Aluminum Casting: Precision, Performance, and Versatility

Aluminum Casting: Precision, Performance, and Versatility

- Customized

- Precision Casting

- Customized

- Informations

- Description

Aluminum Casting: Precision, Performance, and Versatility

Unleashing the Power of Aluminum Casting: Precision, Performance, and Versatility

In the dynamic realm of modern manufacturing, Aluminum Casting has emerged as a cornerstone technology, revolutionizing the way industries produce high-quality components. Renowned for its exceptional versatility, precision, and cost-effectiveness, aluminum casting has become the material of choice for a wide range of applications across diverse sectors. This article delves into the intricacies of aluminum casting, exploring its applications, key features, and the compelling reasons why it stands out as the optimal solution for manufacturing needs.

Applications of Aluminum Casting

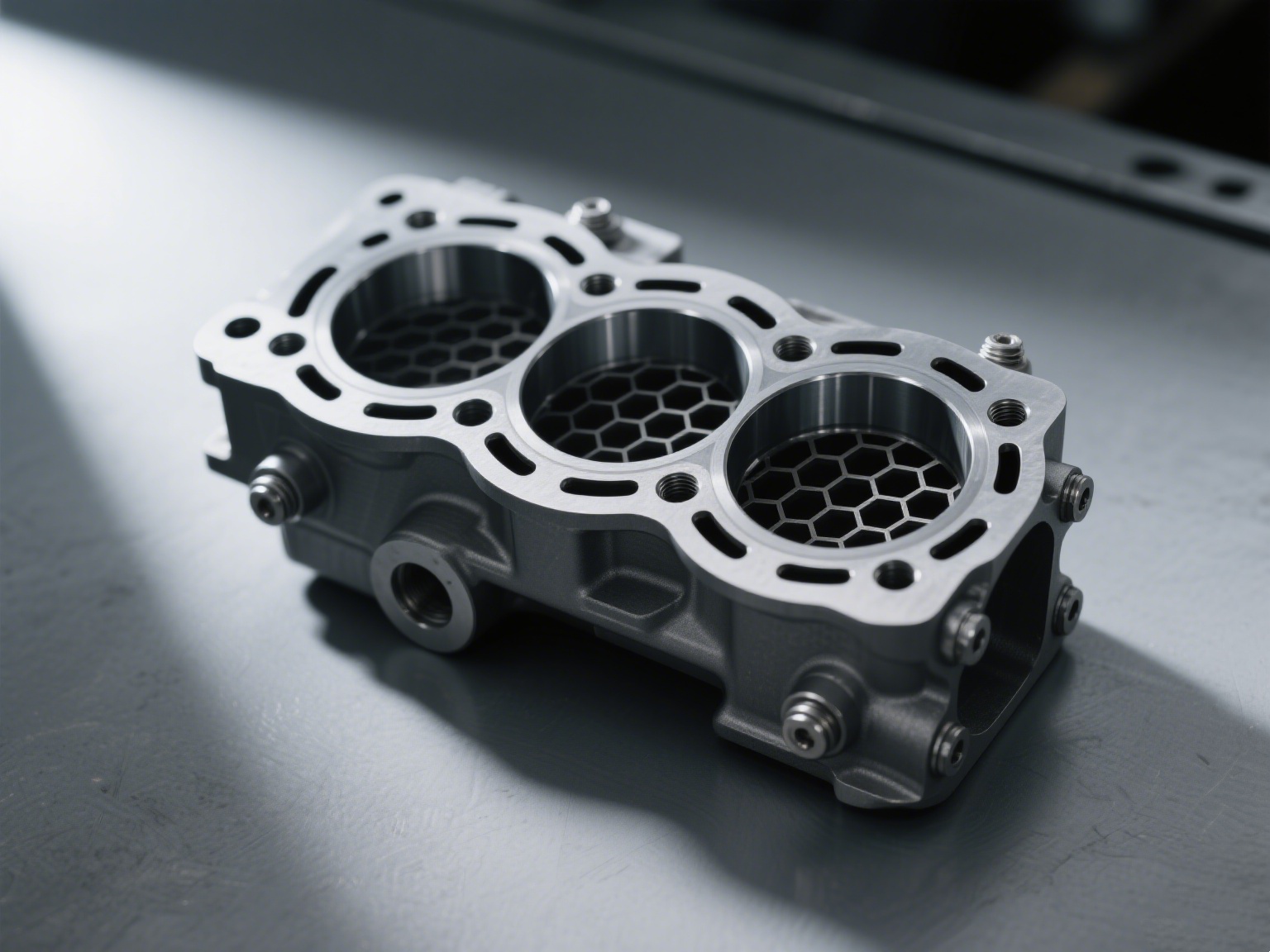

Aluminum casting's adaptability makes it suitable for a vast array of products and industries. In the automotive industry, it is used to produce engine blocks, cylinder heads, transmission cases, and suspension components, enhancing fuel efficiency and performance. The aerospace sector relies on aluminum casting for critical parts such as wing spars, fuselage sections, and engine components, taking advantage of its lightweight yet robust properties. In the consumer goods industry, aluminum casting is employed to create stylish and durable products, including cookware, furniture, and electronics enclosures. Additionally, the marine, defense, and renewable energy sectors benefit from the corrosion resistance and strength of aluminum castings in applications ranging from ship propellers to military equipment and wind turbine components.

Industry | Typical Products |

Automotive | Engine blocks, cylinder heads, transmission cases, suspension components |

Aerospace | Wing spars, fuselage sections, engine components |

Consumer Goods | Cookware, furniture, electronics enclosures |

Marine | Ship propellers, marine hardware |

Defense | Military equipment, armored vehicle components |

Renewable Energy | Wind turbine components, solar panel frames |

Key Features and Advantages of Aluminum Casting

Lightweight and High Strength-to-Weight Ratio

Aluminum is approximately one-third the weight of steel, making aluminum castings an ideal choice for applications where weight reduction is crucial. Despite its low density, aluminum offers excellent strength and durability, ensuring that components can withstand heavy loads and harsh operating conditions. This combination of lightweight and high strength-to-weight ratio translates into improved fuel efficiency, reduced energy consumption, and enhanced performance in vehicles and aircraft.

Corrosion Resistance

Aluminum naturally forms a thin, protective oxide layer on its surface, which acts as a barrier against corrosion. This inherent corrosion resistance makes aluminum castings highly suitable for applications in harsh environments, such as marine, aerospace, and outdoor settings. Unlike other metals, aluminum does not rust or corrode easily, reducing the need for frequent maintenance and extending the lifespan of components.

