Aluminum Extrusion Parts

Ever wondered how those sleek, perfectly shaped aluminum parts are made? Enter the world of aluminum...

- Customized

- Aluminum Extrusion

- Customized

- Informations

- Description

Ever wondered how those sleek, perfectly shaped aluminum parts are made? Enter the world of aluminum extrusion.

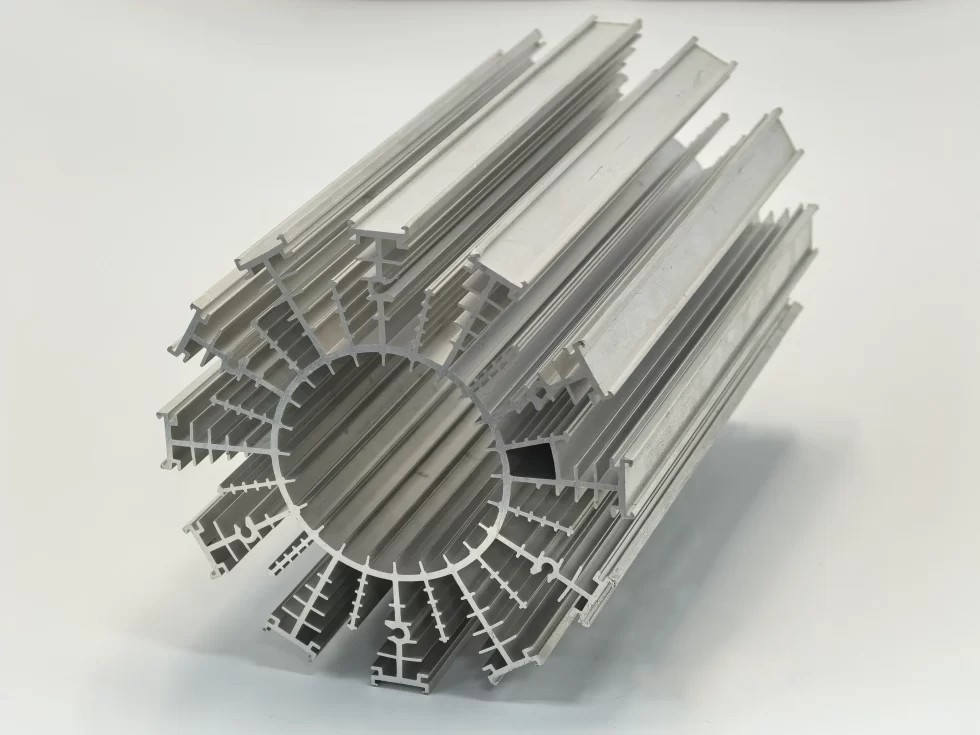

The Magic of Aluminum Extrusion

Ever wondered how those sleek, perfectly shaped aluminum parts are made? Enter the world of aluminum extrusion!

