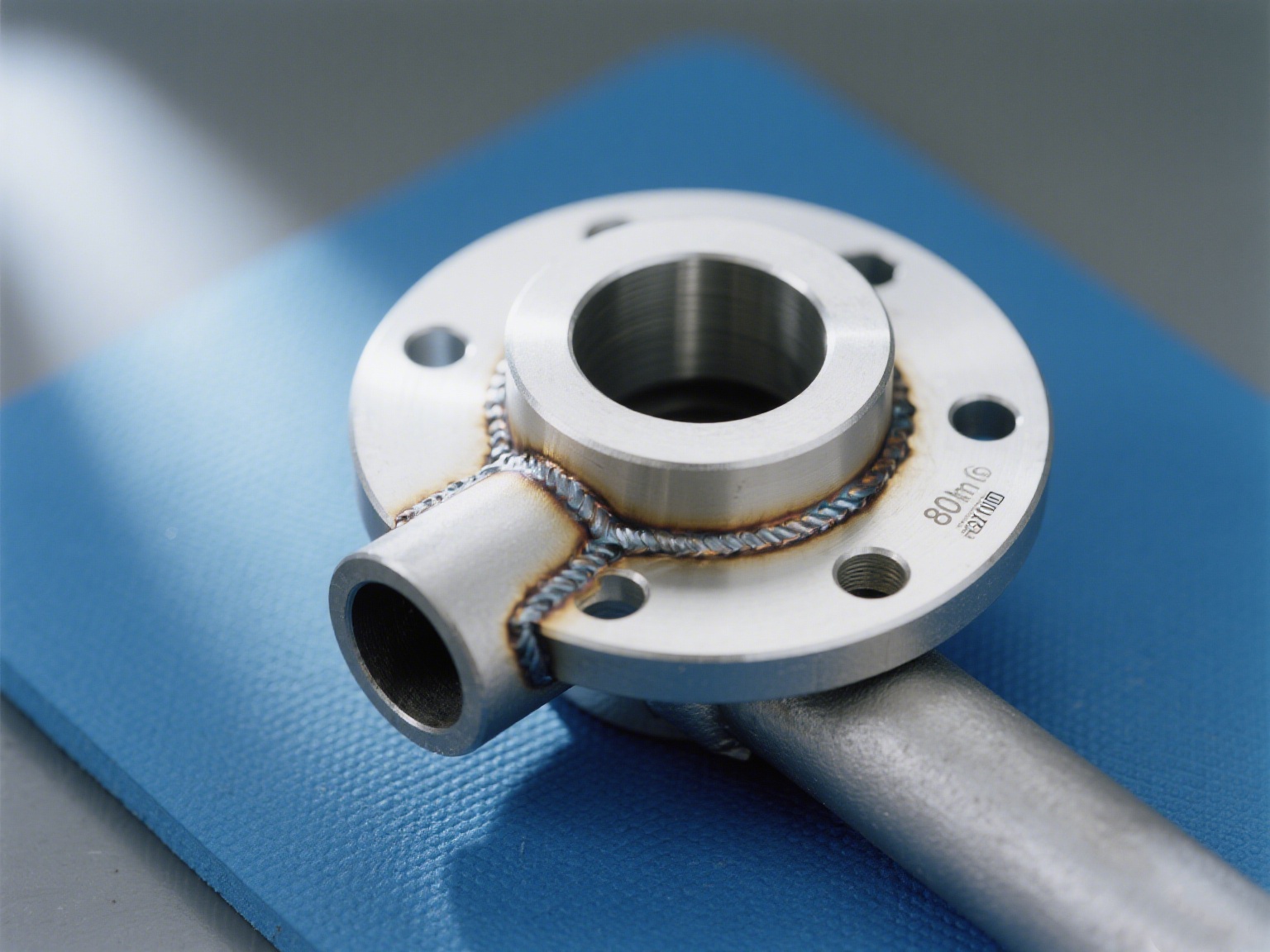

Precision aluminum parts welding

Aluminum Welding for Machinery Parts: Precision, Durability, and Expertise

- Customized at your needs

- Aluminum parts welding

- Customized at your needs

- Informations

- Description

Aluminum Welding for Machinery Parts: Precision, Durability, and Expertise

Aluminum Welding for Machinery Parts: Precision, Durability, and Expertise

Why Aluminum Welding Matters for Machinery Parts

Structural integrity: Welds that withstand vibrations, pressure, and heavy loads.

Corrosion resistance: Proper techniques that maintain aluminum's natural ability to resist rust, crucial for outdoor or industrial settings.

Dimensional accuracy: Minimized distortion to keep parts fitting and functioning as designed.

Longevity: Reduced need for repairs or replacements, lowering overall operational costs.

Techniques for Aluminum Welding in Machinery Manufacturing

Gas Tungsten Arc Welding (GTAW/TIG): Ideal for thin sections and high-precision parts, TIG welding offers exceptional control over the weld pool, producing clean, strong joints without spatter. It's often used for critical components like hydraulic manifolds or engine brackets.

Gas Metal Arc Welding (GMAW/MIG): Suitable for thicker aluminum sections and high-volume production, MIG welding uses a wire electrode and shielding gas to create efficient, consistent welds. It's a popular choice for structural machinery parts like frames or support beams.

Friction Stir Welding (FSW): A solid-state welding process that uses friction and pressure to join aluminum without melting, FSW eliminates issues like porosity or cracking, making it perfect for high-strength, high-performance machinery parts.

Why Choose a Specialized Aluminum Welding Service for Machinery Parts?

Experience with machinery-specific challenges: Professionals who focus on machinery parts understand the unique demands of industrial equipment—from heavy-duty load requirements to exposure to oils, chemicals, and extreme conditions.

Advanced equipment: Access to state-of-the-art welding machines, precision tools, and quality control systems ensures consistent, reliable results.

Compliance with industry standards: Whether it's ISO, AWS, or industry-specific certifications, reputable welders adhere to strict guidelines to guarantee safety and performance.

Custom solutions: From prototyping to large-scale production, specialized services can tailor welding processes to meet specific part designs and performance needs.

Invest in Quality Aluminum Welding for Your Machinery

| Type | Aluminum parts welding | Entrance size | Customized at your needs |