Design Flexibility

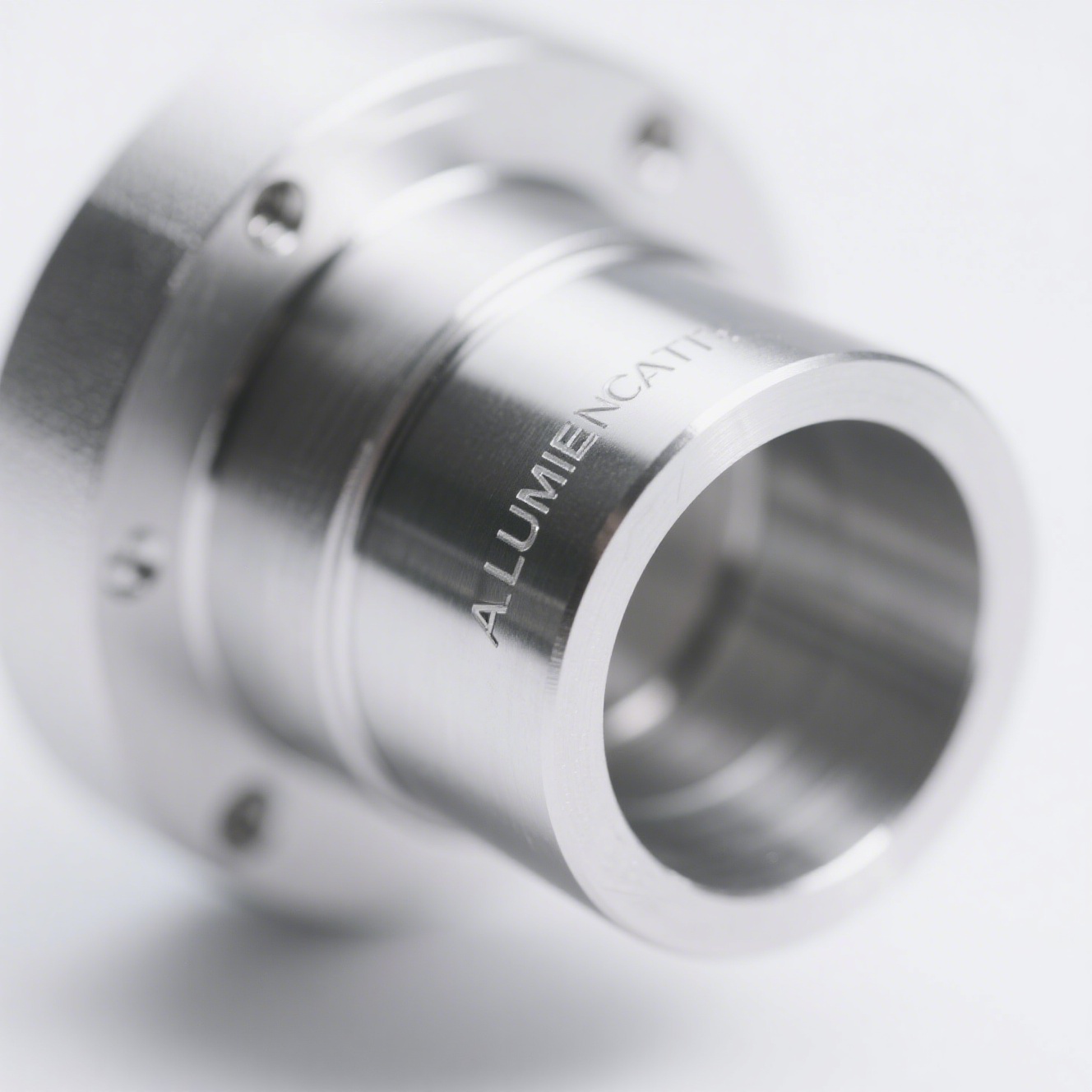

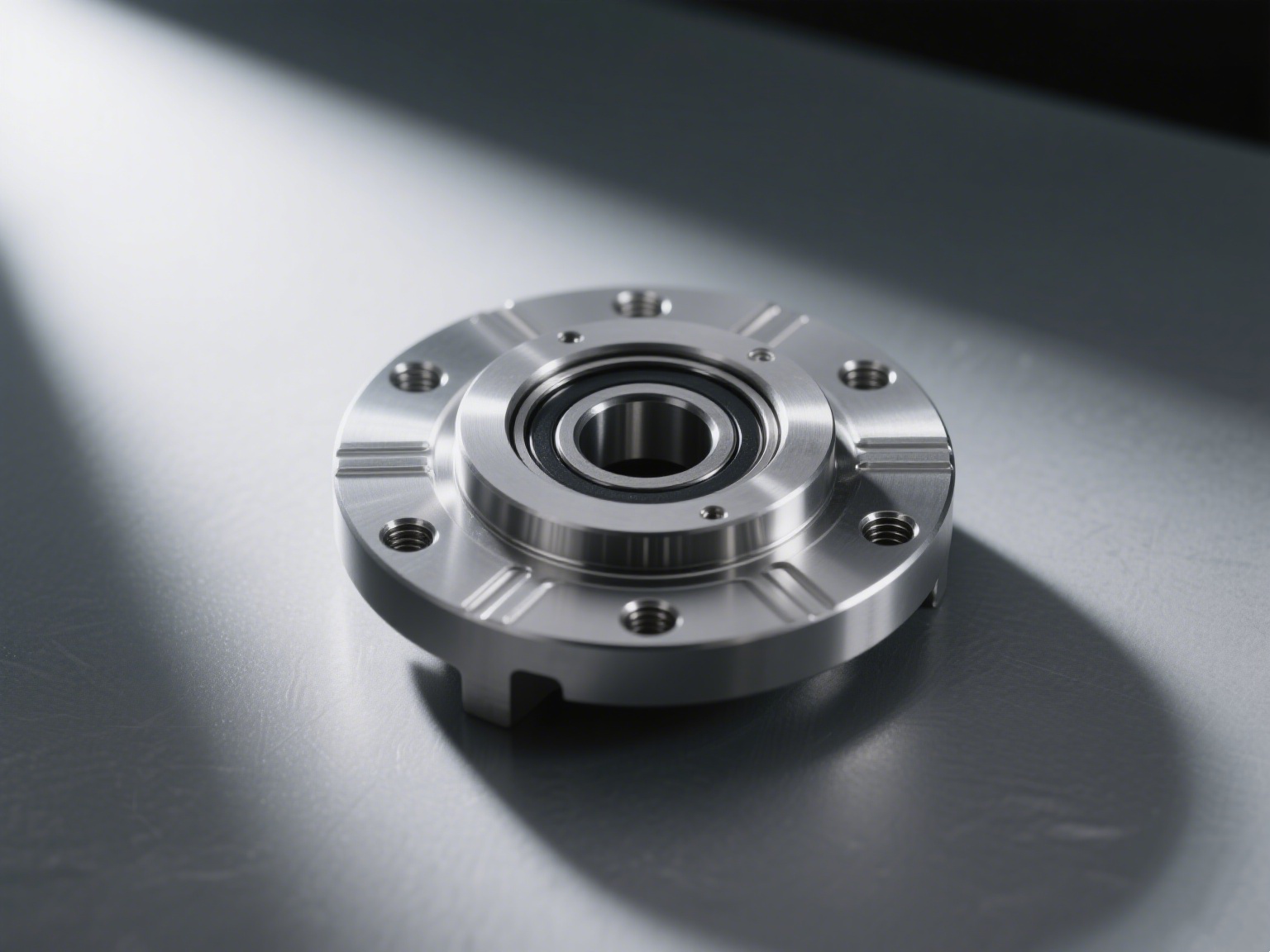

Aluminum casting allows for the creation of complex geometries and intricate designs that are difficult or impossible to achieve with other manufacturing processes. Advanced casting techniques, such as die casting and investment casting, enable the production of components with precise tolerances, fine details, and internal passages. This design flexibility allows manufacturers to optimize the performance and functionality of their products, while also reducing the number of individual components and assembly steps.

Cost-Effectiveness

Aluminum is one of the most abundant metals on Earth, making it relatively inexpensive compared to other engineering materials. Additionally, the high recyclability of aluminum further reduces its environmental impact and cost. Aluminum casting processes are also highly efficient, with high production rates and low material waste. These factors combine to make aluminum casting a cost-effective solution for large-scale manufacturing, without compromising on quality or performance.

Thermal and Electrical Conductivity

Aluminum has excellent thermal and electrical conductivity, making it suitable for applications that require efficient heat dissipation or electrical conductivity. In the electronics industry, aluminum castings are used to manufacture heat sinks, enclosures, and electrical connectors, ensuring optimal performance and reliability. In the automotive industry, aluminum's thermal conductivity helps to dissipate heat from engine components, preventing overheating and improving engine efficiency.

Why Choose Aluminum Casting?

When it comes to manufacturing high-quality components, aluminum casting offers a multitude of advantages over other materials and processes. Its unique combination of lightweight, strength, corrosion resistance, design flexibility, cost-effectiveness, and thermal and electrical conductivity makes it the ideal choice for a wide range of applications across diverse industries. Whether you are looking to improve the performance of your products, reduce costs, or enhance their environmental sustainability, aluminum casting provides the solution you need.

