Aluminum Casting: The Future-Forward Manufacturing Solution

Aluminum Casting: The Future-Forward Manufacturing Solution

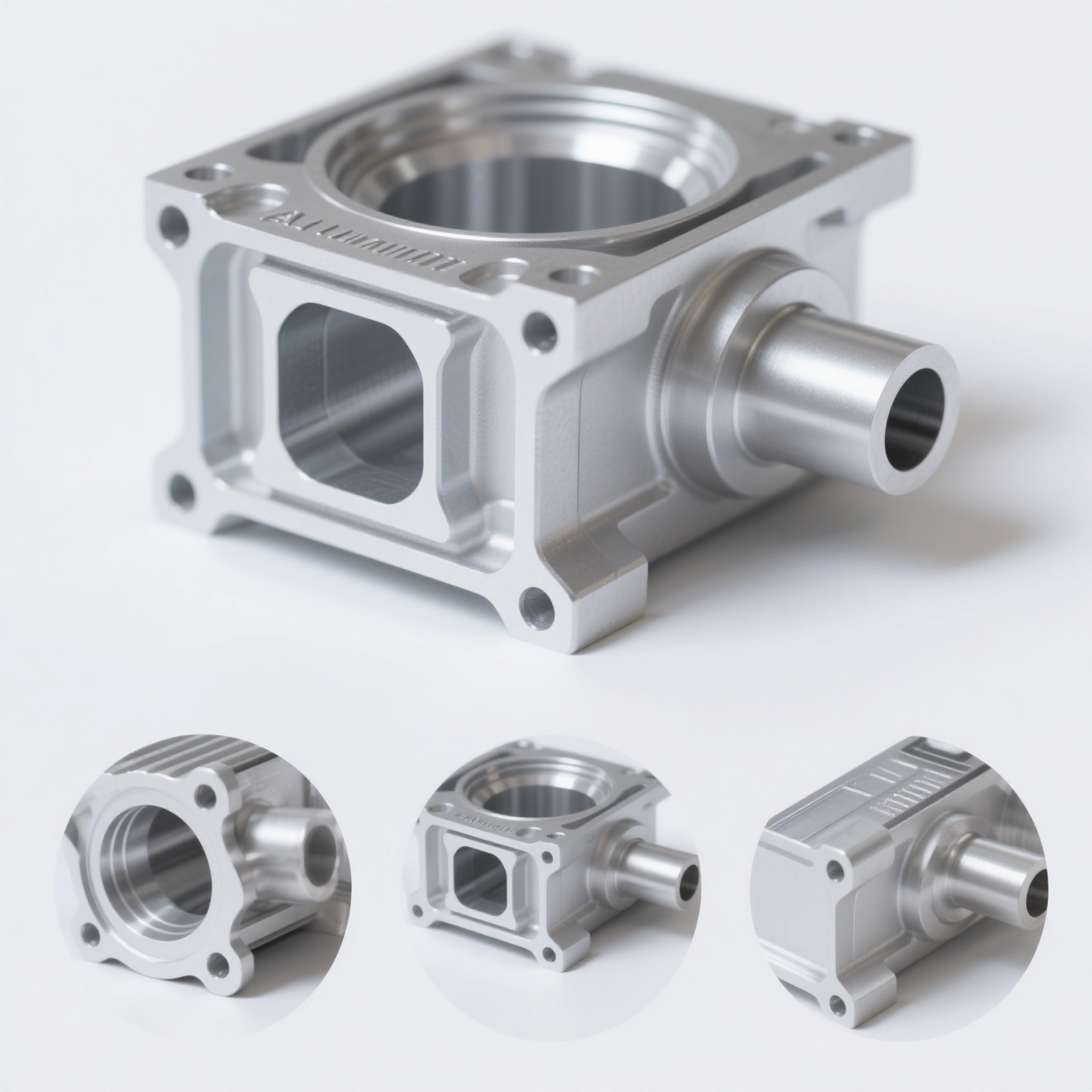

- Customized

- Precision Casting

- Customized

- Informations

- Description

Aluminum Casting: The Future-Forward Manufacturing Solution

Aluminum Casting: The Future-Forward Manufacturing Solution

In the ever-evolving landscape of manufacturing, aluminum casting has firmly established itself as a game-changer, driving innovation and excellence across multiple industries. Its remarkable capabilities have not only transformed traditional manufacturing processes but also opened up new possibilities for cutting-edge applications. Let's explore in detail why aluminum casting is the go-to choice for forward-thinking manufacturers.

