Precision Casting: Elevating Aluminum Component Manufacturing at ShanFeng

Precision Casting: Elevating Aluminum Component Manufacturing at ShanFeng

- Customized at your needs

- Aluminum Casting

- Customized at your requirements

- Informations

- Description

Precision Casting: Elevating Aluminum Component Manufacturing at ShanFeng

Precision Casting: Elevating Aluminum Component Manufacturing at ShanFeng

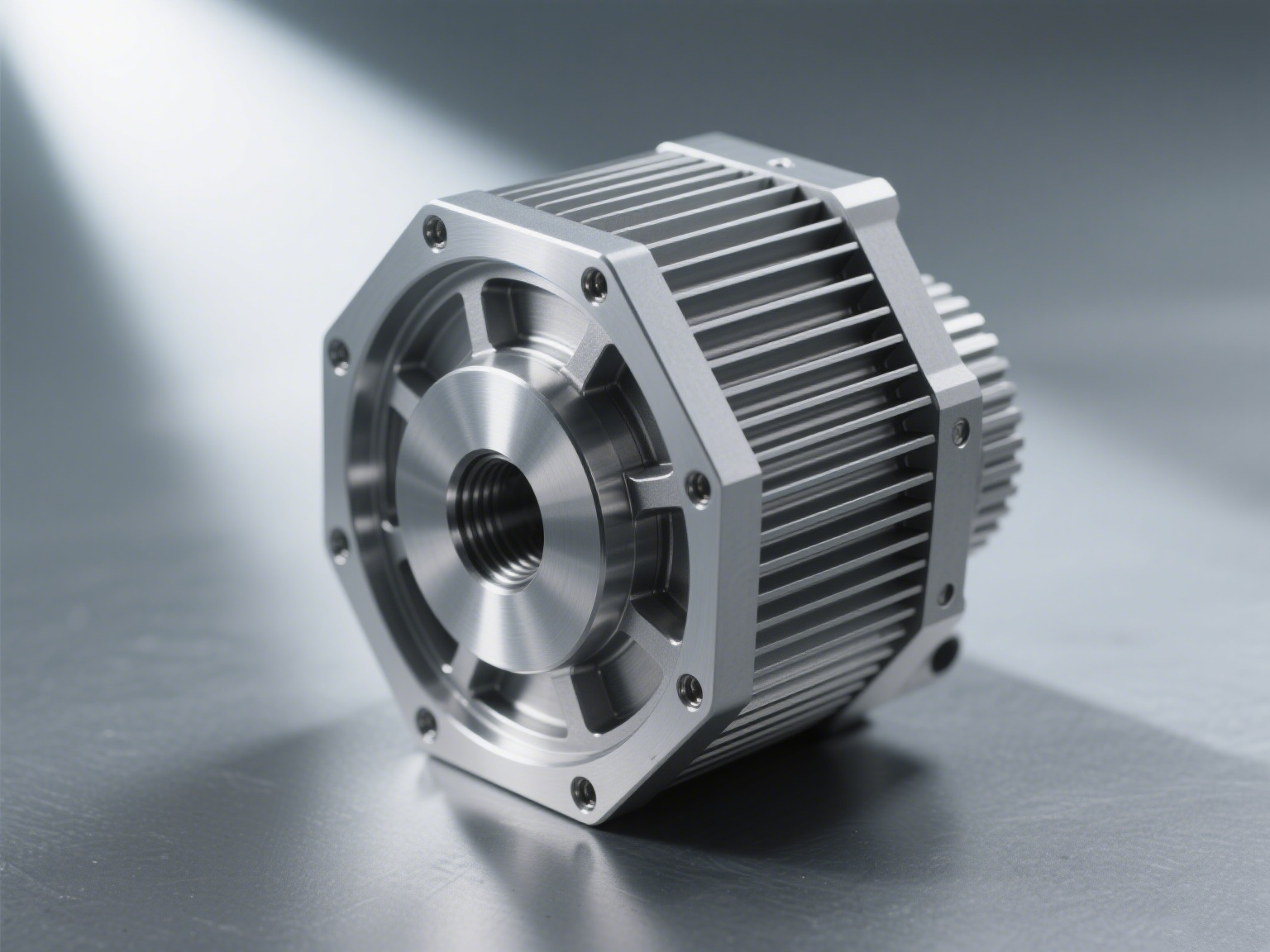

At ShanFeng, we take pride in our comprehensive range of manufacturing processes, and precision casting for aluminum parts is a standout offering. It empowers us to serve a wide array of industries with components that are precise, reliable, and tailored to perfection.

1. Understanding the Precision Casting Workflow

2. Industry - Wide Applications and Use Cases

| Industry | Application Contexts | Aluminum Component Examples |

| Construction | Manufacturing of architectural hardware, structural connectors. Aluminum's lightweight and corrosion resistance are beneficial. | Curtain wall brackets, door handle components |

| Food and Beverage | Production of parts for food processing equipment. Hygienic and easy - to - clean aluminum castings are preferred. | Conveyor belt components, food mixer parts |

| Telecommunications | Fabrication of components for communication towers, equipment enclosures. Aluminum's strength - to - weight ratio is advantageous. | Antenna mountings, telecom cabinet parts |

| Toys and Recreation | Creation of high - quality toys, gaming equipment components. Precision casting ensures durability and aesthetic appeal. | High - end action figure parts, gaming controller components |

3. Distinctive Production Traits of Precision Casting

4. The Merits of Choosing Our Precision Casting

Precision casting is more than just a manufacturing process at ShanFeng; it's a commitment to excellence in aluminum component production. As part of our extensive suite of manufacturing services, we leverage precision casting to help our customers across various industries achieve their goals, whether it's developing innovative products or improving the performance of existing systems. Trust us to bring your aluminum component designs to life with the precision and quality that precision casting can offer.

| Type | Aluminum Casting | Entrance size | Customized at your requirements |