Production Advantages of Aluminum Casting

High Production Rates

Aluminum casting processes, such as die casting and sand casting, are capable of producing large quantities of components in a relatively short period of time. This high production rate makes aluminum casting suitable for mass production applications, where efficiency and productivity are essential.

Consistent Quality

Aluminum casting processes are highly controlled and repeatable, ensuring consistent quality and dimensional accuracy of components. Advanced casting techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), enable precise mold design and production, resulting in components that meet strict quality standards.

Reduced Assembly Time and Costs

Aluminum casting allows for the production of complex components in a single piece, reducing the need for multiple individual parts and assembly steps. This not only simplifies the manufacturing process but also reduces assembly time and costs, improving overall productivity and profitability.

Customization Options

Aluminum casting offers a high degree of customization, allowing manufacturers to produce components that meet specific design and performance requirements. With a wide range of casting techniques, alloys, and finishing options available, aluminum castings can be tailored to suit the unique needs of each application.

In conclusion, aluminum casting is a versatile, reliable, and cost-effective manufacturing process that offers numerous advantages for a wide range of industries. Its unique combination of properties, design flexibility, and production capabilities make it the material of choice for producing high-quality components that meet the demanding requirements of modern applications. Whether you are in the automotive, aerospace, consumer goods, marine, defense, or renewable energy sector, aluminum casting provides the solution you need to achieve your manufacturing goals. Contact us today to learn more about how aluminum casting can benefit your business and take your products to the next level.

| Type | Precision Casting | Entrance size | Customized |

Get the latest prices? We will respond as soon as possible (within 12 hours)