A Comprehensive Solution for Metal Surface Enhancement

Unleashing the Potential of Aluminum Plating: A Comprehensive Solution for Metal Surface Enhancement

- Customized at your needs

- Aluminum Electroplating

- Customized at your needs

- Informations

- Description

Unleashing the Potential of Aluminum Plating: A Comprehensive Solution for Metal Surface Enhancement

Unleashing the Potential of Aluminum Plating: A Comprehensive Solution for Metal Surface Enhancement

What is Aluminum Plating?

Key Advantages of Aluminum Plating

Advantage | Description |

Enhanced Corrosion Resistance | Aluminum plating forms a dense, protective oxide layer that shields the underlying metal from moisture, chemicals, and environmental elements, significantly extending the lifespan of components in harsh conditions. |

Improved Wear Resistance | The hard, durable aluminum coating reduces friction and abrasion, minimizing wear and tear on moving parts and enhancing the overall performance and longevity of mechanical components. |

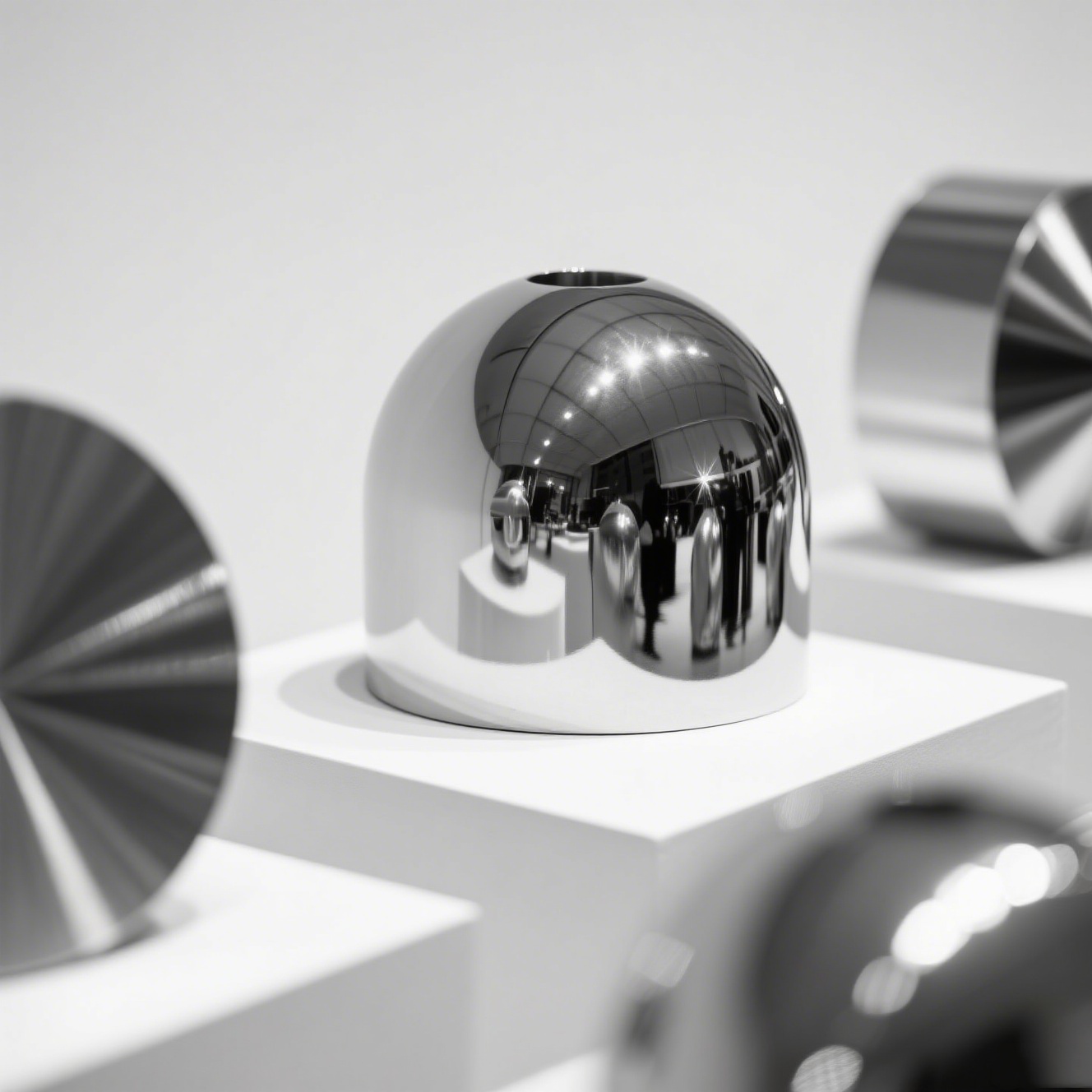

Exceptional Aesthetic Appeal | Aluminum plating offers a smooth, lustrous finish that can be customized to meet specific design requirements, enhancing the visual appeal of products and adding a touch of elegance and sophistication. |

Electrical and Thermal Conductivity | Aluminum is an excellent conductor of electricity and heat, making aluminum-plated components ideal for applications that require efficient electrical or thermal transfer, such as electronics and heat sinks. |

Cost-Effective Solution | Compared to other surface treatment methods, aluminum plating is a cost-effective solution that provides significant benefits without compromising on quality or performance. |

