Aluminum Parts Precision Casting

Precision Aluminum Casting: Redefining Manufacturing Excellence

- Customized

- Precision Casting

- Customized

- Informations

- Description

Precision Aluminum Casting: Redefining Manufacturing Excellence

Precision Aluminum Casting: Redefining Manufacturing Excellence

At our state-of-the-art factory, we take pride in being a leading professional manufacturer specializing in aluminum products. Among our comprehensive range of advanced processing techniques, precision casting stands out as a cornerstone of our manufacturing prowess. With years of expertise and a commitment to innovation, we have perfected the art and science of precision aluminum casting, delivering exceptional products that meet the most demanding industry standards.

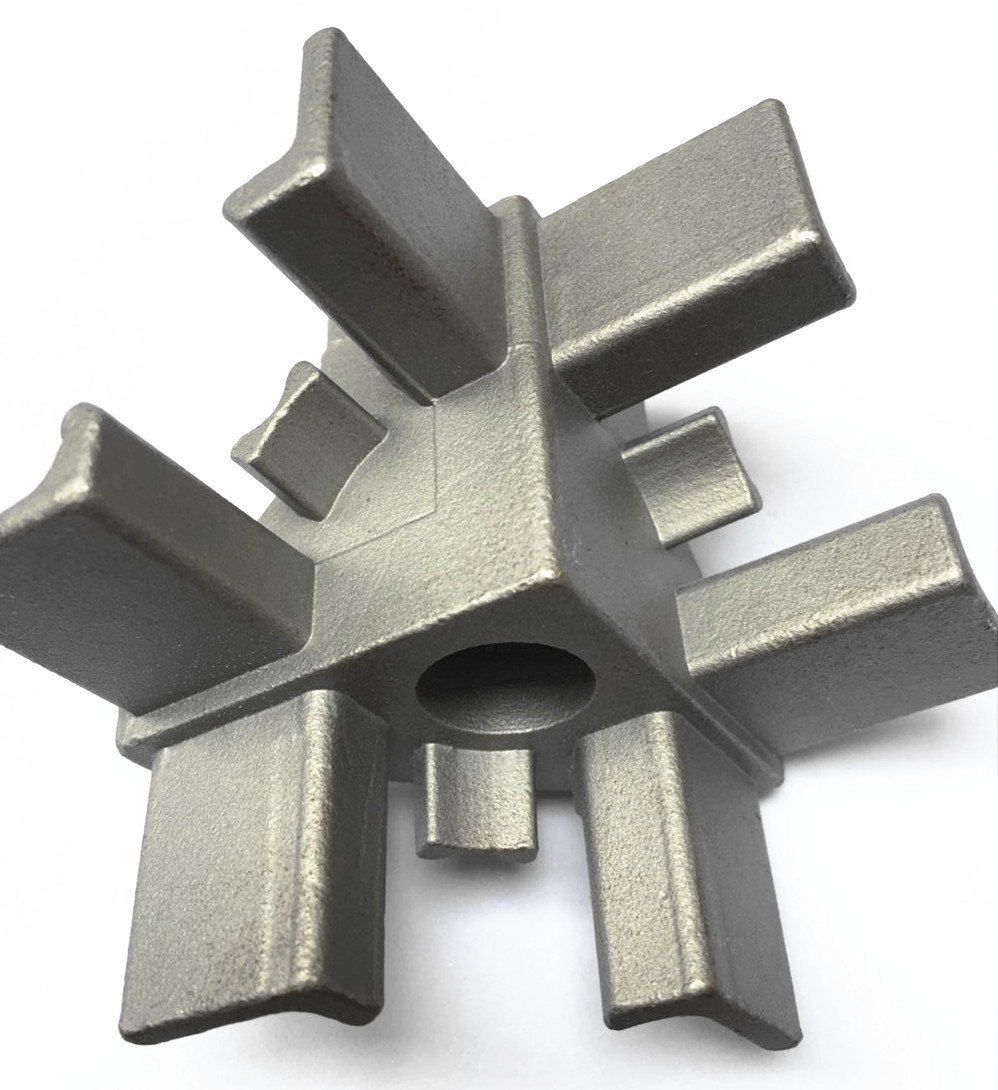

Precision casting, also known as investment casting, is a highly sophisticated manufacturing process that allows us to create intricate and complex aluminum components with unparalleled accuracy and surface finish. This technique involves creating a wax pattern, which is then coated with a ceramic shell. The wax is melted out, leaving a hollow ceramic mold, into which molten aluminum is poured. Once the aluminum solidifies, the ceramic shell is removed, revealing a near-net-shape casting that requires minimal post-processing.

