CNC Aluminum Machining

CNC Aluminum Machining

- Customized.

- CNC machining

- Customized

- Informations

- Description

CNC Aluminum Machining

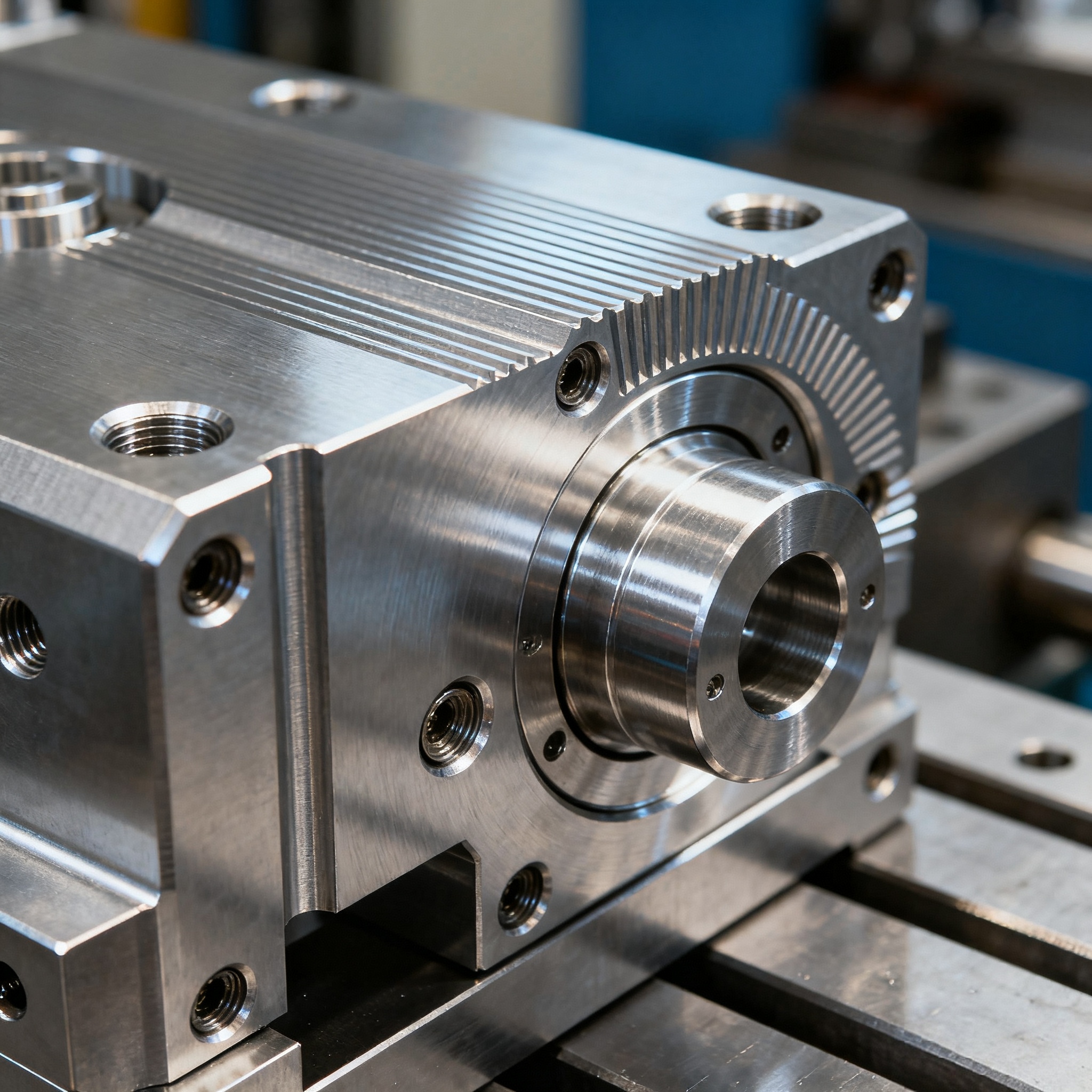

CNC Aluminum Machining: A Precision - Driven Process

CNC machining of aluminum is a highly precise and automated operation that shapes and cuts aluminum into customized components.

Here is a detailed breakdown of the key steps:

Design and Programming

CAD Design:

Start by crafting a detailed 3D model with CAD software, precisely defining all specifications and dimensions.

CNC Programming:

Transform the CAD file into CNC - compatible G - code, which serves as the instruction set for the machine's tool movements to achieve the desired geometry.

Material Preparation

Aluminum Selection:

Select the most suitable aluminum alloy (such as 6061 or 7075) according to application requirements. These alloys are prized for their lightweight properties,

corrosion resistance, and machinability.

Workpiece Setup:

Secure the aluminum block firmly on the CNC machine's worktable using clamps or a vise to ensure stability during machining.

