Transform Your Metal Products with Innovative Aluminum Plating Solutions

Transform Your Metal Products with Innovative Aluminum Plating Solutions

- Customized at your needs

- Aluminum Electroplating

- Customized at your needs

- Informations

- Description

Transform Your Metal Products with Innovative Aluminum Plating Solutions

Transform Your Metal Products with Innovative Aluminum Plating Solutions

The Science and Art of Aluminum Plating

Key Benefits of Aluminum Plating

Benefit | Explanation |

Enhanced Corrosion Protection | Aluminum plating forms a dense, passive oxide layer that acts as a barrier against moisture, chemicals, and other corrosive agents. This layer provides long-lasting protection, even in harsh environments, ensuring the longevity and reliability of your products. |

Improved Wear Resistance | The aluminum coating increases the hardness and abrasion resistance of the substrate, reducing friction and wear. This is particularly beneficial for components that are subject to high stress, friction, or impact, such as gears, bearings, and cutting tools. |

Superior Aesthetic Appeal | Aluminum plating offers a wide range of finishes, from bright and shiny to matte and textured, allowing you to customize the appearance of your products to meet your specific design requirements. Whether you're looking for a sleek, modern look or a classic, timeless finish, aluminum plating can help you achieve the desired aesthetic. |

Enhanced Electrical and Thermal Conductivity | Aluminum is a highly conductive material, and aluminum plating can improve the electrical and thermal conductivity of the substrate. This makes it ideal for applications where efficient heat dissipation or electrical conductivity is required, such as electronics, automotive, and aerospace. |

Cost-Effective Solution | Despite its many benefits, aluminum plating is a cost-effective surface treatment solution. It can extend the lifespan of your products, reduce maintenance costs, and improve their performance, making it a wise investment for businesses of all sizes. |

Wide Range of Applications

Automotive Industry: In the automotive industry, aluminum plating is used to improve the performance, durability, and aesthetics of components such as engine parts, wheels, trim pieces, and exterior accessories. It can also help to reduce weight, improve fuel efficiency, and enhance the overall safety of the vehicle.

Aerospace Industry: In the aerospace industry, aluminum plating is used to protect critical components from corrosion, wear, and environmental factors. It can also help to improve the performance and reliability of aircraft engines, landing gear, and other components.

Electronics Industry: In the electronics industry, aluminum plating is used to improve the electrical and thermal conductivity of components such as circuit boards, heat sinks, and connectors. It can also help to reduce electromagnetic interference (EMI) and improve the overall performance and reliability of electronic devices.

Medical Industry: In the medical industry, aluminum plating is used to create biocompatible surfaces for medical devices and implants. It can also help to improve the corrosion resistance and durability of these devices, ensuring their safety and effectiveness.

Consumer Goods Industry: In the consumer goods industry, aluminum plating is used to enhance the aesthetic appeal of products such as jewelry, watches, eyewear, and consumer electronics. It can also help to improve the durability and scratch resistance of these products, making them more attractive and long-lasting.

