Aluminum Forging: Market Dynamics, Emerging Trends and Quality Excellence

Aluminum Forging: Market Dynamics, Emerging Trends and Quality Excellence

- Customized at your need

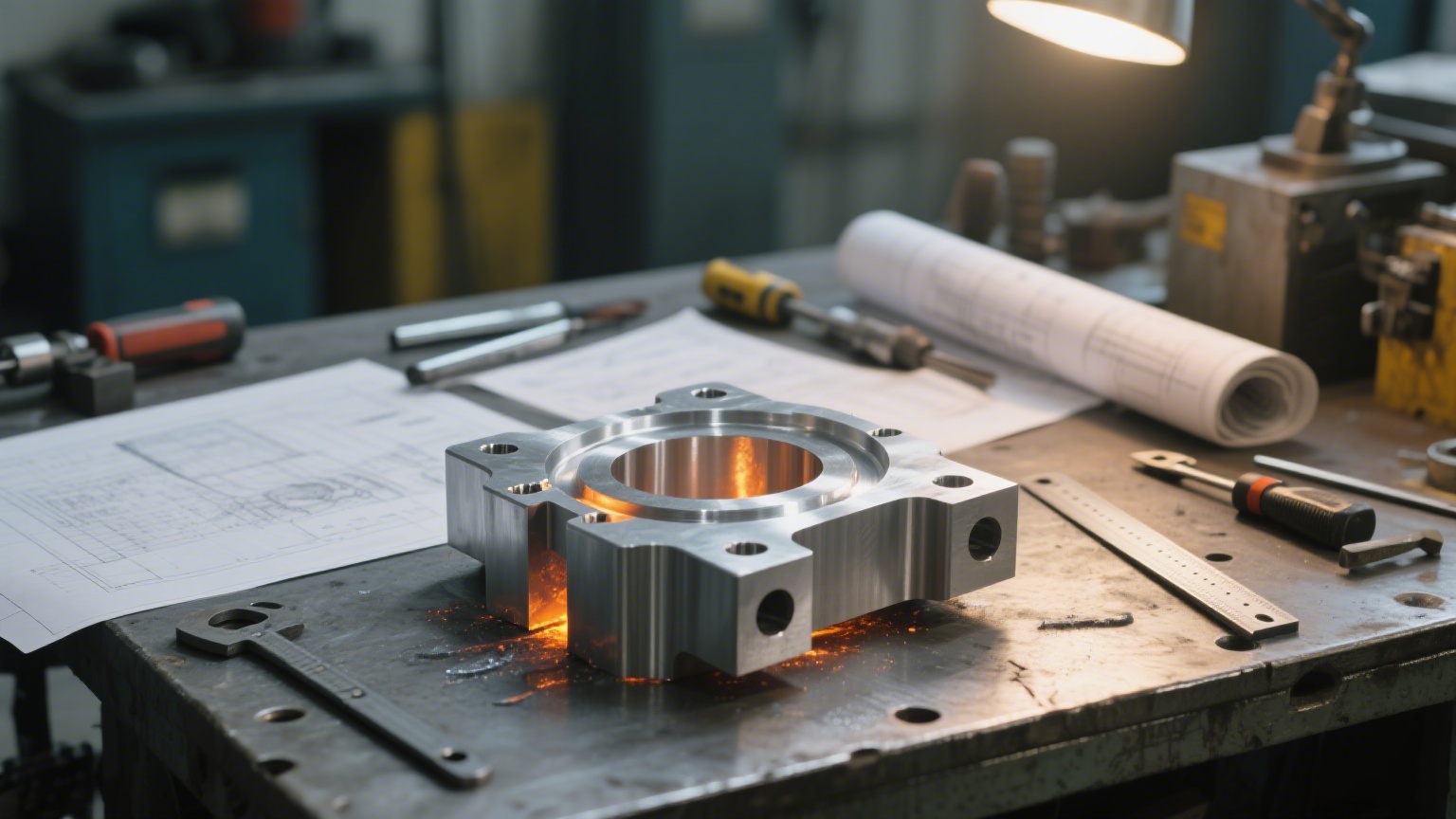

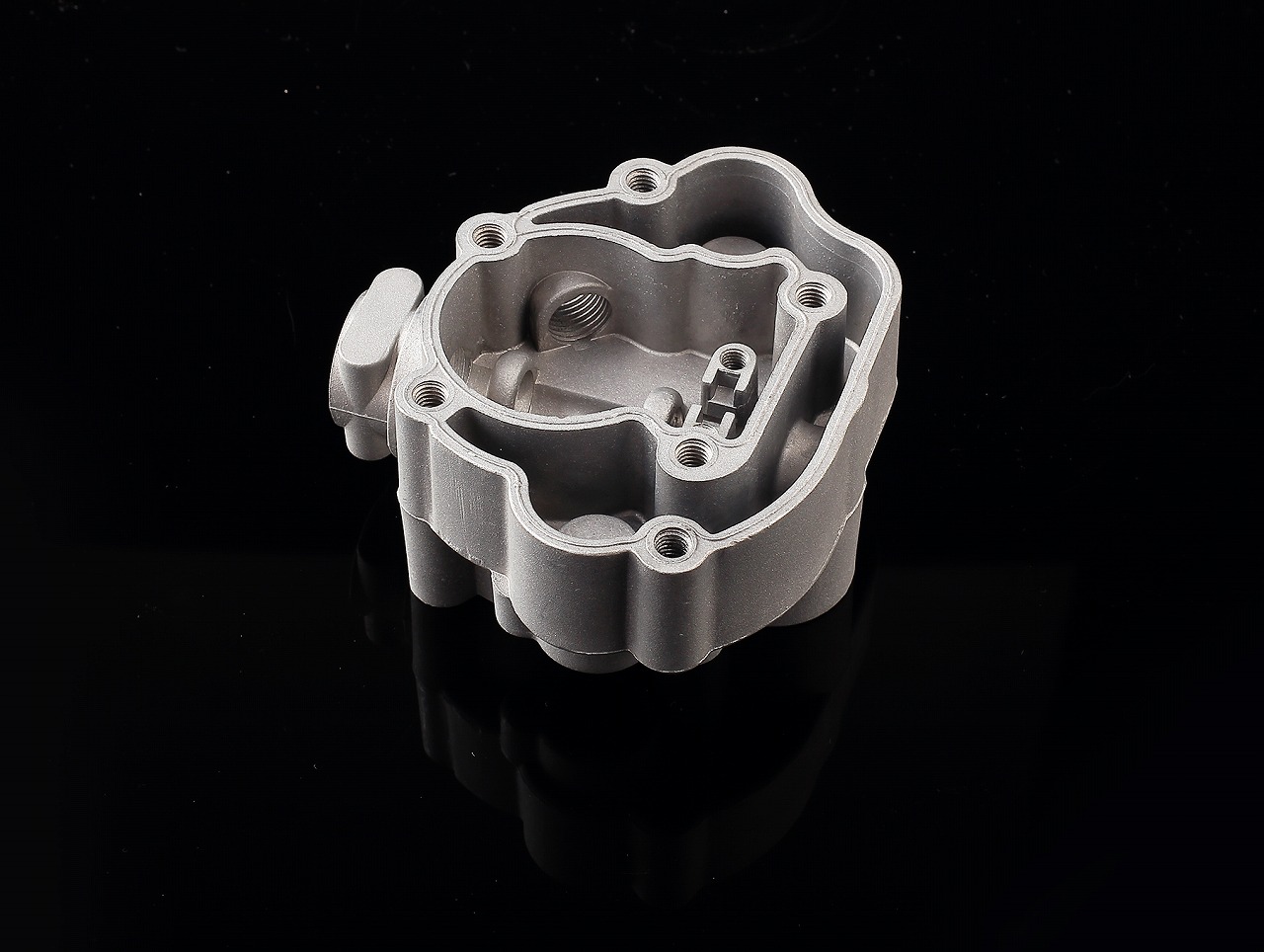

- Aluminum Parts Forging

- Customized based on your drawings

- Informations

- Description

Aluminum Forging: Market Dynamics, Emerging Trends and Quality Excellence

Aluminum Forging: Market Dynamics, Emerging Trends and Quality Excellence

Aluminum forging, a cornerstone of modern manufacturing, is not only defined by its technical prowess but also by its dynamic market presence and continuous evolution. As industries worldwide strive for higher performance, lower costs, and greater sustainability, aluminum forging has emerged as a key enabler, driving growth and innovation across the globe.

