Precision Casting: A Pillar of Advanced Aluminum Manufacturing at ShanFeng

Precision Casting: A Pillar of Advanced Aluminum Manufacturing at ShanFeng

- Custmoized at your demands

- Aluminum Casting

- Customized at your needs

- Informations

- Description

Precision Casting: A Pillar of Advanced Aluminum Manufacturing at ShanFeng

Precision Casting: A Pillar of Advanced Aluminum Manufacturing at ShanFeng

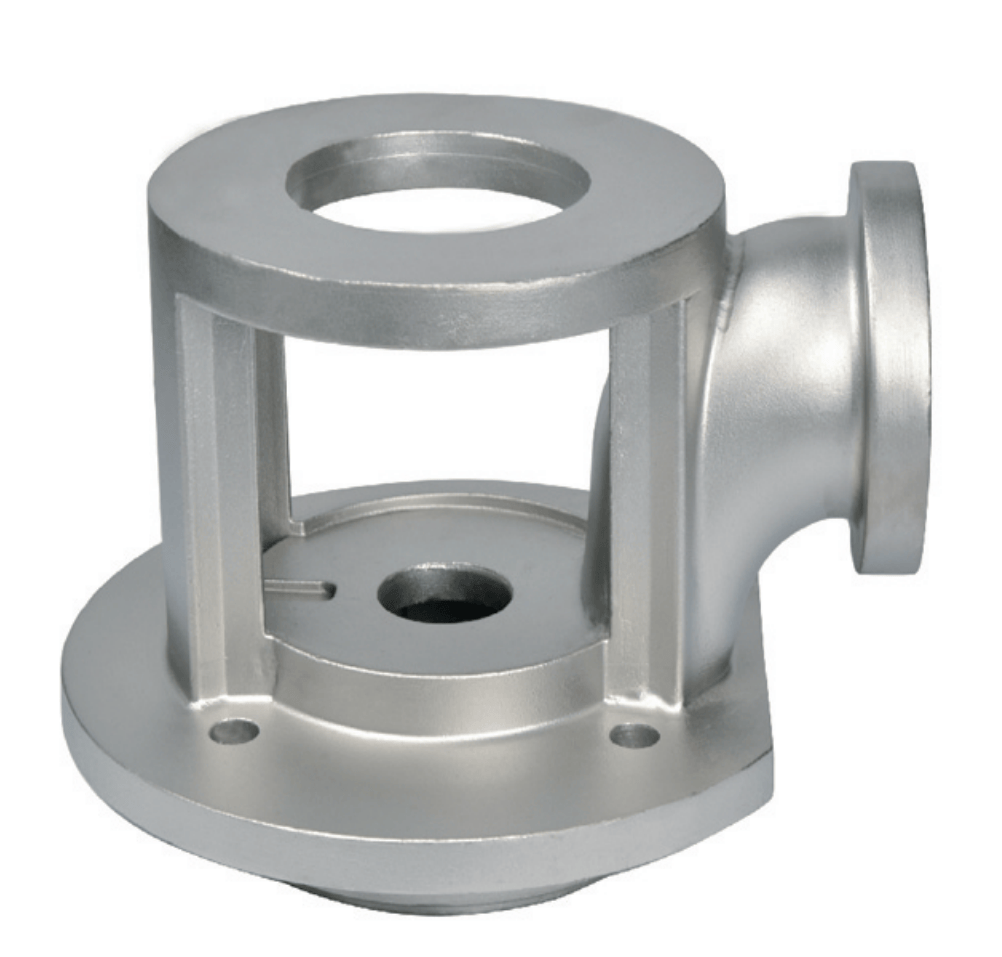

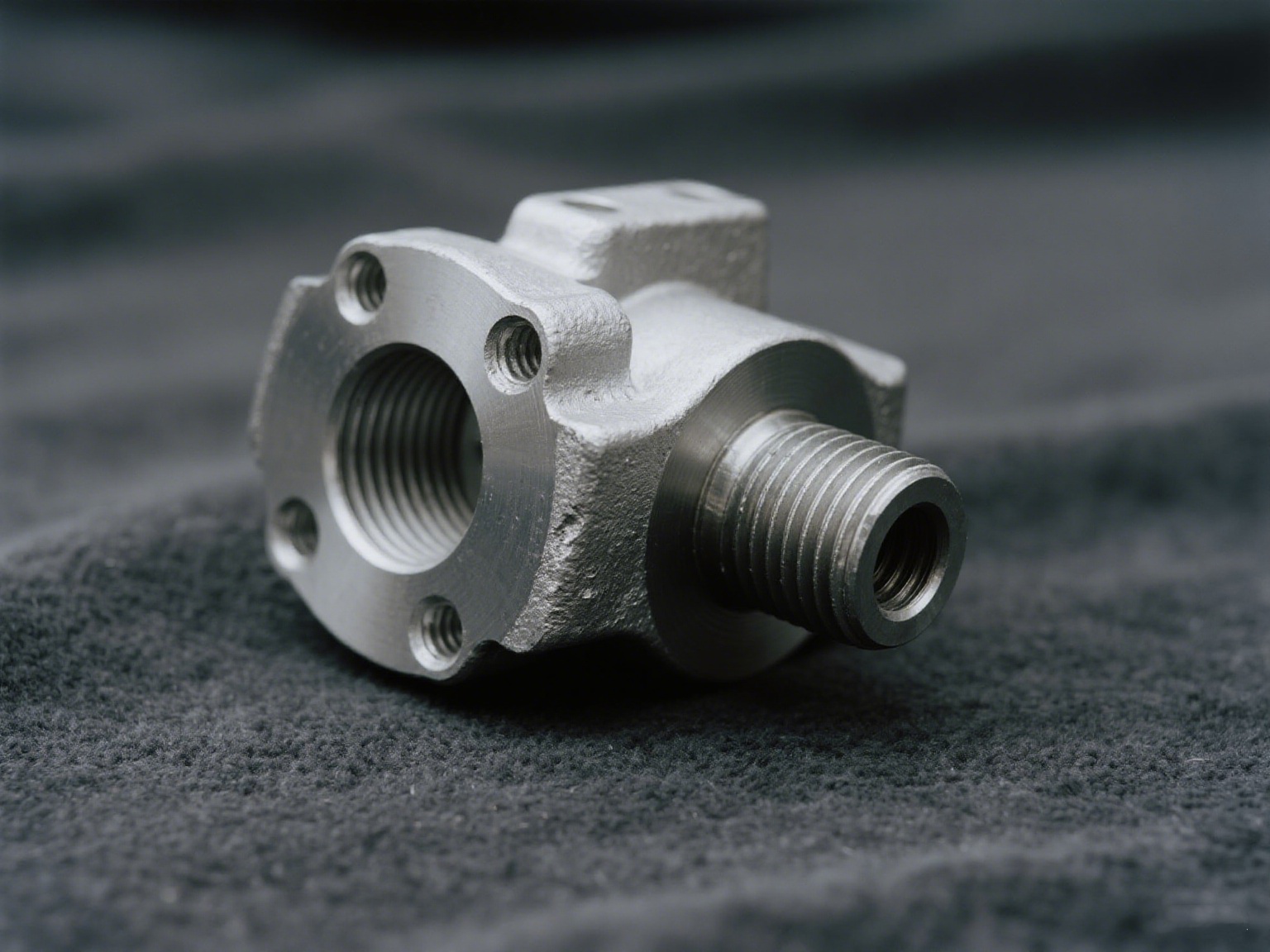

In the realm of modern manufacturing, precision casting has emerged as a vital technique, and at ShanFeng, it plays a significant role in our portfolio of diverse processing capabilities.

Our precision casting services for aluminum parts are engineered to deliver superior quality and performance, catering to a multitude of industries.

1. The Precision Casting Process Unveiled

Precision casting, a sophisticated lost - wax casting methodology for aluminum, commences with the design and creation of a wax model that mirrors the exact dimensions and features

of the intended aluminum component. This wax model is sequentially immersed in a refractory ceramic slurry. After each dip, the slurry is allowed to dry, building up a robust ceramic shell

around the wax. Once the shell has achieved the required thickness and hardness, the wax is removed through a heating process, creating a hollow mold. Molten aluminum is then poured

into this mold under controlled conditions. Once the aluminum has solidified, the ceramic shell is carefully broken away, revealing the precision - cast aluminum part. Post - casting operations

such as machining, heat treatment, or surface finishing can be carried out to meet specific requirements.

2. Industry Applications and Scenarios

| Industry Sector | Typical Application Scenarios | Representative Aluminum Components |

| Defense | Production of components for military vehicles, weapon systems. Aluminum's lightweight and high - strength properties are valuable for mobility and performance. | Tank turret components, rifle barrel supports |

| Renewable Energy | Manufacturing of parts for solar and wind energy systems. Precision - cast aluminum helps in creating efficient and durable components. | Solar panel mounting brackets, wind turbine hub components |

