Aluminum Plating: A Comprehensive Guide to Surface Enhancement

Aluminum Plating: A Comprehensive Guide to Surface Enhancement

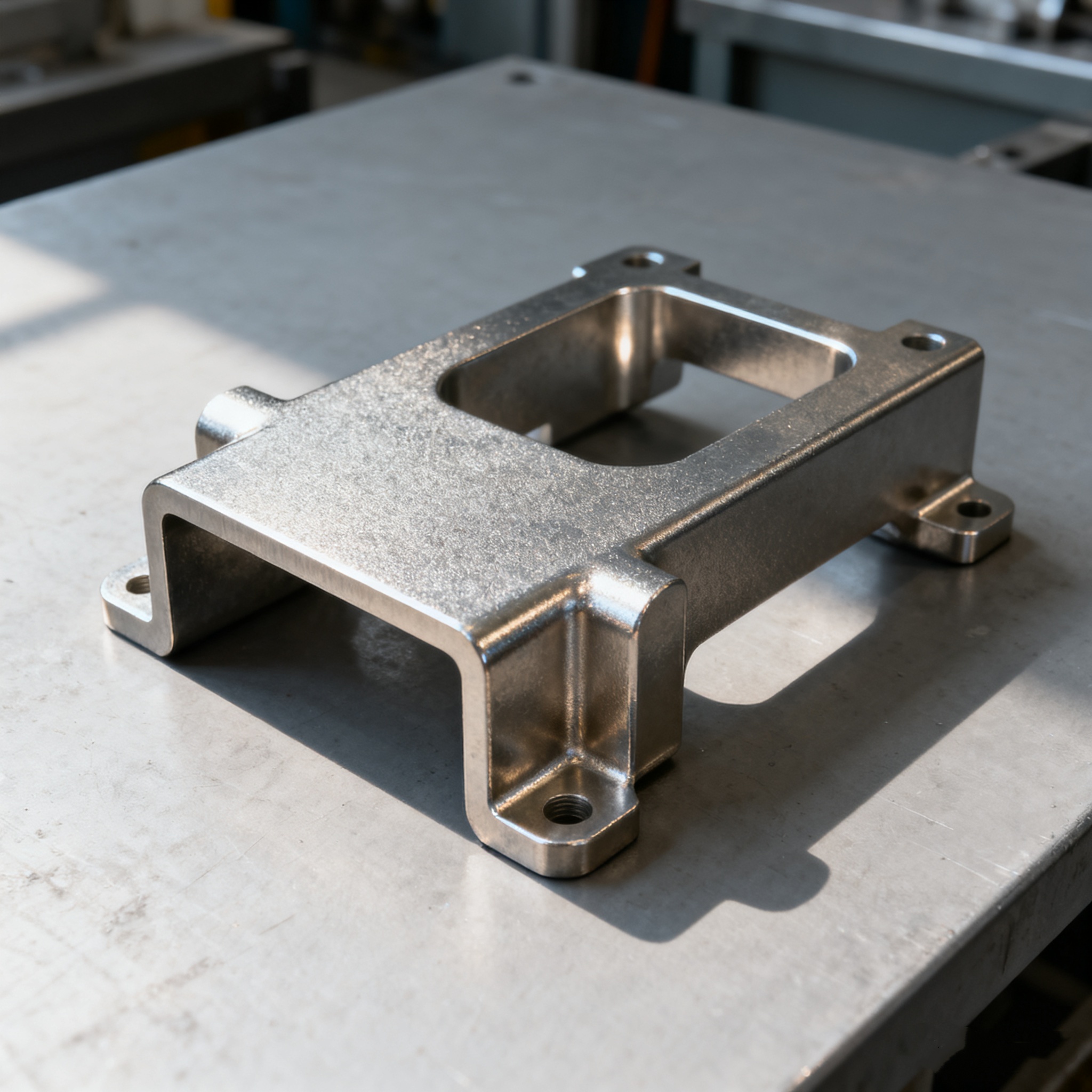

- Customized at your needs

- Aluminum Electroplating

- Customized at your needs

- Informations

- Description

Aluminum Plating: A Comprehensive Guide to Surface Enhancement

Aluminum Plating: A Comprehensive Guide to Surface Enhancement

Understanding the Aluminum Plating Process

Electrochemical Plating: In this method, the substrate is immersed in an electrolyte solution containing aluminum ions. When an electric current is passed through the solution, the aluminum ions are attracted to the negatively charged substrate and deposit as a thin layer. The thickness and uniformity of the plating can be controlled by adjusting the current density, plating time, and other process parameters.