Versatile Applications

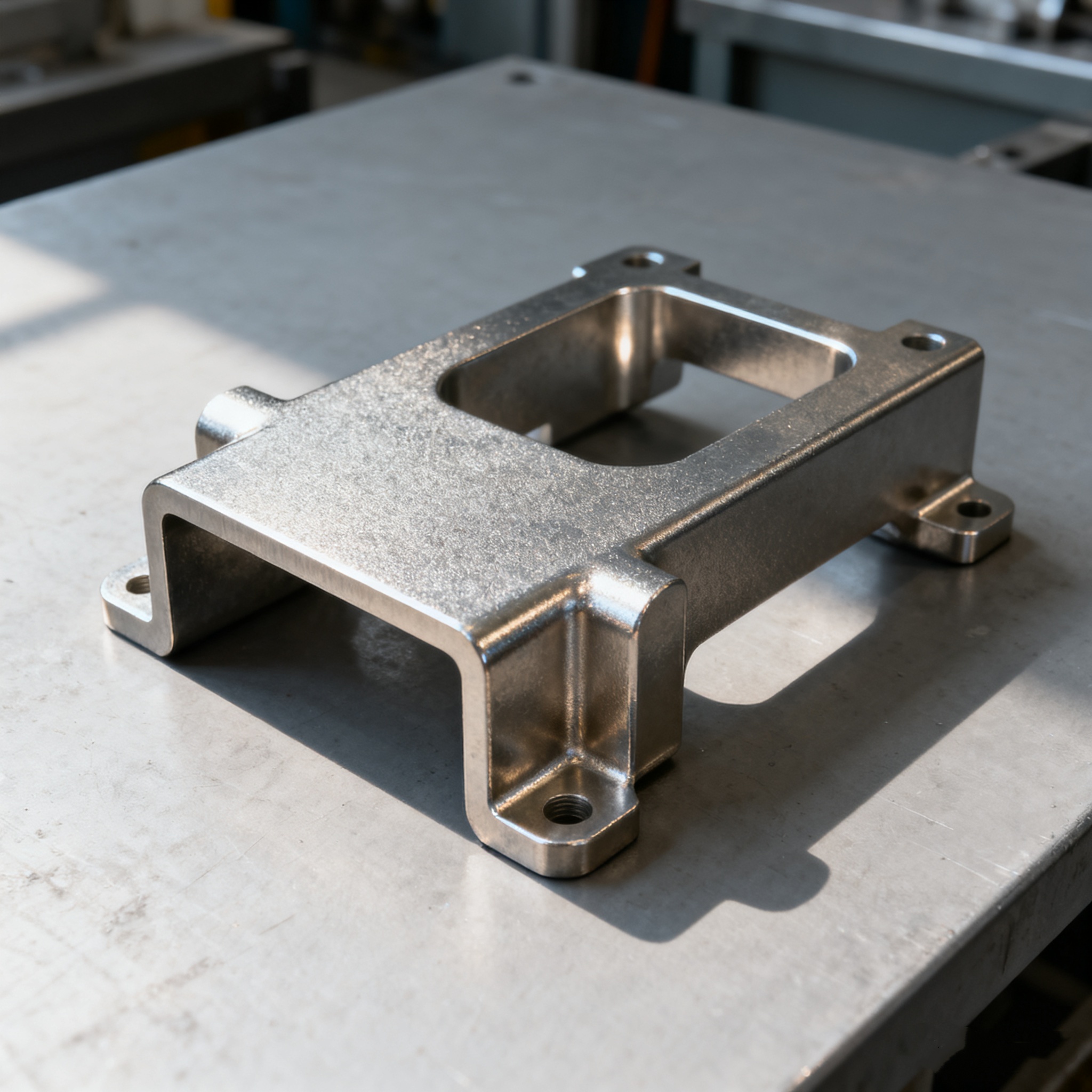

Automotive Industry: Aluminum plating is used to enhance the corrosion resistance and aesthetic appeal of automotive components, such as engine parts, wheels, and trim pieces.

Aerospace Industry: In the aerospace sector, aluminum plating is essential for protecting critical components from harsh environmental conditions and ensuring optimal performance and reliability.

Electronics Industry: Aluminum-plated components are widely used in electronics for their excellent electrical conductivity, thermal management capabilities, and electromagnetic shielding properties.

Consumer Goods: From smartphones and laptops to kitchen appliances and furniture, aluminum plating adds a touch of elegance and sophistication to consumer products while providing enhanced durability and functionality.

Medical Devices: Aluminum plating is used in the medical industry to improve the biocompatibility, corrosion resistance, and sterilization capabilities of medical devices, ensuring patient safety and comfort.

Processing Methods

Electroplating: This traditional method involves immersing the substrate in an electrolyte bath containing aluminum ions and applying an electric current to deposit the aluminum layer onto the surface.

Physical Vapor Deposition (PVD): PVD is a high-tech process that uses evaporation or sputtering to deposit a thin layer of aluminum onto the substrate in a vacuum chamber, resulting in a highly uniform and dense coating.

Chemical Plating: Also known as electroless plating, this method uses a chemical reaction to deposit the aluminum layer onto the substrate without the need for an external electric current, making it suitable for complex geometries and non-conductive materials.

Aluminum Plating vs. Anodizing

Feature | Aluminum Plating | Anodizing |

Coating Composition | A thin layer of aluminum is deposited onto the substrate. | A thick, porous oxide layer is formed on the surface of the aluminum. |