Revolutionary Applications Redefining Industries

The influence of aluminum casting extends far beyond conventional uses. In the emerging field of electric vehicles (EVs), aluminum castings play a pivotal role. Battery enclosures made through aluminum casting not only provide robust protection for the crucial battery packs but also contribute to weight reduction, thereby extending the vehicle's range. For instance, some leading EV manufacturers have reported a 15 - 20% reduction in battery enclosure weight using aluminum casting, directly translating to a 10 - 12% increase in driving range.

In the medical device industry, aluminum casting is being utilized to create highly precise and durable components. Surgical instruments crafted from aluminum castings offer superior strength and corrosion resistance, ensuring long - term reliability in sterile operating environments. Additionally, in the development of advanced prosthetics, aluminum castings allow for the creation of lightweight yet sturdy frames that enhance the comfort and mobility of patients.

Industry | Innovative Applications | Impact Metrics |

Electric Vehicles | Battery enclosures | 15 - 20% weight reduction, 10 - 12% increase in driving range |

Medical Devices | Surgical instruments, prosthetic frames | Extended product lifespan, enhanced patient comfort |

Robotics | Lightweight robotic arms | 30% faster movement speed, reduced energy consumption |

Unparalleled Features and Benefits

Advanced Material Properties

Aluminum alloys used in casting possess a unique set of properties. They can be engineered to have high tensile strength, reaching up to 500 MPa in some specialized alloys, while maintaining a relatively low density of around 2.7 g/cm³. This means that components can endure significant mechanical stress without adding excessive weight, which is critical in industries like aerospace where every ounce matters.

Sustainable Manufacturing

Aluminum is one of the most sustainable materials in manufacturing. It is infinitely recyclable without losing its properties, and recycling aluminum requires only 5% of the energy needed to produce primary aluminum. By choosing aluminum casting, manufacturers are not only getting high - quality products but also contributing to a circular economy. For example, approximately 75% of all aluminum ever produced is still in use today, thanks to its recyclability.

Integration with Advanced Technologies

Aluminum casting seamlessly integrates with state - of - the - art manufacturing technologies. 3D printing of casting molds has revolutionized the prototyping process, reducing lead times from weeks to days. Additionally, the use of simulation software in the casting process allows for precise prediction of casting quality, minimizing the occurrence of defects and saving both time and resources.

Compelling Reasons for Selection

When compared to alternative manufacturing methods and materials, aluminum casting stands out prominently. In contrast to machining from solid blocks, aluminum casting can produce complex geometries with internal cavities and thin - walled structures in one piece, reducing the need for multiple parts and assembly. Compared to plastics, aluminum castings offer superior heat resistance, mechanical strength, and dimensional stability, making them more suitable for high - performance applications.

Production - Oriented Advantages

Lean Manufacturing Enablement

Aluminum casting processes are highly conducive to lean manufacturing principles. The ability to produce near - net - shape components reduces material waste significantly. For example, in die casting, the material utilization rate can reach up to 95%, minimizing the environmental impact and cost associated with scrap.

Scalability and Adaptability

Manufacturers can easily scale up or down the production of aluminum castings based on market demand. With the use of modular casting molds, it is possible to quickly switch between different product designs, providing a high level of flexibility in production. This scalability makes aluminum casting an ideal choice for both small - batch custom production and large - scale mass production.

In summary, aluminum casting is not just a manufacturing process; it is a strategic choice for manufacturers aiming to stay ahead in a competitive market. Its wide - ranging applications, exceptional material properties, and production - friendly features make it the key to unlocking new levels of efficiency, innovation, and sustainability in manufacturing. Embrace aluminum casting today and embark on a journey towards a more advanced and prosperous manufacturing future.

| Type | Precision Casting | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)