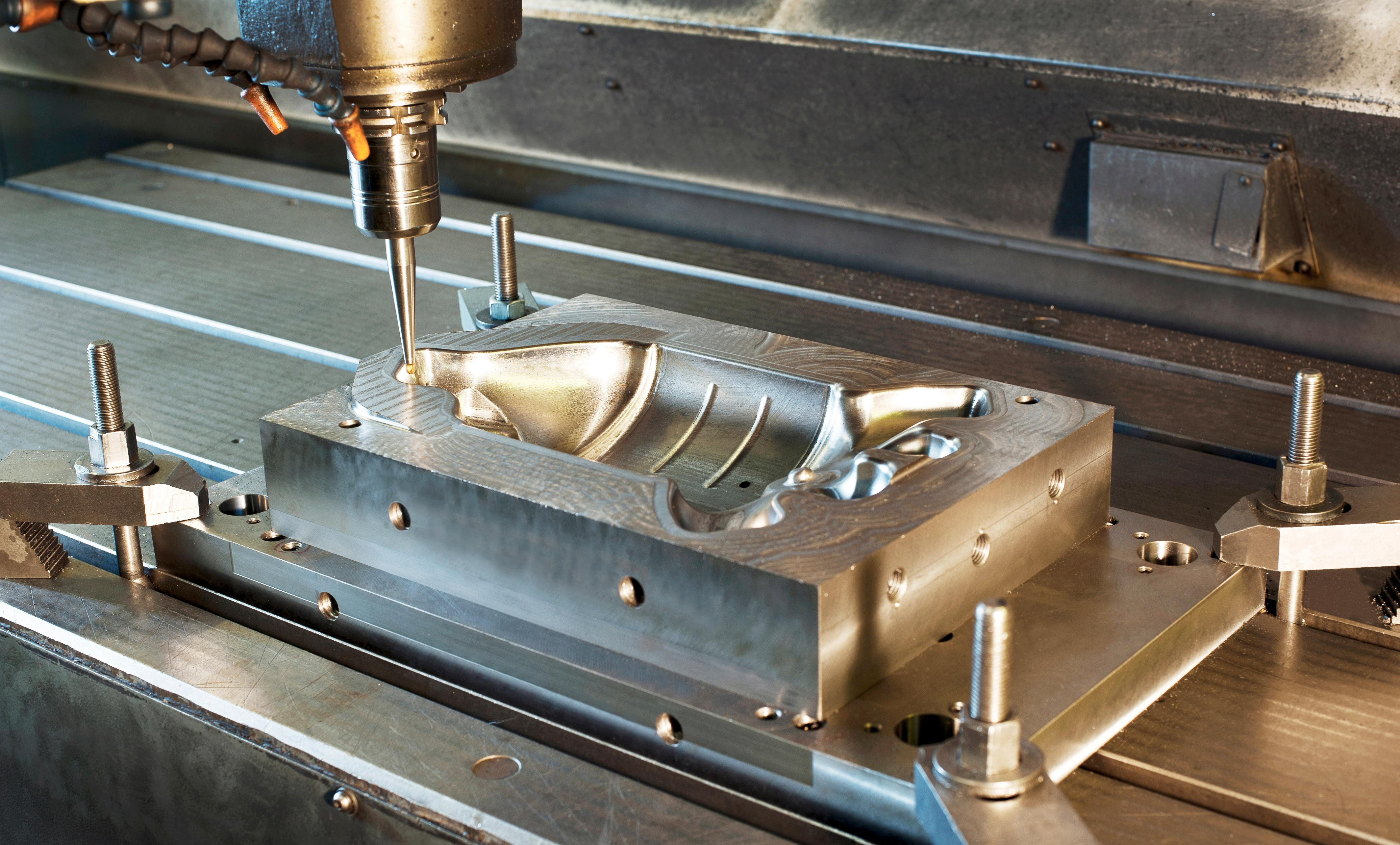

Machining Process

Cutting and Shaping:

Utilize cutting tools like end mills and drills to remove material, following pre - programmed multi - axis (X, Y, Z) paths to create complex shapes.

Cooling:

Apply coolants or lubricants to prevent overheating, minimize tool wear, and enhance the surface finish.

Roughing and Finishing:

First, perform a rough cut to quickly remove excess material.

Then, conduct finishing passes to achieve smooth surfaces and exact dimensions.

Post - Machining Processes

Deburring:

Eliminate sharp edges and burrs to improve part safety and functionality.

Surface Treatments:

Apply treatments such as anodizing, polishing, or powder coating to enhance both the aesthetic appeal and corrosion resistance of the part.

Quality Inspection

Measurement and Testing:

Use precision tools like calipers, micrometers, or Coordinate Measuring Machines (CMM) to inspect the finished part, ensuring it adheres to design specifications

and tolerance requirements.

Advantages of CNC Aluminum Machining

High Precision: Capable of achieving extremely tight tolerances and delivering an outstanding surface quality.

| Type | CNC machining | Entrance size | Customized |