Our Aluminum Plating Process

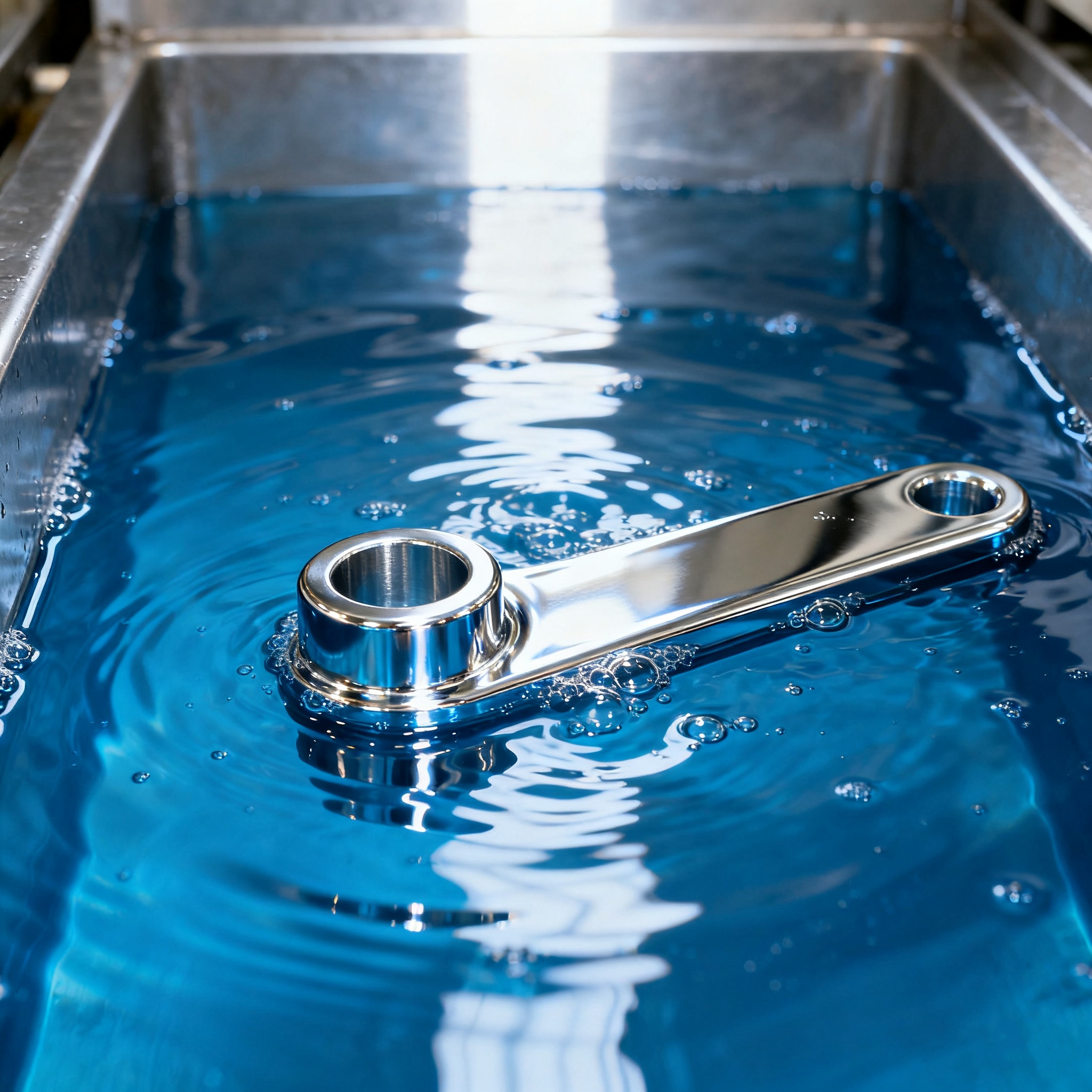

Surface Preparation: The substrate is thoroughly cleaned and pre-treated to remove any contaminants, oxides, or other impurities that could affect the adhesion of the aluminum layer. This step is crucial for ensuring a uniform and high-quality coating.

