Aluminum CNC Components

Aluminum CNC Components

- Customized

- CNC

- Customized

- Informations

- Description

Aluminum CNC Components

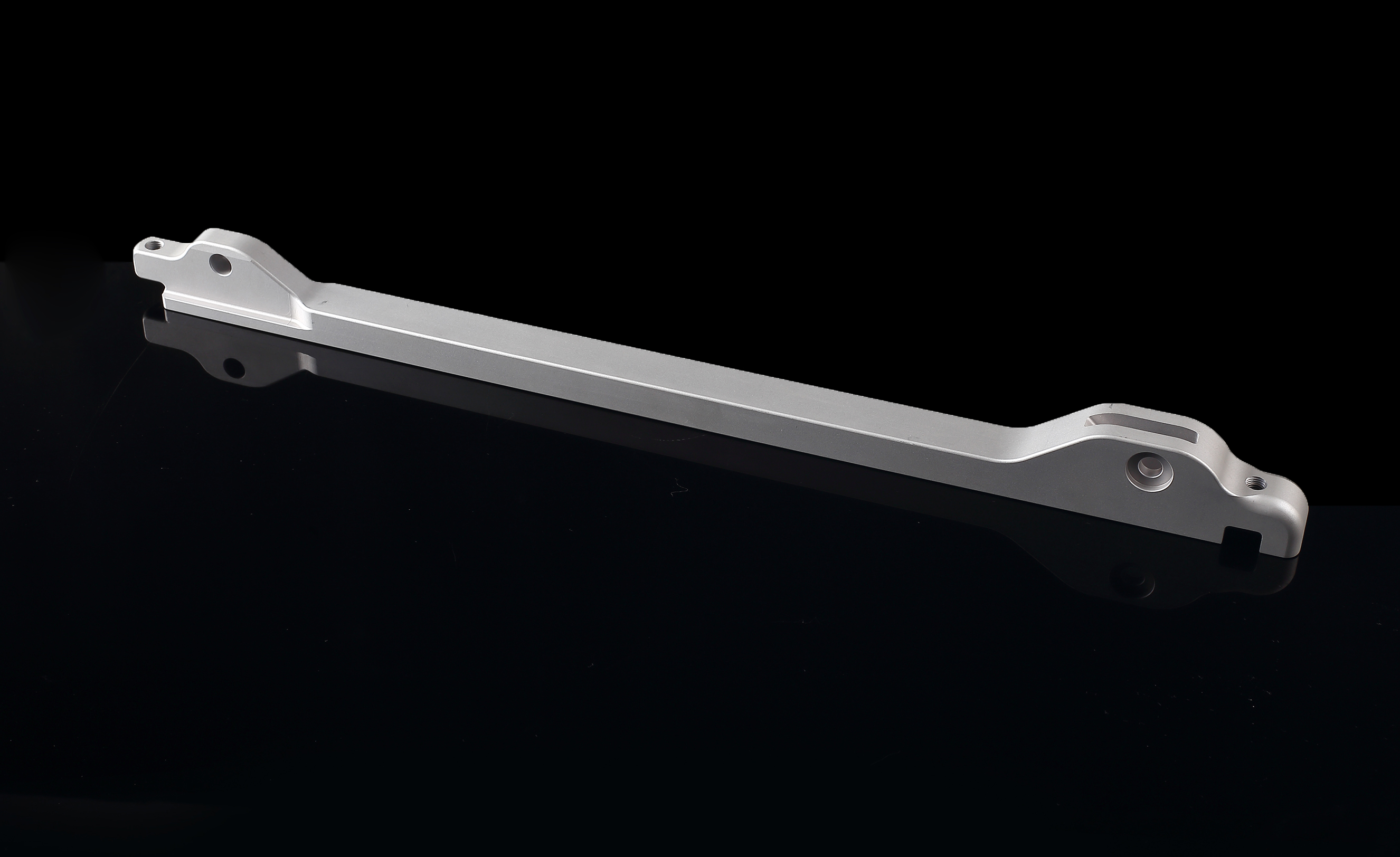

Aluminum CNC Components: Precision Crafted Connecting Rods for High-Performance Applications