Corrosion Resistance | Excellent corrosion resistance, especially in harsh environments. | Good corrosion resistance, but may require additional sealing for optimal protection. |

Wear Resistance | High wear resistance, suitable for applications with high friction and abrasion. | Moderate wear resistance, can be improved with hard anodizing. |

Aesthetic Appeal | Offers a smooth, lustrous finish that can be customized with various colors and textures. | Provides a natural, matte finish with limited color options. |

Electrical and Thermal Conductivity | Maintains the electrical and thermal conductivity of the underlying metal. | Reduces electrical conductivity due to the insulating nature of the oxide layer. |

Cost | Generally more expensive than anodizing, but offers superior performance and durability. | More cost-effective, but may require additional post-treatment for enhanced properties. |

Why Choose Aluminum Plating?

Superior Corrosion Resistance: Aluminum plating provides unparalleled protection against corrosion, making it ideal for applications in harsh environments where rust and degradation are major concerns.

Enhanced Wear Resistance: The hard, durable aluminum coating significantly reduces friction and abrasion, extending the lifespan of components and minimizing maintenance costs.

Customizable Aesthetics: With a wide range of colors, textures, and finishes available, aluminum plating allows you to create products that stand out from the competition and meet your specific design requirements.

Versatile Applications: Aluminum plating can be applied to a variety of substrates, including metals, plastics, and ceramics, making it a versatile solution for a wide range of industries and applications.

Cost-Effective Solution: Despite its superior performance and durability, aluminum plating is a cost-effective solution that provides significant long-term savings compared to other surface treatment methods.

Trust in Our Expertise

| Type | Aluminum Electroplating | Entrance size | Customized at your needs |