Aluminum Extrusion

The Powerhouse of Manufacturing: Aluminum Parts Extrusion Process

- Customized

- Aluminum Extrusion

- Customized

- Informations

- Description

The Powerhouse of Manufacturing: Aluminum Parts Extrusion Process

The Powerhouse of Manufacturing: Aluminum Parts Extrusion Process

In the intricate web of modern manufacturing, the aluminum parts extrusion process shines as a cornerstone technology. At ShanFeng, we recognize the immense potential of this process and have integrated it as a key step in our comprehensive manufacturing operations.

The Mechanics Behind Aluminum Extrusion

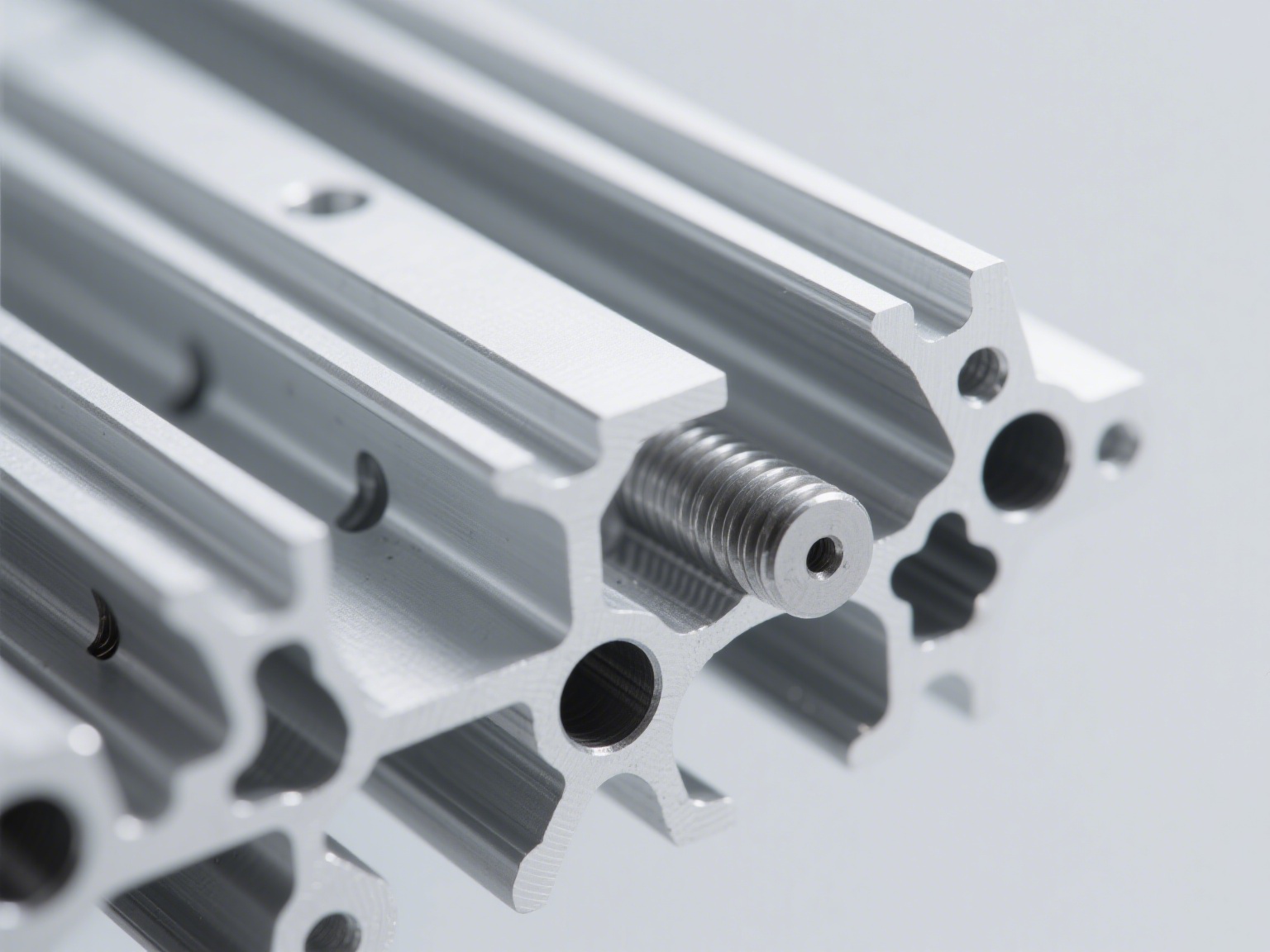

Aluminum extrusion is a fascinating process that involves the transformation of aluminum alloy billets into a multitude of shapes. The fundamental principle is straightforward yet highly effective. A solid aluminum billet, preheated to a state where it is malleable but not molten, is subjected to high pressure within an extrusion press. This pressure forces the aluminum to flow through a die, which is designed with a specific cross-sectional profile. The result is an extrusion that replicates the shape of the die's opening, whether it's a simple rod, a complex multi-chambered profile, or anything in between.

