Hardware parts for medical equipment

2024-02-27

As a strategic partner of a global leading medical device manufacturer, we are deeply engaged in the customization of medical

-grade precision hardware parts, providing full-process precision manufacturing services for it. With outstanding manufacturing

strength and professional capabilities, we are honored to be among the core suppliers of top medical device enterprises in the

United States.

Relying on the ISO 13485 international quality management system certification for medical devices and combining industry-leading

high-precision processing technology, we focus on the research and production of core products such as surgical instrument components,

implant accessories, and device structural parts. In terms of material selection, we strictly adopt high-end materials with excellent biocompatibility,

such as 316L medical-grade stainless steel and Ti-6Al-4V titanium alloy, to ensure product quality from the source.

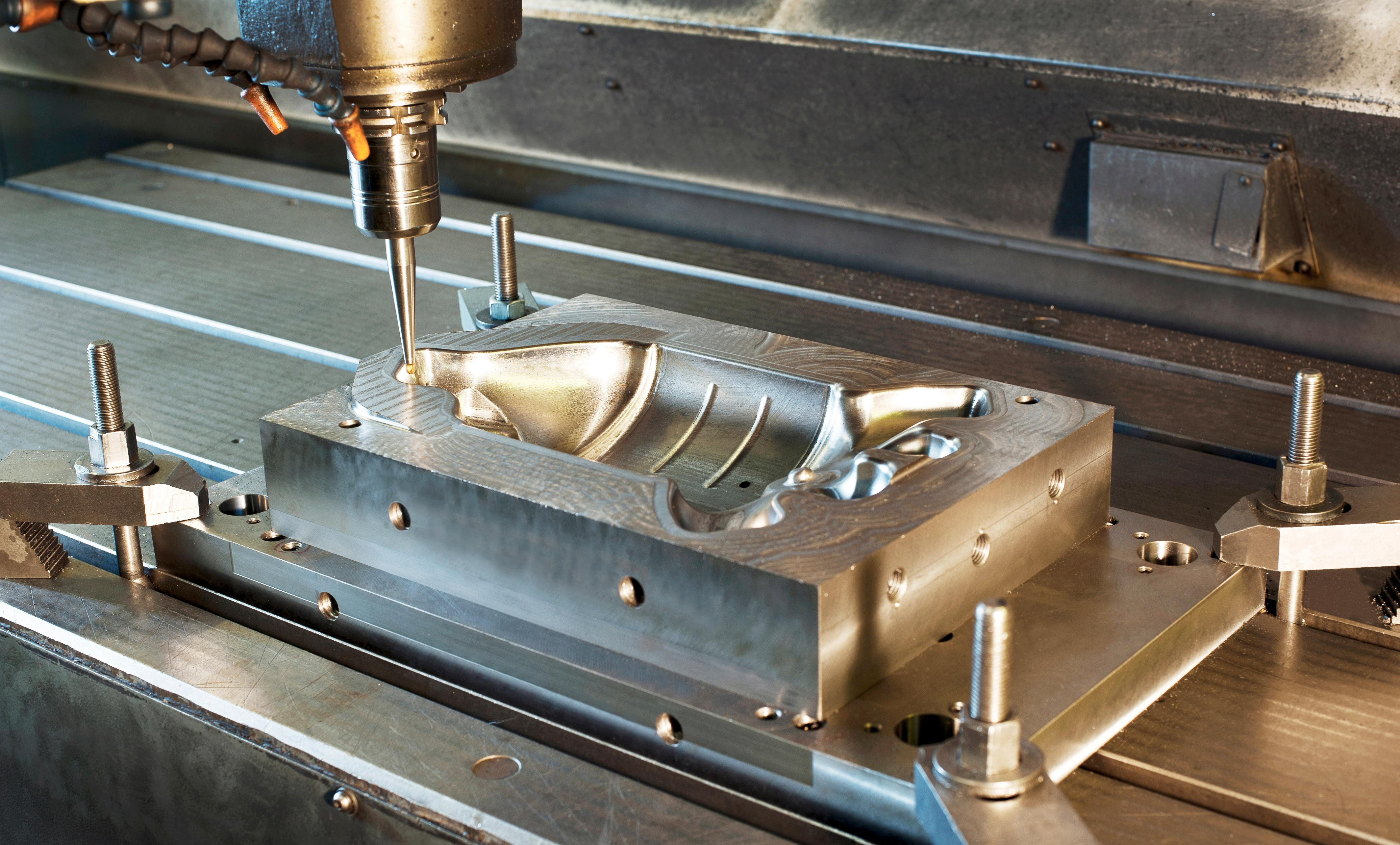

During the manufacturing process, we use five-axis simultaneous CNC machining and precision grinding processes to ensure that the dimensional

tolerance of products is controlled within ±0.005mm, and the surface roughness reaches the extremely high standard of Ra≤0.4μm. All products have

undergone ultrasonic deep cleaning and EO sterilization treatment, fully meeting the requirements of international authoritative certifications such as

FDA and EU CE. With superior quality, we create safe and reliable medical device solutions for our customers, contributing to the development of the

global medical and healthcare industry.