Unmatched Process Characteristics

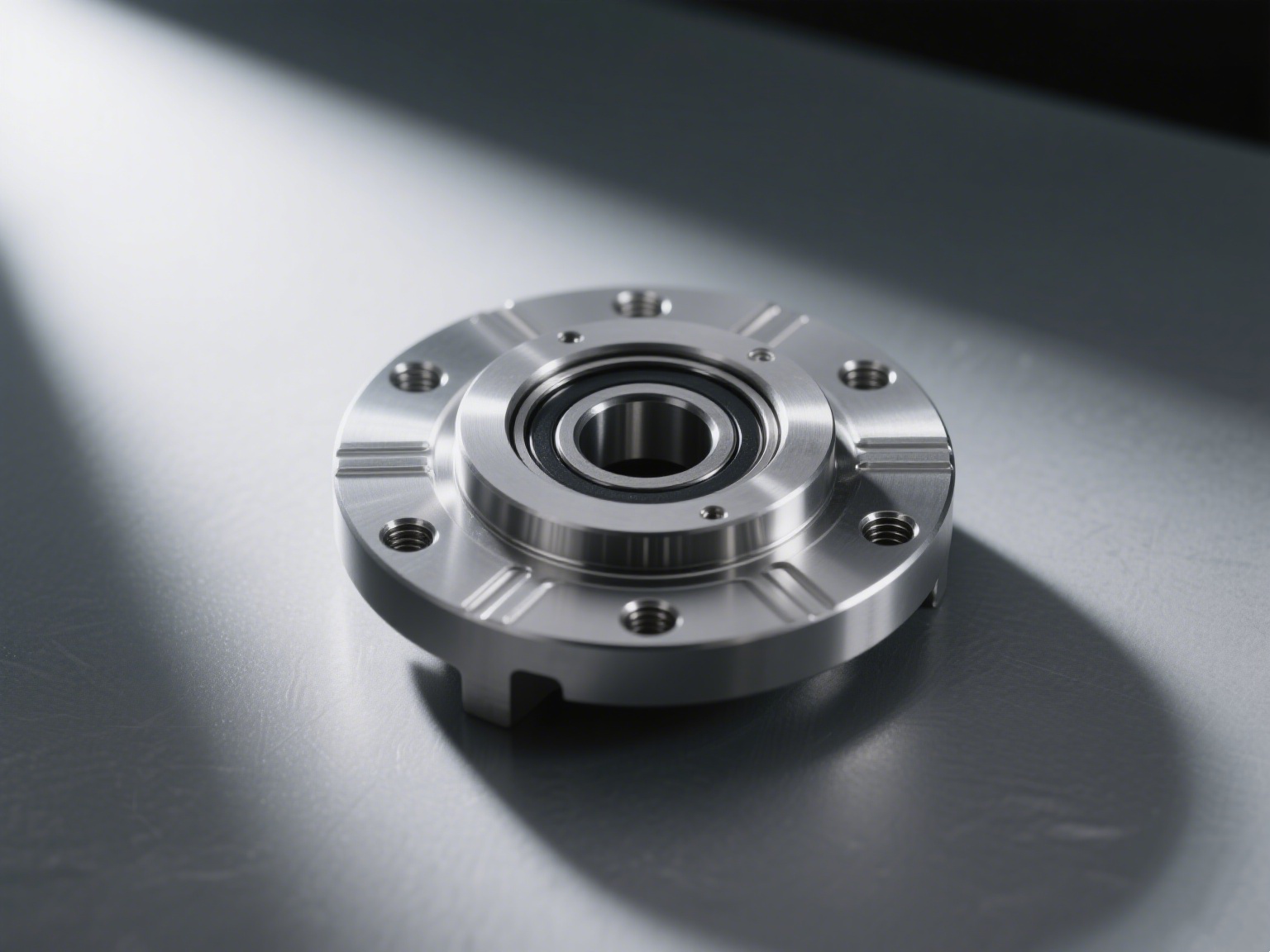

Our precision casting process is defined by several key characteristics that set it apart from traditional manufacturing methods. First and foremost is the ability to achieve extraordinary dimensional accuracy. We consistently maintain tolerances within ±0.1mm, ensuring that each component fits perfectly into its intended assembly. This level of precision is crucial in industries such as aerospace, automotive, and medical, where even the smallest deviation can have significant consequences.