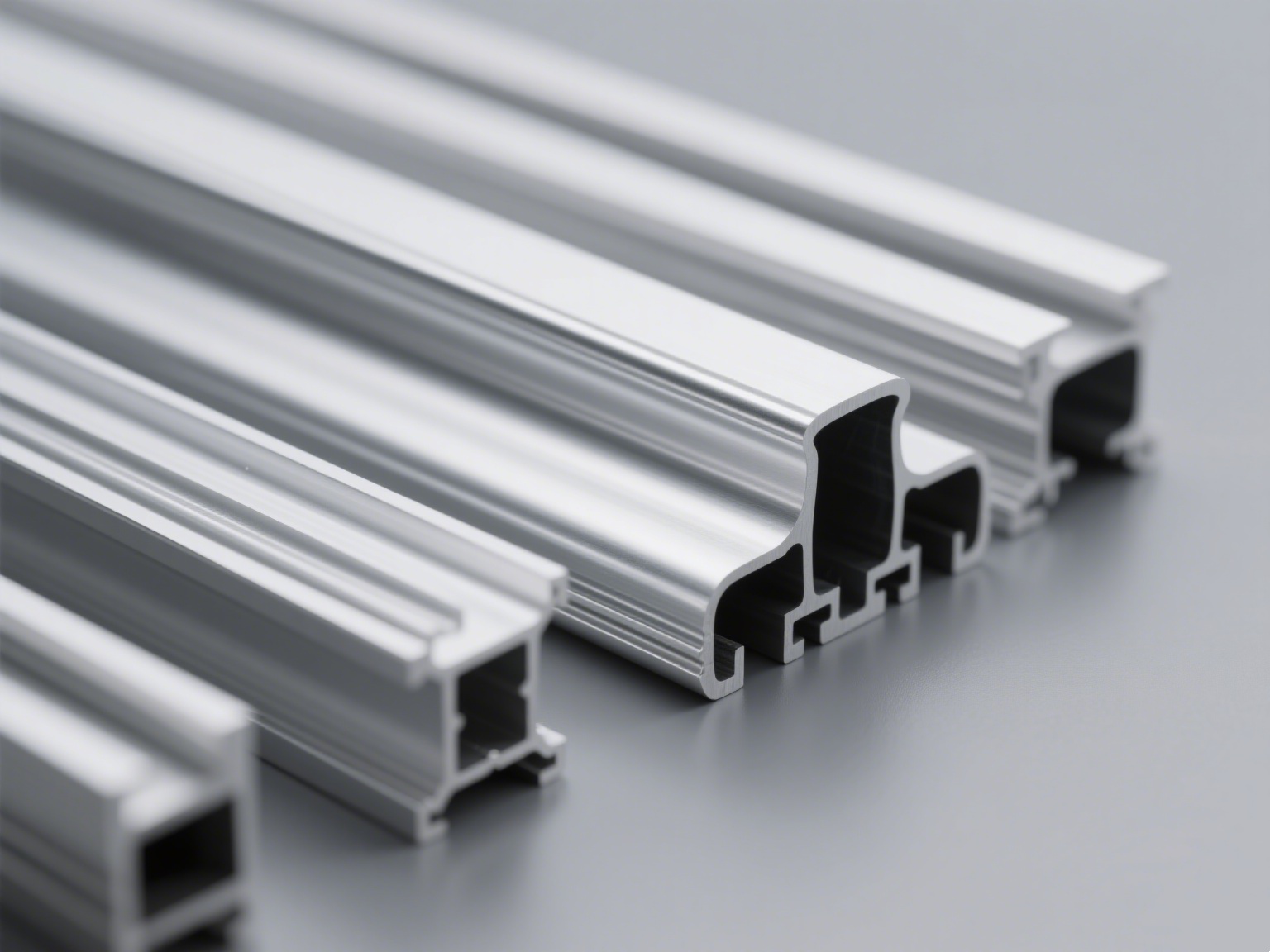

Types of Aluminum Extrusion

Direct Extrusion: This is the most commonly used method in the industry. In direct extrusion, the heated aluminum billet is placed in a stationary container. A ram then applies pressure to push the billet through a fixed die. The simplicity of this process makes it highly efficient for producing a wide range of shapes, especially those with straightforward geometries. It allows for high production speeds and is cost-effective for large-scale manufacturing. For example, in the production of standard aluminum bars and tubes, direct extrusion is often the method of choice.