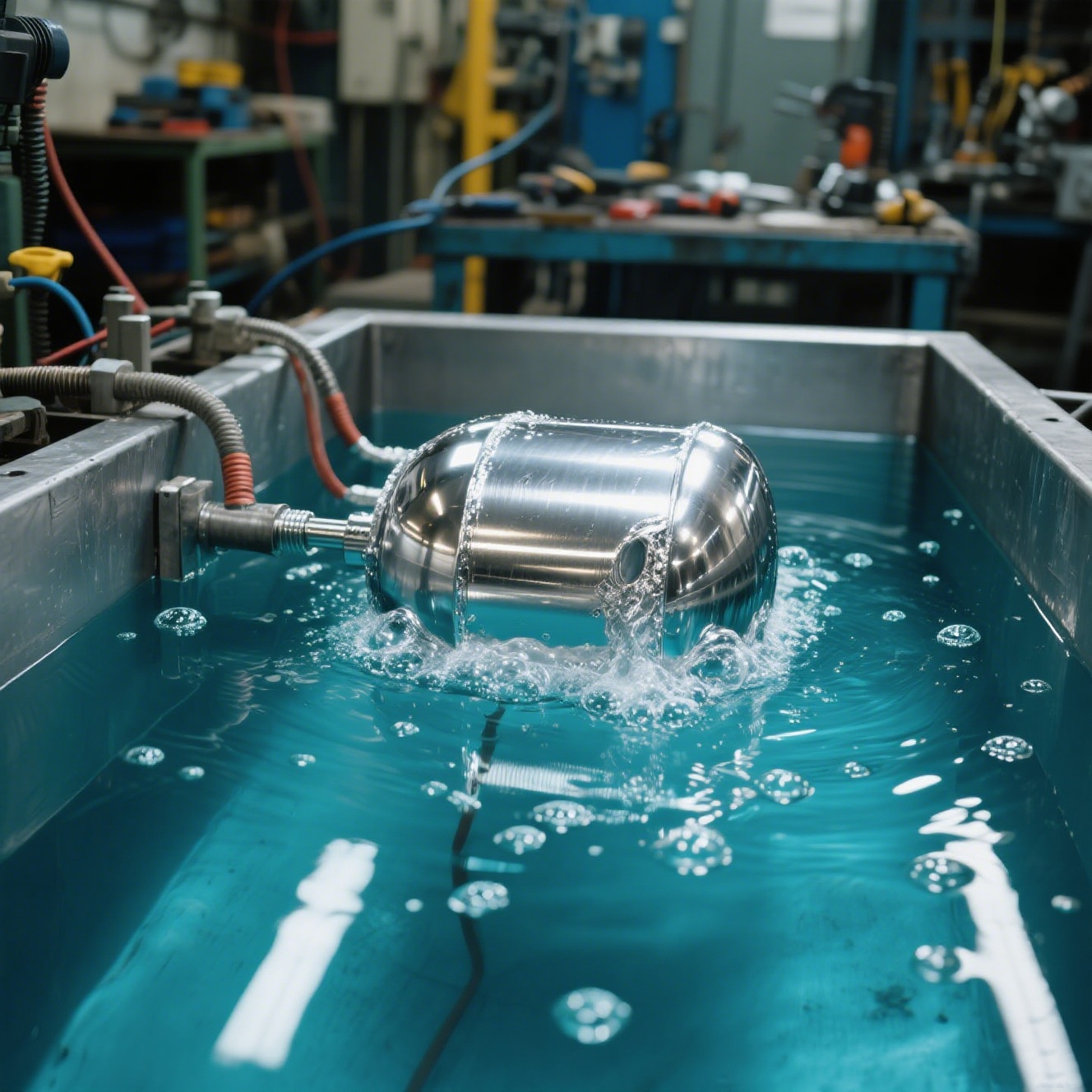

Plating: The substrate is immersed in a plating bath containing aluminum ions and other chemicals. An electric current is then applied to the bath, causing the aluminum ions to deposit onto the surface of the substrate, forming a thin, uniform layer of aluminum.

Post-Treatment: After plating, the product is rinsed, dried, and subjected to a series of post-treatment processes, such as sealing, passivation, or anodizing, to enhance the corrosion resistance, wear resistance, and aesthetic appeal of the coating.

Aluminum Plating vs. Anodizing

Feature | Aluminum Plating | Anodizing |

Coating Composition | Aluminum plating deposits a thin layer of aluminum onto the surface of the substrate. | Anodizing creates a thick, porous oxide layer on the surface of the aluminum. |

Corrosion Resistance | Aluminum plating provides excellent corrosion resistance, especially in harsh environments. | Anodizing also provides good corrosion resistance, but it may require additional sealing or coating to achieve the same level of protection as aluminum plating. |

Wear Resistance | Aluminum plating can improve the wear resistance of the substrate, especially when combined with other surface treatment methods. | Anodizing can also improve the wear resistance of the substrate, but it may not be as effective as aluminum plating in some applications. |

Aesthetic Appeal | Aluminum plating offers a wide range of finishes, from bright and shiny to matte and textured. | Anodizing offers a more limited range of finishes, but it can be dyed or colored to achieve a variety of colors and effects. |

Cost | Aluminum plating is generally more expensive than anodizing, but it offers better performance and durability in some applications. | Anodizing is a more cost-effective surface treatment method, but it may not be suitable for all applications. |

Why Choose [Our Factory Name] for Aluminum Plating?

Expertise and Experience: Our team of experienced engineers and technicians has years of experience in aluminum plating and surface treatment. We have the knowledge and skills to handle even the most complex and challenging projects, ensuring that you get the best possible results.

State-of-the-Art Technology: We use the latest technology and equipment in our aluminum plating process to ensure the highest quality results. Our advanced plating baths, precision control systems, and automated processing equipment allow us to achieve consistent, uniform coatings with excellent adhesion and performance.

Customized Solutions: We understand that every project is unique, and we work closely with our clients to develop customized solutions that meet their specific needs and requirements. Whether you need a standard aluminum plating finish or a custom-designed coating, we can help you achieve the desired results.

Quality Assurance: We are committed to providing our clients with the highest quality products and services. We follow strict quality control measures throughout the aluminum plating process to ensure that every product meets or exceeds our clients' expectations.

Competitive Pricing: We offer competitive pricing on all of our aluminum plating services without compromising on quality. We work with our clients to develop cost-effective solutions that meet their budget requirements, ensuring that you get the best possible value for your money.

| Type | Aluminum Electroplating | Entrance size | Customized at your needs |