Chemical Plating (Electroless Plating): Unlike electrochemical plating, chemical plating does not require an external electric current. Instead, it relies on a chemical reaction between the substrate and a plating solution containing reducing agents and aluminum compounds. The reducing agents trigger the deposition of aluminum onto the substrate surface, forming a self-catalyzing layer. This method is particularly useful for substrates with complex geometries or non-conductive materials, as it can coat all surfaces evenly without the need for electrical contact.

Key Advantages of Aluminum Plating

Advantage | Explanation |

Exceptional Corrosion Resistance | Aluminum naturally forms a thin, protective oxide layer upon exposure to air, which acts as a barrier against moisture, chemicals, and other corrosive substances. When plated onto a substrate, this oxide layer provides enhanced corrosion protection, making aluminum-plated components highly durable in harsh environments. |

Improved Wear Resistance | The aluminum coating can increase the hardness and abrasion resistance of the substrate. This is especially beneficial for components that experience friction, such as gears, bearings, and sliding parts, as it reduces wear and extends their service life. |

Enhanced Aesthetic Appeal | Aluminum plating offers a wide variety of finishes, from a bright, shiny mirror-like surface to a matte, textured appearance. This versatility allows for customization to meet specific design requirements, making it suitable for both functional and decorative applications. |

Good Electrical and Thermal Conductivity | Aluminum is a highly conductive material, and when plated onto a substrate, it can improve the electrical and thermal conductivity of the component. This property is valuable in applications such as electronics, where efficient heat dissipation or electrical conductivity is essential. |

Lightweight and Cost-Effective | Compared to some other metals used for plating, aluminum is lightweight, which can be advantageous in industries where weight reduction is a priority, such as aerospace and automotive. Additionally, the cost of aluminum is relatively low, making aluminum plating a cost-effective option for many applications. |

Diverse Applications of Aluminum Plating

Automotive Industry: In the automotive sector, aluminum plating is employed to enhance the corrosion resistance and appearance of components like engine parts, wheels, and exterior trim. It can also help reduce the weight of certain components, contributing to improved fuel efficiency.

Aerospace Industry: Aerospace components are often exposed to extreme conditions, and aluminum plating provides excellent protection against corrosion and wear. It is used on parts such as aircraft engine components, landing gear, and structural elements to ensure reliability and longevity.

Electronics Industry: Aluminum plating is utilized in electronics to improve electrical conductivity, shield against electromagnetic interference, and enhance heat dissipation. It is applied to circuit boards, heat sinks, and electronic enclosures to optimize the performance of electronic devices.

Marine Industry: Marine environments are highly corrosive, and aluminum plating offers robust protection for ship hulls, propellers, and other marine equipment. This helps prevent rust and degradation, ensuring the safety and operational efficiency of vessels.

Consumer Goods: From smartphones and laptops to kitchen appliances and jewelry, aluminum plating adds a touch of elegance and durability to consumer products. Its aesthetic appeal and resistance to scratches and wear make products more appealing to consumers.

Aluminum Plating vs. Anodizing

Feature | Aluminum Plating | Anodizing |

Coating Formation | Involves depositing a layer of aluminum from an external source onto the substrate. | Creates an oxide layer by growing it directly on the surface of the aluminum substrate through an electrochemical process within the material itself. |

Coating Thickness | Can achieve a wide range of thicknesses, from very thin decorative layers to thicker protective coatings. | Typically results in a thicker oxide layer, but the thickness is more limited compared to the potential range of aluminum plating. |

Color and Finish Options | Offers a broader range of colors and finishes, as different alloys and coloring agents can be used during the plating process. | Color options are more restricted, mainly achieved through dyes or pigments absorbed by the porous oxide layer, and the finishes are often more limited in variety. |

Hardness and Wear Resistance | Can provide high hardness and wear resistance, especially when combined with appropriate post-treatment processes. | Hardness varies, and hard anodizing is required to achieve high hardness levels, which is a more complex and costly process compared to some aluminum plating techniques for enhancing wear resistance. |

Cost | Generally, aluminum plating can be more expensive, especially for complex plating processes or when high-quality finishes are required. However, it may offer better performance in certain applications. | Anodizing is often more cost-effective for basic surface treatment needs, but additional costs may be incurred for hard anodizing or special coloring requirements. |

| Type | Aluminum Electroplating | Entrance size | Customized at your needs |