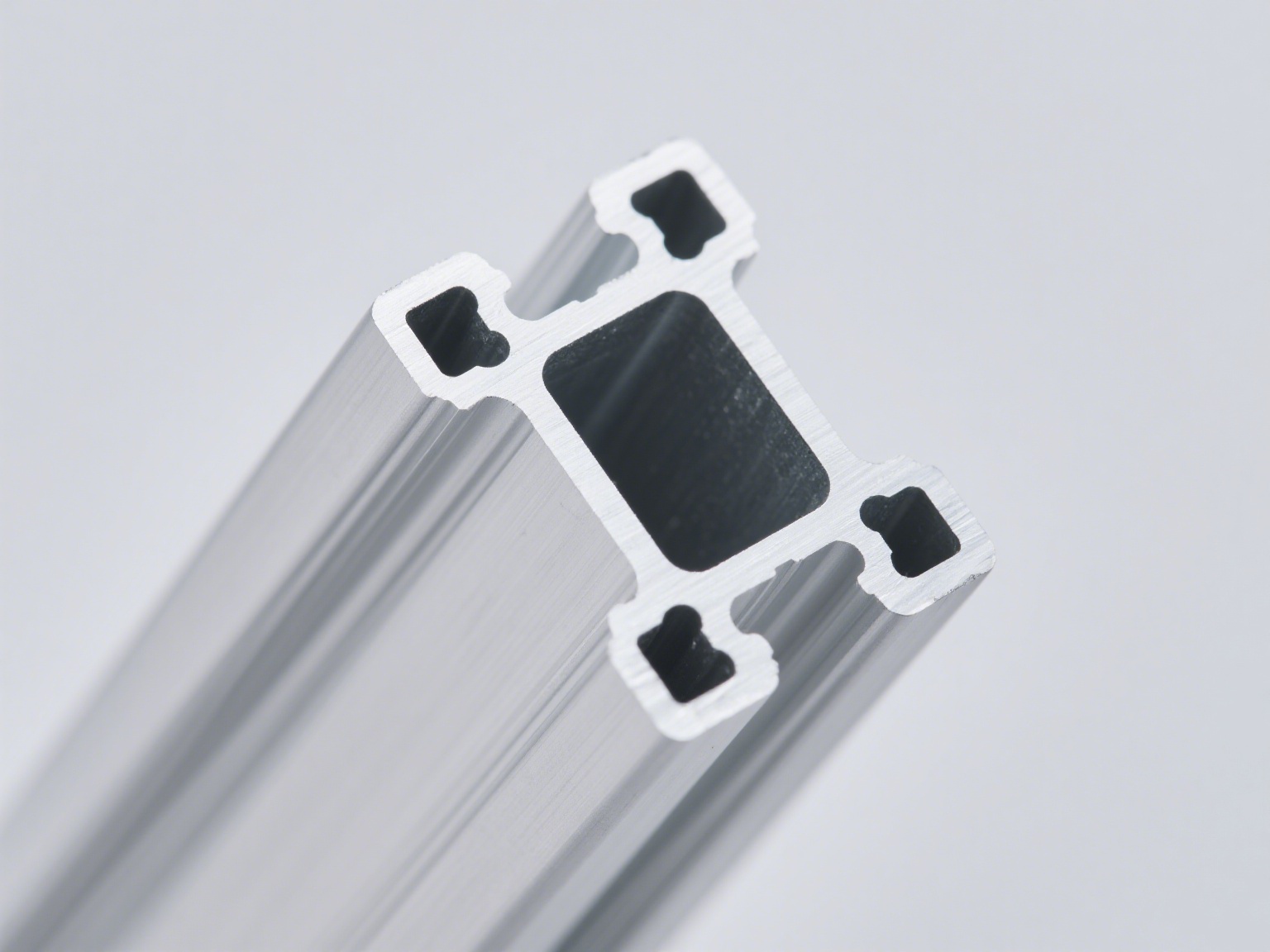

This process involves pushing heated aluminum through a die, like play - dough through a fun - shaped cutter, but on an industrial scale. The result? Endless possibilities in design! From the sturdy frames of our windows and doors to the lightweight components in cars and planes, aluminum extrusion is everywhere.

Why Aluminum?

Lightweight yet Strong:

It's about a third the weight of steel but can be alloyed to be incredibly tough. This makes it perfect for applications where weight matters, like in aerospace.

Corrosion - Resistant:

Aluminum naturally forms a protective oxide layer, meaning it can withstand the elements, whether it's a salty sea breeze or a rainy day.

Cost - Effective:

Mass - producing complex shapes is a breeze with extrusion, keeping costs down for high - volume projects.

Where Do We See It?

Construction:

Creating beautiful, durable window and door frames, as well as structural components.

Automotive:

Used in car bodies and parts to reduce weight and improve fuel efficiency.

Electronics:

For heat sinks, helping our devices stay cool.

Next time you see an aluminum product, take a moment to appreciate the magic of aluminum extrusion.