| Marine | Fabrication of parts for boats and marine equipment. Corrosion - resistant aluminum castings (with proper treatment) are ideal for the marine environment. | Boat engine mounts, propeller shaft components |

| Consumer Goods | Creation of high - end consumer products like luxury watches, sports equipment. Precision and aesthetic appeal are key. | Watch cases, golf club heads |

3. Production Characteristics of Precision Casting

Dimensional Accuracy: Our precision casting processes can achieve extremely tight dimensional tolerances, often in the range of ±0.05mm for critical dimensions. This level of accuracy ensures seamless integration of parts into larger assemblies.

Design Flexibility: It offers unparalleled design flexibility, enabling the production of parts with complex undercuts, internal cavities, and fine - detailed features. Designers are not restricted by the limitations of traditional manufacturing methods.

Batch Production Capability: Whether it's a small batch of highly customized parts or large - scale production runs, precision casting can be adapted to meet the volume requirements while maintaining consistent quality.

4. The Edge of Our Precision Casting

Quality Assurance: Our state - of - the - art quality control systems monitor every step of the precision casting process, from wax pattern creation to the final inspection of the cast aluminum part. This ensures that only parts meeting the highest quality standards leave our facility.

Customization Expertise: We specialize in custom - made precision - cast aluminum parts. Our team of engineers and technicians works closely with customers to understand their unique design and performance requirements, translating them into high - quality castings.

Speed and Efficiency: Despite the complexity of the process, our optimized precision casting workflows enable us to deliver parts in a timely manner, meeting project deadlines without compromising on quality.

Precision casting is a testament to our dedication to providing advanced manufacturing solutions at ShanFeng. Alongside our other machining and fabrication services, we strive to be the partner of choice for industries seeking high - performance,

precision - cast aluminum components. Let us help you transform your design concepts into reality with the precision and reliability that precision casting offers.

| Type | Aluminum Casting | Entrance size | Customized at your needs |