Indirect Extrusion: In contrast to direct extrusion, indirect extrusion involves keeping the billet stationary while the die moves towards it using a hollow ram. This method offers several advantages, particularly in terms of reducing friction. With less friction, the process can better control the heat generated during extrusion, resulting in a more consistent grain structure and improved mechanical properties of the final product. Indirect extrusion is often preferred for producing more complex and intricate shapes, as it provides greater control over the extrusion process. In the aerospace industry, where precision and high-quality components are crucial, indirect extrusion may be used to create parts with very specific requirements.

Steps in the Aluminum Extrusion Process

Die Creation and Preparation:

The first step in the aluminum extrusion process is the creation or selection of the appropriate die. Dies are typically made from high-quality steel and are precision-machined to the exact specifications of the desired extrusion shape. Before use, the die is preheated to a temperature between 450 - 500 degrees Celsius. This preheating is essential as it helps to ensure smooth and even flow of the aluminum through the die, maximizing the die's lifespan and the quality of the extrusion.

Billet Preparation:

A solid aluminum billet, usually cut from a larger log of alloy material, is then prepared for extrusion. The billet is preheated in an oven to a temperature range of 400 - 500 degrees Celsius. This heating process makes the billet more malleable, allowing it to be easily shaped during the extrusion process. Before loading the billet into the extrusion press, it is carefully inspected to ensure it is free from any defects or contaminants that could affect the quality of the final product.

Extrusion Press Operation:

Once the die and billet are prepared, the billet is loaded into the extrusion press. A lubricant or release agent is applied to both the billet and the extrusion ram to prevent sticking. The hydraulic ram within the press then applies a significant amount of pressure, often up to 15,000 tons, to push the billet through the die. As the aluminum is forced through the die, it takes on the shape of the die's opening and emerges as a continuous extrusion.

Quenching and Cooling:

Immediately after emerging from the die, the extrusion is gripped by a puller and guided along a runout table. As it moves along the table, the extrusion is quenched, which involves rapid cooling. This cooling process can be achieved using a water bath or fans, depending on the specific requirements of the product. Quenching helps to set the shape of the extrusion and improve its mechanical properties.

Cutting and Finishing:

After quenching, the extrusion is first cut to a suitable table length using a hot saw. Since the extrusion has not fully cooled at this stage, cutting with a hot saw helps to minimize any distortion. The cut extrusions are then moved to a cooling table to reach room temperature. To correct any potential twists or deformities, the extrusions are transferred to a stretcher, where they are pulled until they are straight and meet the required specifications. Finally, the extrusions are cut to the exact lengths needed for the final product using a finish saw.

Advantages of Aluminum Extrusion in Manufacturing

Design Flexibility

One of the most significant advantages of aluminum extrusion is its unparalleled design flexibility. The process can create parts with extremely complex shapes that would be difficult or impossible to achieve using other manufacturing methods. This makes it an ideal choice for industries where custom-designed components are required. In the automotive industry, for example, aluminum extrusions can be used to create lightweight yet strong components such as chassis parts, suspension components, and interior trim pieces. The ability to design parts with specific shapes and features allows for better integration within the vehicle, improving performance and aesthetics.