Market Growth and Regional Dominance: A Global Snapshot

The global aluminum forging market has been experiencing steady growth, fueled by increasing demand from key industries. Here's a breakdown of the market size and growth projections by region:

Region | Market Size (2024) | Projected CAGR (2024-2030) | Key Growth Drivers |

Asia-Pacific | \(12.5 billion ± \)0.3 billion | 6.8% ± 0.2% | Booming automotive and aerospace sectors in China and India |

North America | \(8.2 billion ± \)0.2 billion | 5.5% ± 0.1% | Advancements in defense and aerospace technologies |

Europe | \(7.8 billion ± \)0.2 billion | 5.2% ± 0.1% | Focus on electric vehicle production and sustainability |

Latin America | \(2.1 billion ± \)0.1 billion | 4.9% ± 0.1% | Growing automotive manufacturing industry |

Middle East & Africa | \(1.5 billion ± \)0.1 billion | 4.5% ± 0.1% | Infrastructure development and aerospace investments |

The Asia-Pacific region leads the market, driven by the rapid expansion of the automotive industry in countries like China, where electric vehicle production is surging. The region's focus on lightweight materials to meet stringent emission standards has propelled the demand for aluminum forging components. In North America, the aerospace sector's continuous innovation, coupled with defense modernization programs, is a major growth driver, with companies investing heavily in advanced forging technologies to produce next-generation aircraft components.

Emerging Trends: Beyond Traditional Applications

While aluminum forging has long been a staple in aerospace and automotive, new trends are expanding its reach into previously untapped areas. One such trend is the adoption of aluminum forging in renewable energy systems. Wind turbines, for example, require components that can withstand harsh environmental conditions while remaining lightweight. Forged aluminum hubs and connecting parts offer the perfect combination of strength and corrosion resistance, contributing to the efficiency and longevity of wind energy systems.

Another emerging application is in consumer electronics. As devices become more powerful and compact, the demand for high-strength, lightweight components is on the rise. Aluminum forging is being used to produce structural parts for laptops, tablets, and even virtual reality headsets, where durability and weight are critical factors. For instance, some high-end laptop manufacturers now use forged aluminum chassis, which provide superior protection against drops and impacts compared to plastic or cast aluminum alternatives.

Advanced Quality Control: Ensuring Perfection

Quality control is paramount in aluminum forging, where even the smallest defect can compromise the performance of a component. Advanced non-destructive testing (NDT) techniques are now being employed to ensure the highest standards of quality. Phased array ultrasonic testing (PAUT) is one such technique, which uses multiple ultrasonic probes to create detailed images of the internal structure of forged components. This allows inspectors to detect flaws such as cracks, voids, and inclusions with unprecedented accuracy, ensuring that only defect-free parts reach the market.

In addition to NDT, real-time process monitoring has become a standard practice in modern aluminum forging facilities. Sensors placed throughout the forging press and die collect data on temperature, pressure, and deformation rates, which is then analyzed in real-time using advanced software. This allows operators to make immediate adjustments to the process, ensuring that each component meets the required specifications. The data collected also provides valuable insights for process optimization, helping manufacturers reduce waste and improve efficiency over time.

Cost-Effectiveness: Balancing Performance and Affordability

While aluminum forging offers superior performance, it is also increasingly being recognized for its cost-effectiveness, especially in high-volume production. The initial tooling costs for forging can be higher than those for casting or machining, but the savings in material and labor costs over time more than make up for this investment. For example, the forging process produces near-net-shape components, reducing the need for expensive secondary machining operations. This not only saves time but also reduces material waste, lowering overall production costs.

Furthermore, the long service life of forged aluminum components translates to lower maintenance and replacement costs for end-users. In the automotive industry, for example, the use of forged aluminum suspension components can reduce the frequency of replacements, leading to significant cost savings over the lifetime of a vehicle.

Conclusion: A Bright Future Ahead

Aluminum forging is a dynamic and evolving field, driven by technological advancements, changing market demands, and a commitment to quality and sustainability. From its growing market presence in Asia-Pacific to its emerging applications in renewable energy and consumer electronics, aluminum forging is poised to play an even more significant role in shaping the future of manufacturing.

As manufacturers continue to innovate and optimize the forging process, we can expect to see even higher performance components, lower production costs, and a wider range of applications. Whether in the sky, on the road, or in our daily lives, aluminum forging will continue to be a key enabler of progress, delivering strength, precision, and value to industries and consumers alike.

| Type | Aluminum Parts Forging | Entrance size | Customized based on your drawings |

Get the latest prices? We will respond as soon as possible (within 12 hours)