Aluminum CNC Machining: Unleashing Limitless Precision and Innovation

Aluminum CNC Machining: Unleashing Limitless Precision and Innovation

- Customized at your needs

- CNC

- Customized at your needs

- Informations

- Description

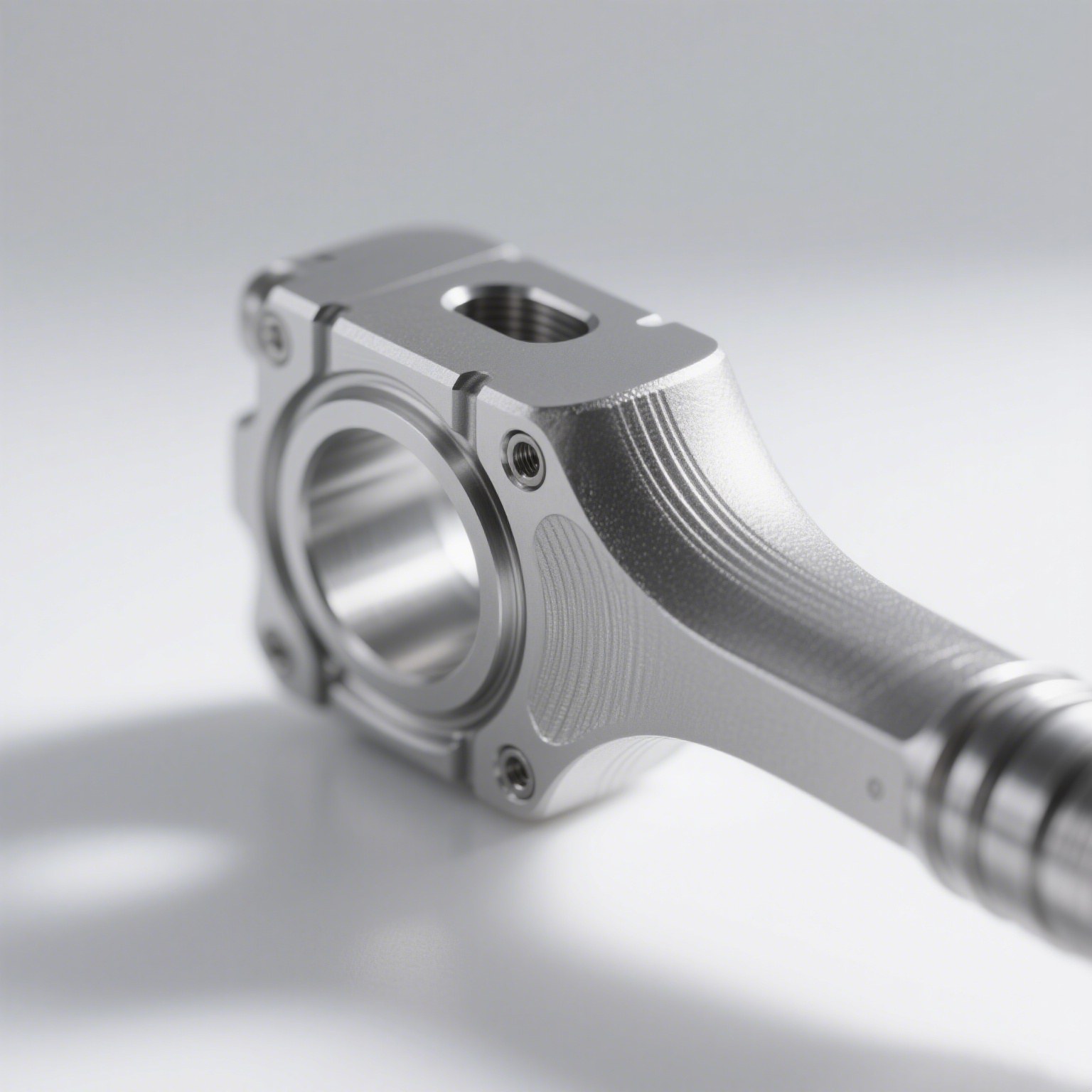

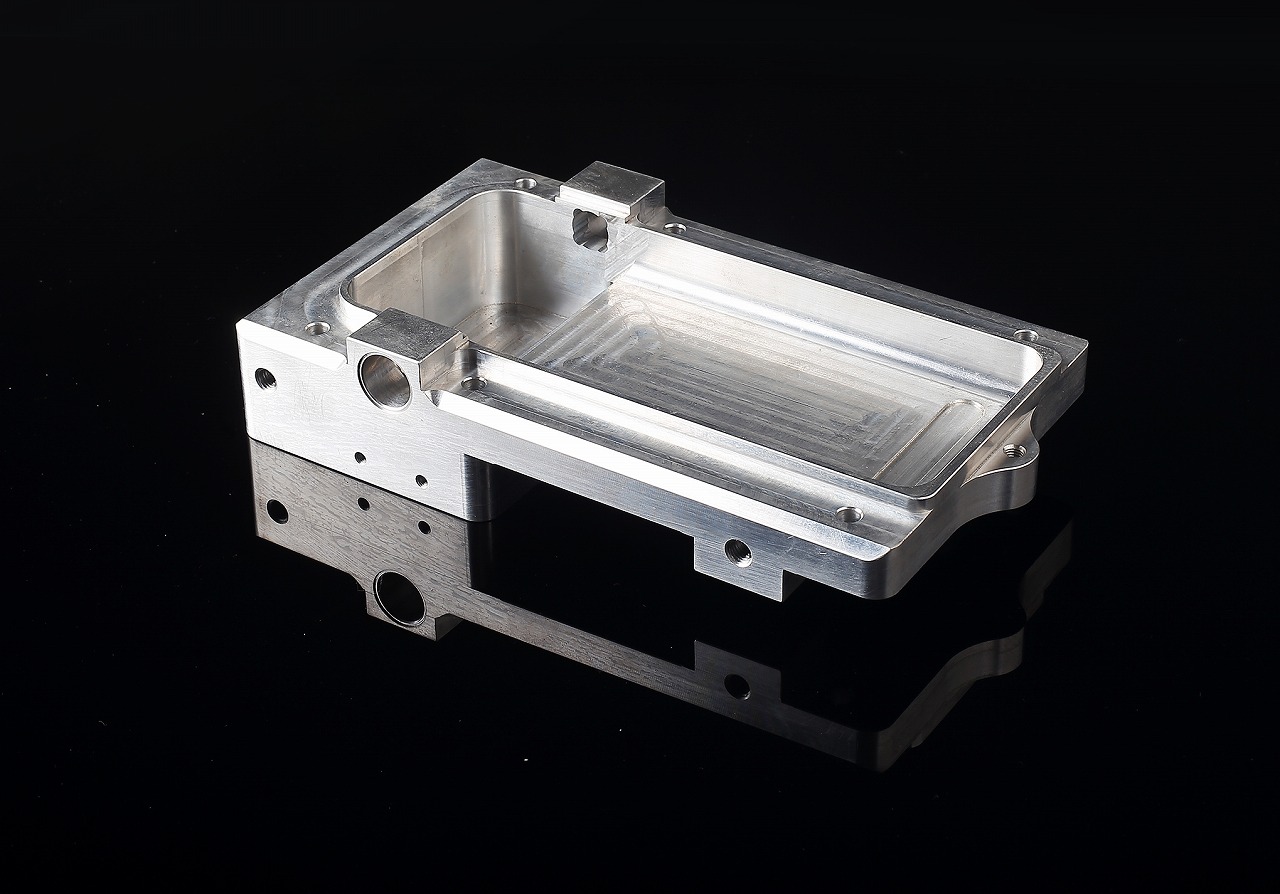

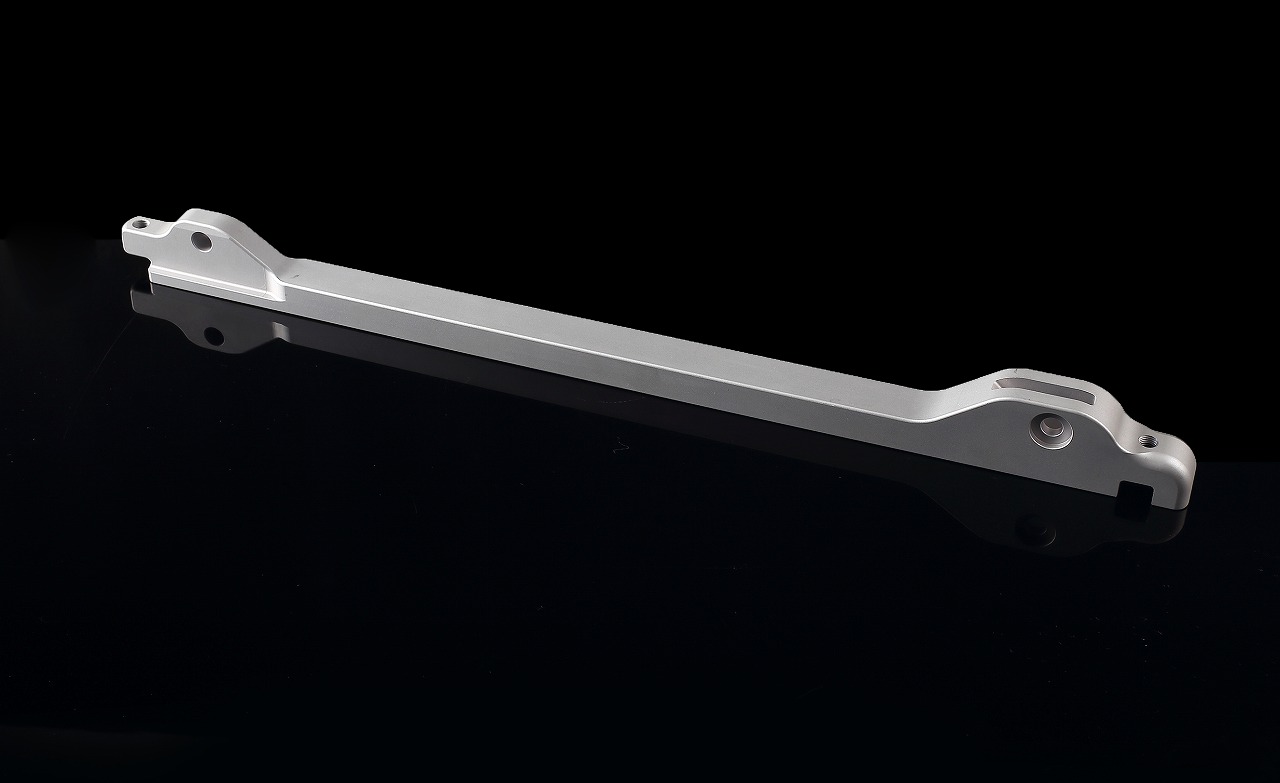

Aluminum CNC Machining: Unleashing Limitless Precision and Innovation

Aluminum CNC Machining: Unleashing Limitless Precision and Innovation

Transcending Traditional CNC Machining

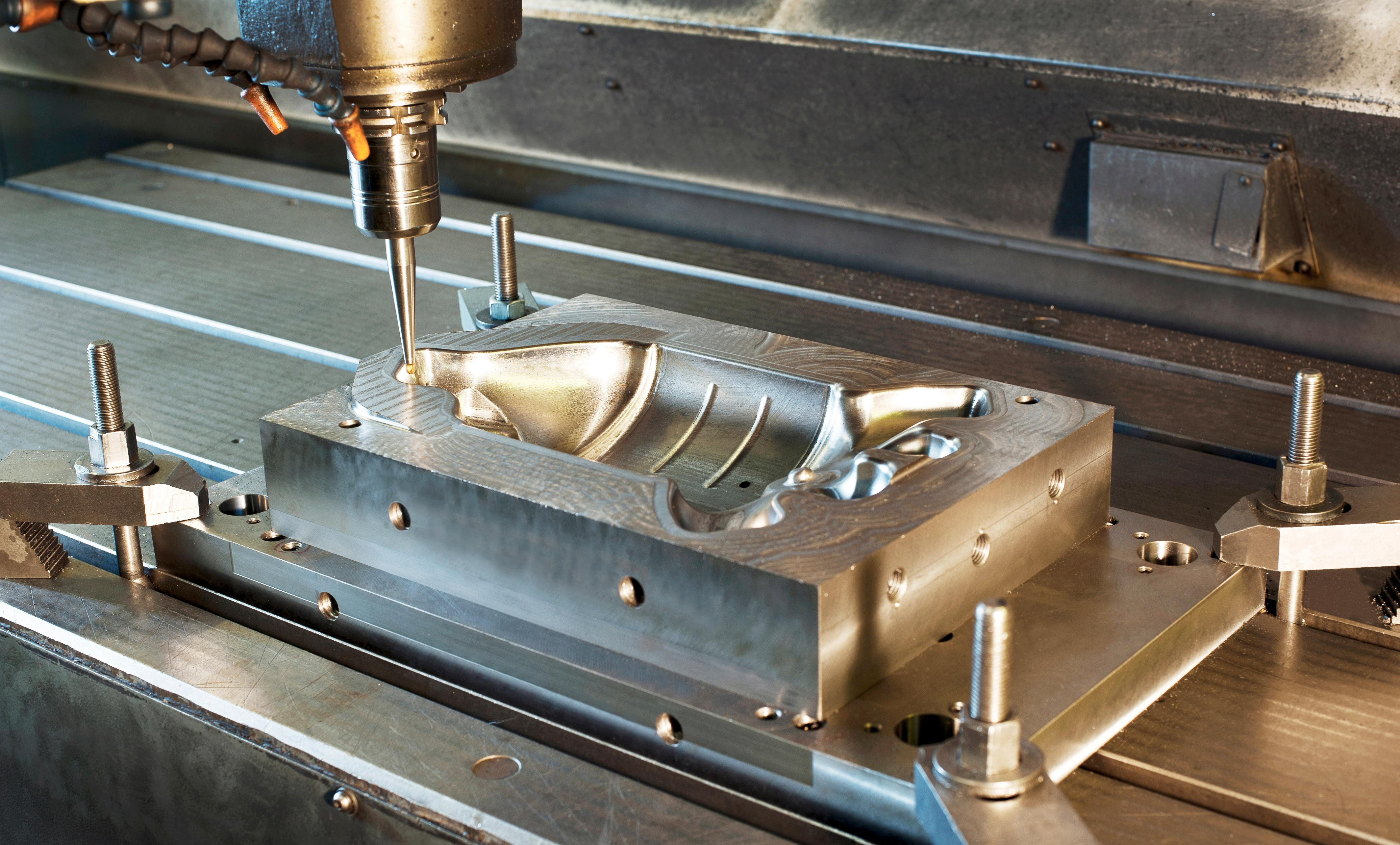

The Cutting - Edge CNC Machining Process

Stage | Operation | Revolutionary Advantages |

1. Digital Twin Creation | Building a virtual replica of the aluminum part using 3D scanning and advanced modeling techniques. This digital twin is used to simulate the entire machining process, predicting potential issues and optimizing toolpaths. | Reduces machining errors by up to 90% and shortens production lead times by 40%, saving both time and costs. |