High Precision and Quality

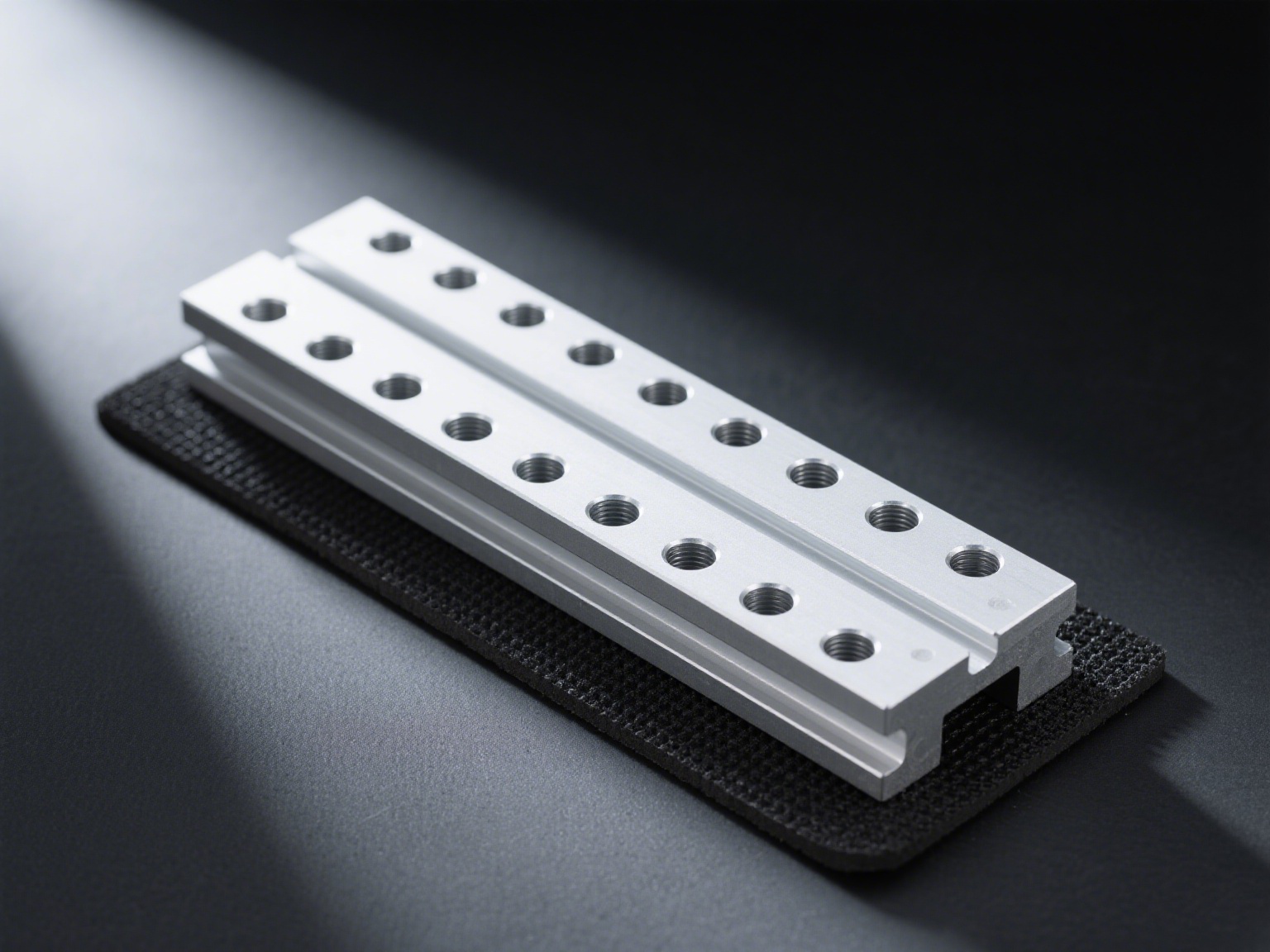

Aluminum extrusion offers a high level of precision, ensuring that the final parts meet tight dimensional tolerances. The consistent flow of aluminum through the die results in a uniform cross-sectional shape along the entire length of the extrusion. This precision is crucial in industries such as electronics, where components need to fit together perfectly. In the production of heat sinks for electronic devices, for instance, the precise dimensions of the extruded aluminum fins are essential for efficient heat dissipation. Additionally, the surface finish of extruded aluminum parts is often very good, reducing the need for extensive post-processing. This not only saves time but also costs, as fewer machining or finishing operations are required.

Material Efficiency

The aluminum extrusion process is highly material-efficient. Since the aluminum is simply forced through the die, there is minimal material waste compared to other manufacturing methods that involve cutting, machining, or casting. This not only reduces the cost of raw materials but also makes the process more environmentally friendly. Moreover, aluminum is a highly recyclable material, and recycled aluminum can be used in the extrusion process without significant loss of quality. This further enhances the sustainability of the aluminum extrusion process.

Cost-Effectiveness

In mass production scenarios, aluminum extrusion proves to be a cost-effective solution. Once the initial investment in the die is made, the cost per unit for extruded parts can be relatively low. The high production speeds achievable with the extrusion process, especially in direct extrusion for simpler shapes, contribute to efficient manufacturing. Additionally, the reduced need for post-processing and the material efficiency mentioned earlier further enhance the cost-effectiveness of the process. This makes aluminum extrusion an attractive option for industries such as construction, where large quantities of parts are required. In the construction of window frames and curtain walls, aluminum extrusions are widely used due to their cost-effectiveness, durability, and aesthetic appeal.

In summary, the aluminum parts extrusion process is a powerful and versatile manufacturing technique that offers numerous benefits. At ShanF, we leverage the capabilities of this process to deliver high-quality aluminum parts that meet the diverse needs of our clients across a wide range of industries. Whether it's a small, precision component or a large, complex structure, our expertise in aluminum extrusion allows us to provide innovative solutions that combine performance, quality, and cost-effectiveness.

| Type | Aluminum Extrusion | Entrance size | Customized |