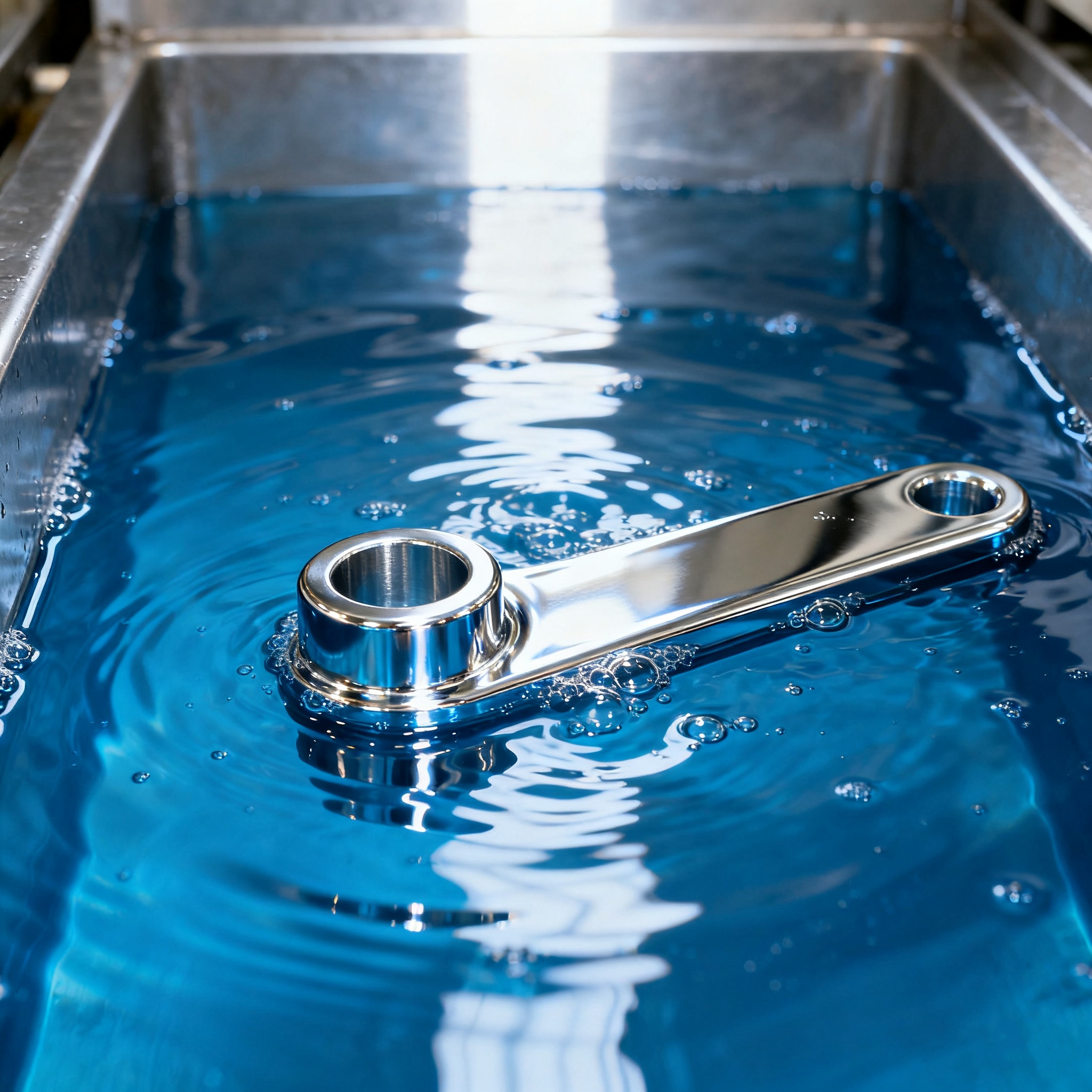

The Art of Aluminum Plating Processing

Electrochemical Plating: This is the most common method. The substrate is immersed in an electrolyte solution containing aluminum ions. When an electric current is passed through the solution, the aluminum ions are deposited onto the substrate, forming a uniform and dense coating.

Chemical Plating: Also known as electroless plating, this method uses chemical reactions to deposit aluminum without the need for an external electric current. It's particularly useful for substrates with complex shapes or those that are non-conductive, as it can coat all surfaces evenly.

Aluminum Plating vs. Anodizing: A Clear Comparison

Aspect | Aluminum Plating | Anodizing |

Coating Formation | Aluminum atoms are deposited onto the substrate from an external source. | An oxide layer is grown on the surface of the aluminum substrate through an electrochemical process within the material itself. |

Thickness Control | Thickness can be precisely controlled, allowing for thin or thick coatings depending on the application. | Thickness is more limited and typically results in a relatively thicker oxide layer. |

Color Options | Offers a wide range of colors through additional coloring processes or by using different alloys in the plating solution. | Color options are more restricted, mainly achieved through dyes or pigments absorbed by the porous oxide layer. |

Surface Hardness | Can achieve high surface hardness, especially when using hardening additives in the plating process. | Hardness varies, and hard anodizing is required to achieve high hardness levels, which is more complex and costly. |

Why Aluminum Plating is the Smart Choice

Performance: It offers superior protection and enhanced properties, ensuring your products can withstand the rigors of their intended use.

Customization: With a wide range of options for finish, color, and thickness, you can tailor the aluminum plating to perfectly match your product's design and functional requirements.

Reliability: Our factory's state-of-the-art equipment and experienced technicians guarantee consistent and high-quality aluminum plating results, giving you peace of mind that your products will meet the highest standards.

| Type | Aluminum Electroplating | Entrance size | Customized at your needs |