Laser Cutting: The Ultimate Precision Solution for Your Manufacturing Needs

Laser Cutting: The Ultimate Precision Solution for Your Manufacturing Needs

- Customized at your need

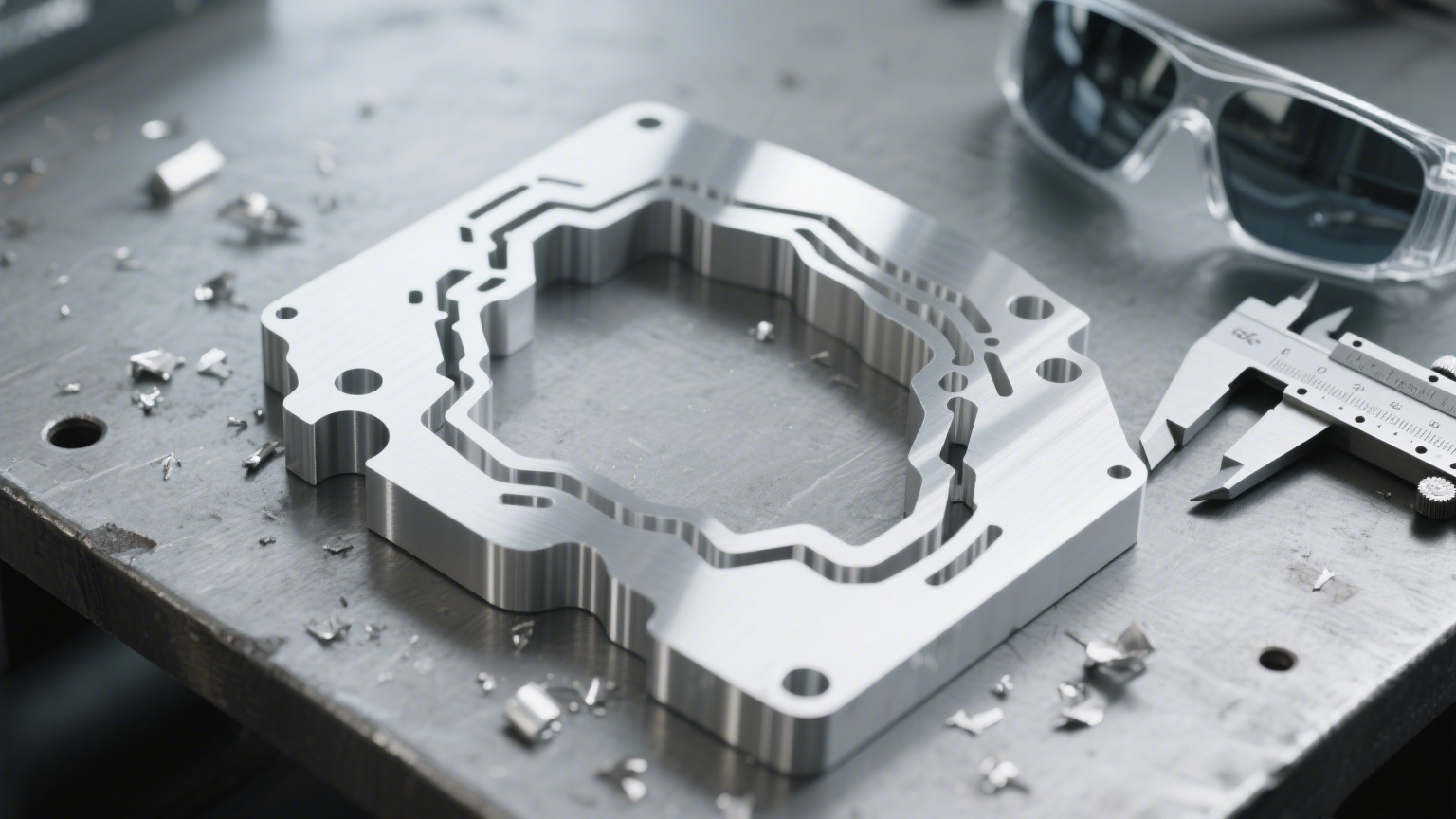

- Laser Cutting

- Customized at your need

- Informations

- Description

Laser Cutting: The Ultimate Precision Solution for Your Manufacturing Needs

Laser Cutting: The Ultimate Precision Solution for Your Manufacturing Needs

What Makes Our Laser Cutting Stand Out?

Unrivaled Technical Prowess: Equipped with state-of-the-art fiber laser systems (1000W to 15000W), we handle projects of all scales with consistent accuracy. Our automated nesting software reduces material waste by up to 30%, lowering your production costs without compromising quality.

Beyond Basic Cutting: We integrate laser marking, engraving, and micro-jointing into a single workflow, ideal for products requiring serialized tracking or complex assembly. For example, medical instrument manufacturers benefit from our ability to cut 0.1mm micro-slots and engrave 2D barcodes in one pass.

Material Mastery: From heat-sensitive plastics (like PEEK) to high-tensile alloys (such as Inconel 718), our variable power settings prevent warping or discoloration. We've even developed specialized processes for cutting reflective materials (e.g., copper) without damaging the laser source.

Material Category | Material Examples | Max Thickness | Cutting Speed (at 50% power) | Tolerance Range | Surface Roughness (Ra) |

Ferrous Metals | Mild Steel, Stainless Steel 316 | 30mm | 12m/min (mild steel, 10mm) | ±0.001mm | 0.8μm |

Non-Ferrous Metals | Aluminum 6061, Copper, Brass | 15mm | 8m/min (aluminum, 5mm) | ±0.002mm | 1.2μm |

High-Performance Alloys | Titanium Grade 5, Inconel 718 | 10mm | 5m/min (titanium, 3mm) | ±0.0015mm | 1.0μm |

Polymers & Composites | Acrylic, PEEK, Carbon Fiber | 25mm (acrylic) | 20m/min (acrylic, 5mm) | ±0.003mm | 0.5μm (acrylic) |

Wood & Organic Materials | Plywood, MDF, Leather | 30mm (plywood) | 18m/min (MDF, 10mm) | ±0.005mm | 2.0μm |

Who Benefits Most?

Aerospace: Cut lightweight aluminum honeycomb structures with ±0.005mm alignment for aircraft interiors.

Electronics: Produce 0.5mm-thick stainless steel shrouds for circuit boards with burr-free edges to prevent short circuits.

Automotive: Rapid-prototype custom gear components from 4140 steel, with turnaround times as fast as 24 hours for small batches.

Art & Architecture: Create 3D-formed metal sculptures with laser-cut precision joints that fit together without welding.

| Type | Laser Cutting | Entrance size | Customized at your need |