Aluminum Forging: Material Innovations, Technological Leaps and Specialized Applications

Aluminum Forging: Material Innovations, Technological Leaps and Specialized Applications

- Customized at your need

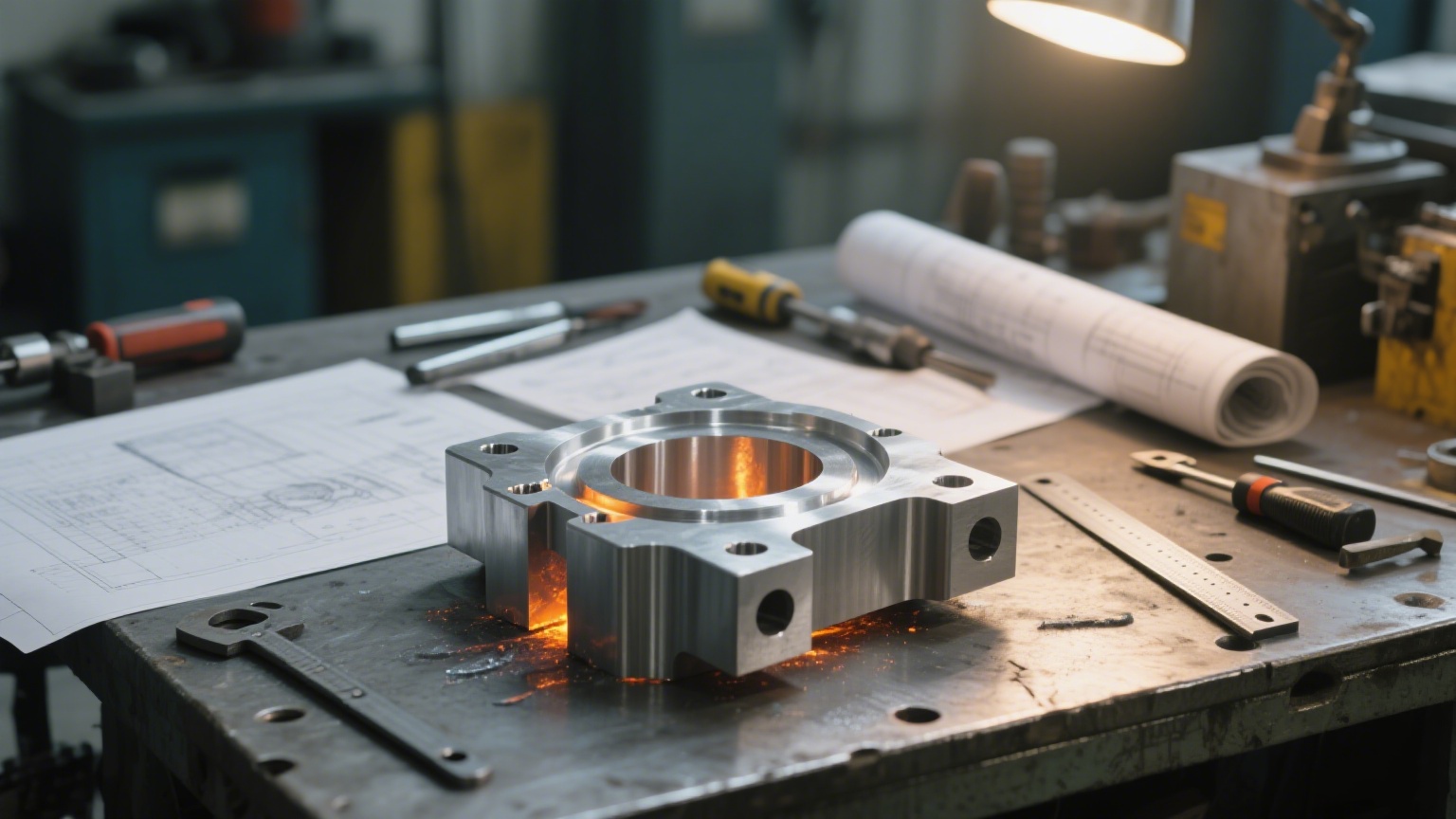

- Aluminum Parts Forging

- Customized based on your drawings

- Informations

- Description

Aluminum Forging: Material Innovations, Technological Leaps and Specialized Applications

Aluminum Forging: Material Innovations, Technological Leaps and Specialized Applications

Revolutionary Aluminum Alloys: Enhancing Performance

Alloy | Tensile Strength | Yield Strength | Fatigue Strength (10^7 cycles) | Density |

7085-T7452 | 560 MPa ± 6 MPa | 510 MPa ± 5 MPa | 220 MPa ± 4 MPa | 2.81 g/cm³ ± 0.01 g/cm³ |

6061-T6 | 310 MPa ± 5 MPa | 276 MPa ± 4 MPa | 110 MPa ± 3 MPa | 2.70 g/cm³ ± 0.01 g/cm³ |

2024-T3 | 470 MPa ± 5 MPa | 325 MPa ± 4 MPa | 130 MPa ± 3 MPa | 2.78 g/cm³ ± 0.01 g/cm³ |

Technological Breakthroughs: Forging the Future

Hydrostatic Forging: This technique involves surrounding the billet with a high-pressure fluid, typically oil, which applies uniform pressure to the metal. Unlike traditional forging, where pressure is applied from specific directions, hydrostatic forging ensures that the metal flows evenly, allowing for the production of components with intricate geometries and thin walls. This process is especially valuable in the production of medical devices, where precision and complex shapes are critical. For example, hydrostatically forged aluminum components are used in MRI machines, where their non-magnetic properties and precision fit are essential.

Robotic Forging Cells: Automation has made its way into aluminum forging with the introduction of robotic forging cells. These cells combine robotic arms with forging presses, enabling seamless material handling, precise positioning of the billet in the die, and real-time adjustments based on sensor data. Robotic cells not only improve productivity by reducing cycle times but also enhance safety by minimizing human interaction with high-temperature and high-pressure equipment. In high-volume production facilities, robotic forging cells have increased output by up to 30% while reducing labor costs by 25%.

Specialized Applications: Niche Markets and Unique Solutions

Marine Industry: The marine environment is highly corrosive, making corrosion resistance a key requirement for components. Forged aluminum alloys such as 5083-H116 offer excellent resistance to saltwater corrosion, making them ideal for marine applications. Components like propeller shafts, hull fittings, and deck hardware made from forged 5083-H116 provide long-term durability, reducing maintenance costs and extending the service life of marine vessels.

Sports Equipment: High-performance sports equipment requires a combination of strength, lightness, and impact resistance. Forged aluminum is used in the production of bicycle frames, golf club heads, and ski bindings. For example, premium bicycle manufacturers use forged aluminum frames that are not only lightweight but also offer superior stiffness, enhancing the rider’s performance and comfort. Golf club heads made from forged aluminum provide better energy transfer, resulting in longer drives and more accurate shots.

Space Exploration: The extreme conditions of space, including high radiation, extreme temperatures, and vacuum, demand components that are both lightweight and extremely durable. Forged aluminum alloys are used in the construction of satellite structures, rocket components, and lunar rovers. The low density of aluminum reduces the launch weight, while its high strength ensures that components can withstand the rigors of space travel.

Environmental Impact: Going Beyond Recycling

Conclusion: Expanding Horizons

| Type | Aluminum Parts Forging | Entrance size | Customized based on your drawings |