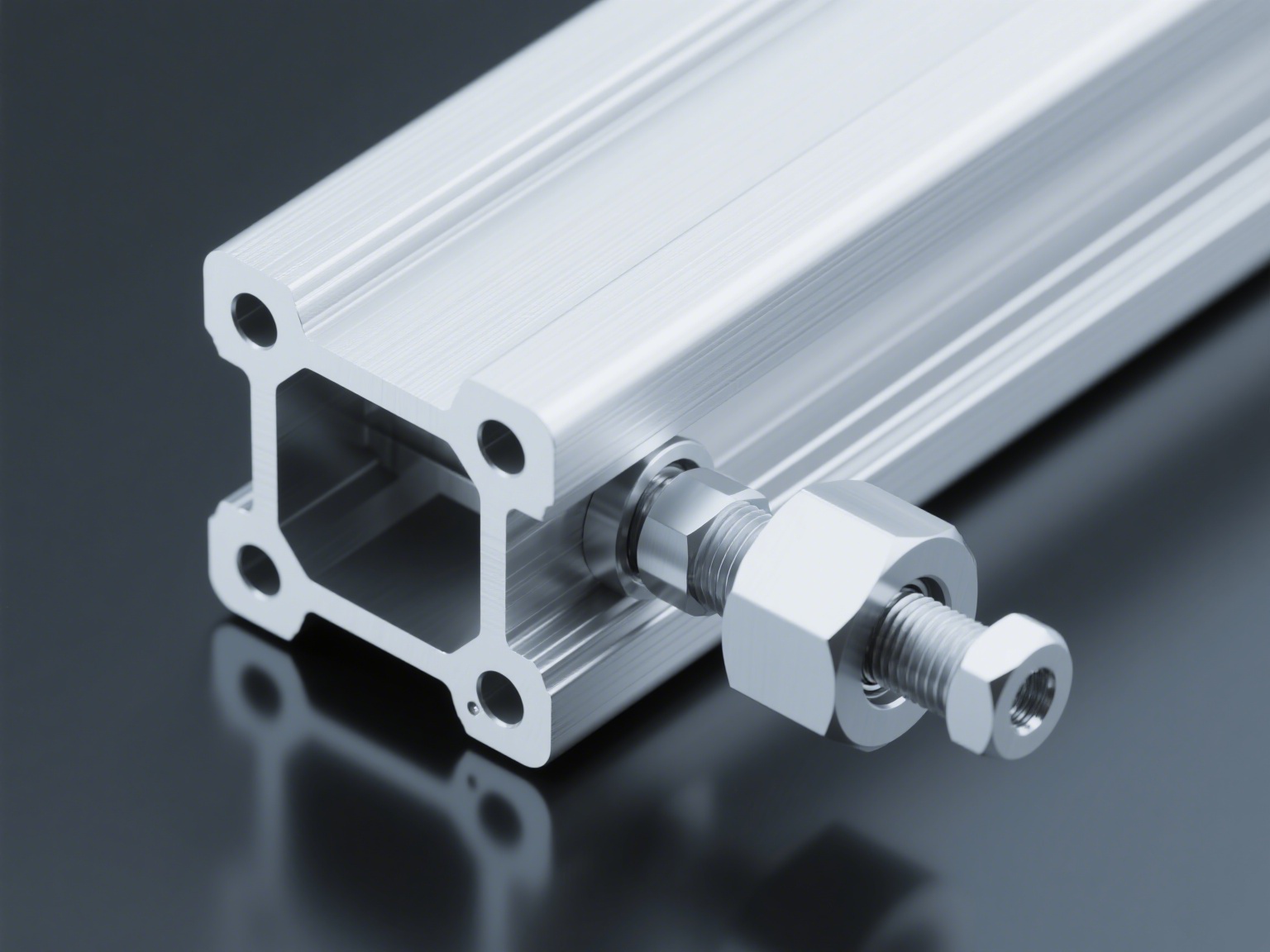

| Type | Aluminum Extrusion | Entrance size | Customized |