Redefine Performance with Engineering Excellence

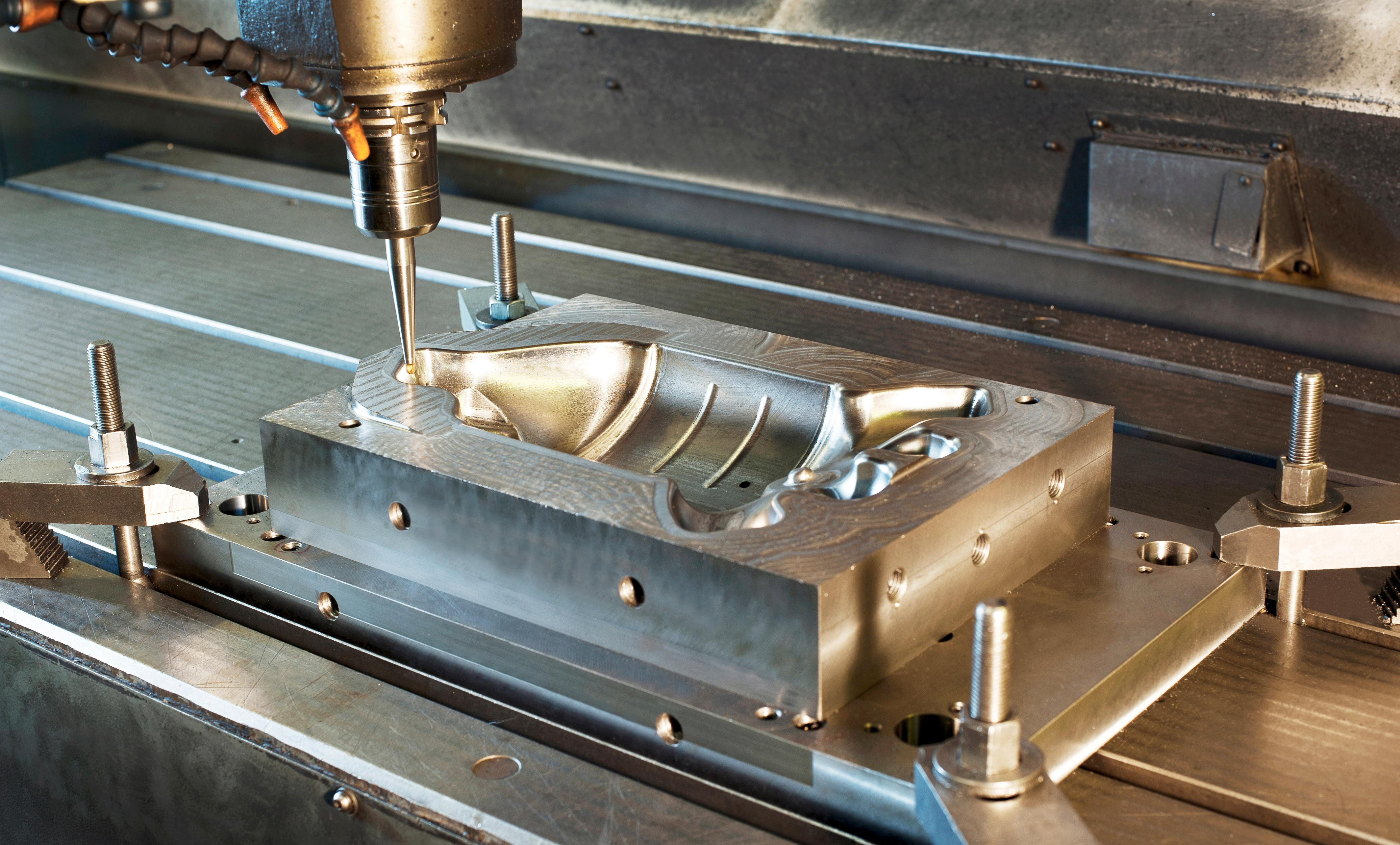

The Science Behind Our Aluminum Connecting Rods

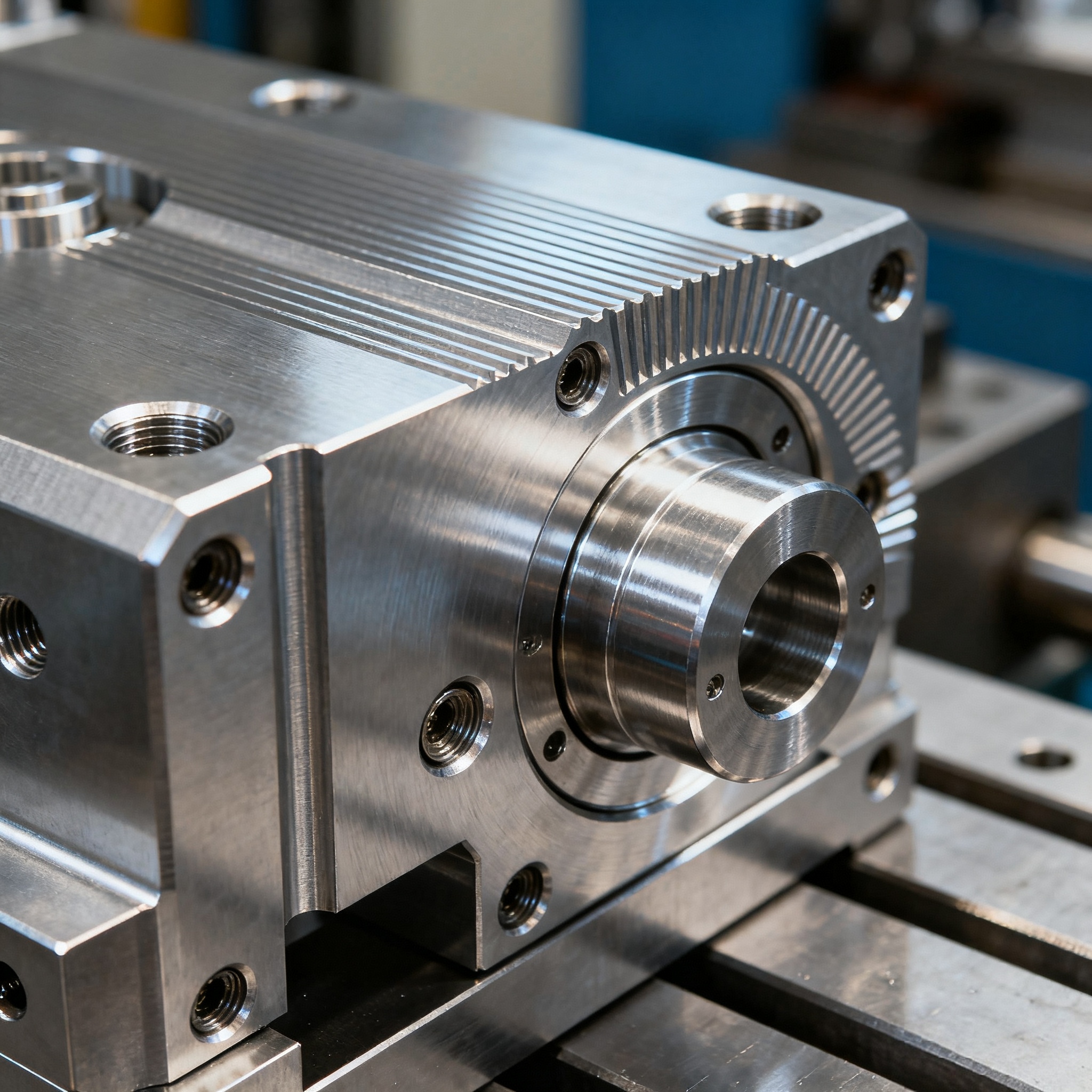

Technical Feature | Engineering Advantage | Performance Impact |

Multi-axis CNC Machining | Complex geometries with polished surfaces | Reduced friction, improved energy transfer |

Stress Relief Annealing | Eliminates machining-induced stresses | 30% higher fatigue resistance than standard rods |

Micro-arc Oxidation (MAO) Coating | Corrosion protection for marine/chemical environments | Service life extended by 2x in harsh conditions |

Dynamic Balancing | High-speed rotational stability | Vibration reduction at 10,000+ RPM |

Case Study: Racing Engine Connecting Rods

Hollow-core design to cut weight by 22%

FEA-optimized fillet radii to eliminate stress concentrations

DLC (diamond-like carbon) coating on bearing surfaces

Industry Applications & Custom Solutions

Automotive: Forged aluminum rods for turbocharged engines

Aerospace: Heat-treated rods for aircraft landing gear

Robotics: Lightweight rods for high-cycle robotic arms

Medical Devices: Bio-compatible aluminum rods for surgical tools

1, Dye penetrant inspection for surface flaws

2, Tensile testing to verify yield strength

3, CMM (coordinate measuring machine) scanning for dimensional accuracy

Client Testimonial: "Game-Changer in Aerospace Manufacturing"

Ready to optimize your mechanical systems?

Request a quote today and experience how our aluminum CNC components redefine performance boundaries.

| Type | CNC | Entrance size | Customized |