2. Edge Computing - Driven Machining | Installing edge computing devices on our CNC machines to process data in real - time. These devices analyze sensor data from the machining process, such as temperature, vibration, and tool wear, and adjust machining parameters instantaneously. | Improves machining efficiency by 35% and extends the lifespan of cutting tools by 50%, ensuring consistent and high - quality results. |

3. AI - Assisted Precision Cutting | Employing artificial intelligence algorithms to control the cutting process. The AI system can adapt to the unique characteristics of the aluminum material, adjusting the cutting speed, feed rate, and depth of cut for optimal performance. | Achieves a surface finish accuracy of up to 0.1 microns, far exceeding the standards of traditional CNC machining and enabling the production of ultra - precise components. |

4. Blockchain - Verified Quality Assurance | Recording every step of the machining process on a blockchain, from material sourcing to final inspection. This creates an immutable record of the product's quality and origin. | Enhances product traceability and quality assurance, providing customers with complete confidence in the reliability and authenticity of our machined aluminum components. |

Why Choose Our Aluminum CNC Machining Service?

Innovative Technological Integration: We're at the forefront of CNC machining innovation, seamlessly combining digital twin technology, edge computing, AI, and blockchain to offer solutions that are years ahead of the competition.

Unrivaled Precision: Our advanced machining techniques and real - time optimization ensure that every aluminum component we produce meets the most stringent precision requirements, making us the go - to choice for high - end applications.

Rapid and Flexible Production: With our digital - first approach and optimized machining processes, we can handle both small - batch custom orders and large - scale production runs with speed and flexibility, getting your products to market faster.

Transparent Quality Assurance: The blockchain - based quality verification system provides complete transparency, allowing you to track and verify the quality of your machined aluminum products at every stage of production.

Embrace the Future of Aluminum Machining

Are you ready to take your aluminum products to the next level?

Contact us today! Let's collaborate and explore how our revolutionary Aluminum CNC machining service can transform your ideas into reality. Whether it's a high - precision medical instrument, a cutting - edge automotive part, or a state - of - the - art electronic component, we have the technology, expertise, and passion to make it happen. Step into the future of aluminum machining with us and experience the difference of true innovation!

| Type | CNC | Entrance size | Customized at your needs |