Aluminum Forging: Design Optimization, Digital Integration and Emerging Energy Applications

Aluminum forging is not just a manufacturing process but a dynamic field where design ingenuity, digital technologies, and evolving energy needs converge to create unprecedented possibilities. As industries seek more efficient, durable, and customized solutions, aluminum forging continues to adapt and innovate, pushing the boundaries of what can be achieved.

Design Optimization: Tailoring Components for Maximum Efficiency

Modern design techniques are revolutionizing how aluminum forged components are conceptualized and engineered, with a focus on optimizing performance while minimizing weight and material usage. Topology optimization is one such technique that uses algorithms to generate the most efficient component shape based on specific load conditions and constraints. By removing material from non-critical areas, topology optimization results in components that are lighter yet stronger than traditionally designed parts.

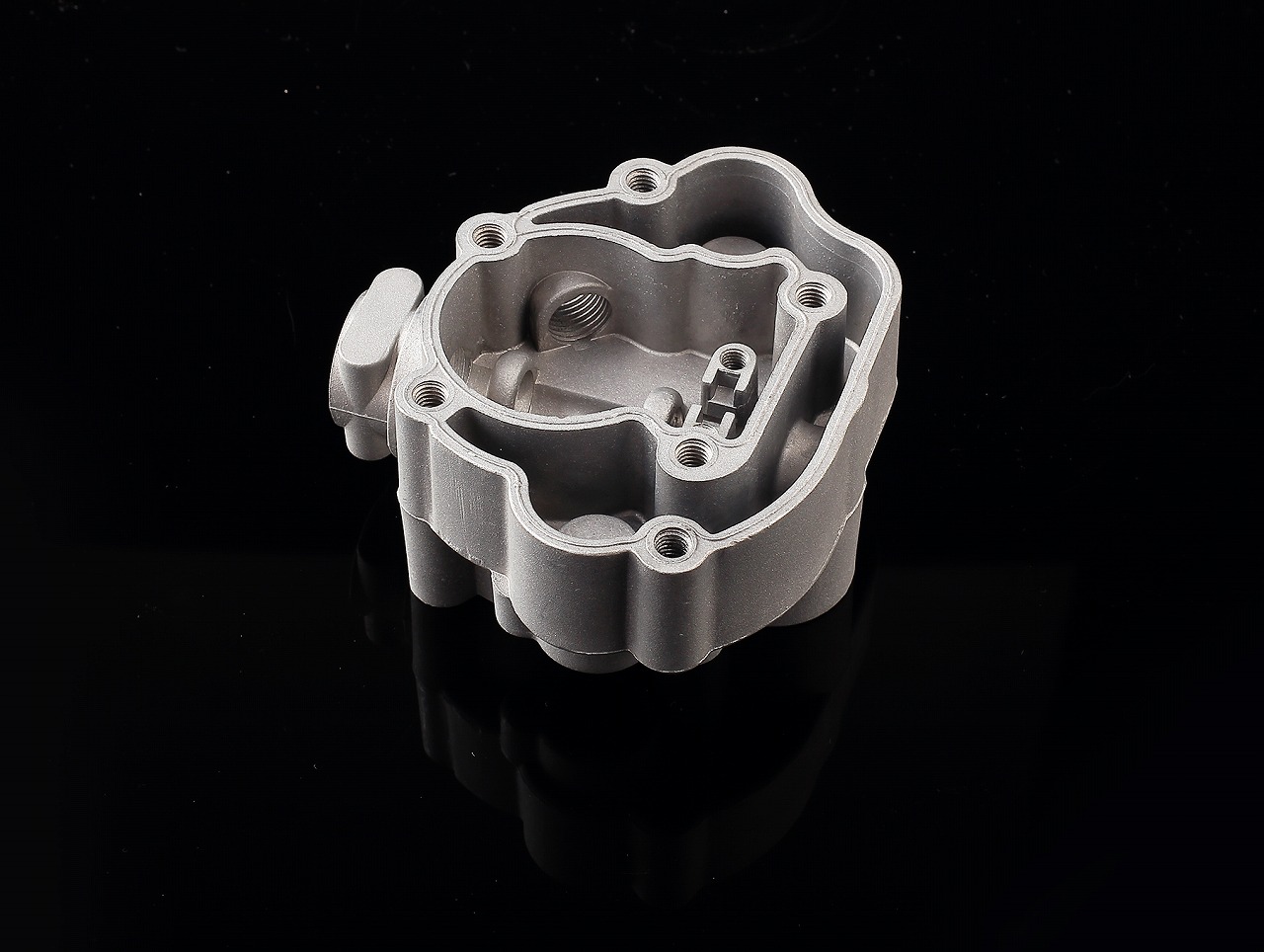

Here’s a comparison of a traditionally designed and topology-optimized aluminum forged component for an industrial pump:

Design Aspect | Traditional Design | Topology-Optimized Design |

Weight | 2.5 kg ± 0.1 kg | 1.8 kg ± 0.08 kg |

Material Usage | 3.2 kg ± 0.1 kg | 2.1 kg ± 0.08 kg |

Stiffness | 120 N/mm ± 5 N/mm | 135 N/mm ± 4 N/mm |

Production Time | 45 minutes ± 2 minutes | 38 minutes ± 1 minute |

The topology-optimized component offers a 28% reduction in weight and a 34% reduction in material usage while increasing stiffness by 12.5%. This not only improves the efficiency of the pump but also reduces transportation costs and energy consumption during operation.

Another design innovation is multi-material forging, where aluminum is combined with other materials such as carbon fiber composites or high-strength steel in a single forging process. This allows for components that leverage the unique properties of each material. For example, a multi-material forged aluminum and carbon fiber composite drive shaft for a sports car can provide the strength of steel, the lightness of aluminum, and the vibration-damping properties of carbon fiber, resulting in a superior performance component.

Digital Integration: Smart Forging for Precision and Predictability

The integration of digital technologies is transforming aluminum forging into a smart, data-driven process, enhancing precision, reducing errors, and enabling predictive maintenance. Digital twins are virtual replicas of the forging process and the resulting component, created using real-time data from sensors embedded in the forging equipment. These digital twins allow engineers to simulate and analyze the forging process in detail, predict how the component will perform under different conditions, and identify potential issues before they occur.

In one case study, a leading aluminum forging manufacturer implemented digital twins for their aerospace component production line. The results were impressive:

Blockchain technology is also making inroads into aluminum forging, providing a secure and transparent way to track the entire lifecycle of a forged component. From the source of the aluminum billet to the forging process parameters, quality control results, and end-use application, every piece of data is recorded on a blockchain. This not only ensures traceability but also helps in identifying counterfeit components, which is crucial in industries like aerospace and defense.

Emerging Energy Applications: Powering the Green Transition

As the world shifts towards renewable energy, aluminum forging is playing a vital role in the development of efficient and reliable energy systems:

Solar Power: Solar tracking systems require components that can withstand constant movement and exposure to the elements. Forged aluminum components such as gearboxes and structural supports offer the necessary durability and corrosion resistance. For example, forged aluminum gearboxes for solar trackers have a service life of 25 years ± 2 years, compared to 15 years ± 2 years for cast iron gearboxes, reducing the need for replacements and lowering the overall cost of solar energy systems.

Hydrogen Energy: Hydrogen fuel cells require components that are lightweight, corrosion-resistant, and compatible with hydrogen. Forged aluminum alloys like 6061-T6 are used in the production of hydrogen storage tanks and fuel cell bipolar plates. The high strength of forged 6061-T6 allows for thinner tank walls, increasing storage capacity while maintaining safety. Bipolar plates made from forged aluminum offer excellent electrical conductivity and corrosion resistance, improving the efficiency of fuel cells by up to 10% ± 1%.

Geothermal Energy: Geothermal power plants operate in harsh environments with high temperatures and pressures. Forged aluminum components such as valves and heat exchangers are used in these plants due to their high-temperature strength and corrosion resistance. Forged aluminum valves can operate at temperatures up to 200°C ± 5°C without significant degradation, ensuring reliable performance in geothermal applications.

Conclusion: Forging a Sustainable and Innovative Future

Aluminum forging is at the forefront of manufacturing innovation, driven by design optimization, digital integration, and its role in the green energy transition. The ability to create lightweight, high-performance, and customized components is making aluminum forging indispensable in a wide range of industries.

As digital technologies continue to advance and the demand for sustainable energy solutions grows, aluminum forging will undoubtedly play an even more critical role. Whether through topology optimization, multi-material forging, or integration with blockchain and digital twins, aluminum forging is poised to shape a more efficient, sustainable, and innovative future.

|

Type

|

Aluminum Parts Forging |

Entrance size

|

Customized based on your drawings |

![]()