Another notable characteristic is the ability to produce components with intricate geometries and thin walls. Our advanced wax pattern technology and ceramic shell systems enable us to create complex shapes that would be impossible or extremely costly to manufacture using other methods. Whether it’s a highly detailed aerospace bracket or a delicate medical instrument component, we have the expertise to bring your most challenging designs to life.

The surface finish of our precision castings is also remarkable. With a roughness average (Ra) of 1.6μm or better, our components often require little to no secondary finishing, saving both time and cost for our customers. This smooth surface not only enhances the aesthetic appeal of the product but also improves its functional performance, such as reducing friction or enhancing corrosion resistance.

Outstanding Advantages

Our precision aluminum casting process offers a multitude of advantages that provide significant value to our customers. One of the primary benefits is the ability to work with a wide range of aluminum alloys. From high-strength 6061 and 7075 to corrosion-resistant 5052 and heat-treatable 2024, we have the expertise to cast almost any aluminum alloy, tailored to your specific application requirements.

This versatility allows us to serve a diverse range of industries. In the aerospace sector, our precision castings are used in critical components such as engine mounts and structural brackets, where weight reduction and high strength are paramount. In the automotive industry, we produce lightweight engine components and chassis parts that improve fuel efficiency and performance. And in the medical field, our precision castings are used in surgical instruments and implantable devices, where biocompatibility and precision are essential.

Another significant advantage is the cost-effectiveness of our process, especially for medium to high-volume production runs. While the initial tooling costs for precision casting may be higher than some other methods, the reduced need for secondary machining and the ability to produce complex shapes in a single operation result in lower overall production costs over time. This makes precision casting an excellent choice for companies looking to balance quality and affordability.

Our Differentiating Edge

What truly sets us apart from our competitors is our unwavering commitment to quality and innovation. We have invested heavily in state-of-the-art equipment and technology, including advanced 3D printing for wax patterns, computerized molten metal temperature control systems, and comprehensive non-destructive testing (NDT) capabilities. This allows us to maintain the highest level of quality control throughout the entire manufacturing process.

Our team of experienced engineers and technicians is another key differentiator. With decades of combined expertise in precision casting, they are able to tackle the most challenging projects and provide valuable design feedback to optimize components for casting. We work closely with our customers from the initial design phase to final production, ensuring that every detail is considered and every requirement is met.

We also pride ourselves on our flexibility and responsiveness. Whether you need a small batch of prototypes or a large-scale production run, we have the capacity and agility to accommodate your needs. Our streamlined production processes and efficient project management ensure that we deliver your components on time, every time.

To further illustrate the advantages of our precision casting process, here is a comparison table highlighting how it measures up against other common manufacturing methods:

Criteria | Precision Casting | CNC Machining | Die Casting |

Dimensional Accuracy | ±0.1mm | ±0.05mm | ±0.2mm |

Complexity of Geometry | High | Medium | Medium |

Thin Wall Capability | Excellent | Good | Good |

Surface Finish (Ra) | 1.6μm | 0.8μm | 3.2μm |

Material Versatility | Wide range of aluminum alloys | Limited to machinable alloys | Limited to specific die casting alloys |

Production Volume Suitability | Medium to high | Low to medium | High |

Tooling Costs | Moderate to high | Low to moderate | High |

Post-Processing Requirements | Minimal | Significant | Some |

At our factory, we are more than just a manufacturer – we are your partner in precision. Whether you have a complex design challenge or a need for high-quality aluminum components, our precision casting expertise and commitment to excellence will ensure that you receive the best possible product and service. Contact us today to discover how our precision aluminum casting can transform your ideas into reality.

| Type | Precision Casting | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)