CNC Turning

CNC Turning

- Customized

- CNC Turning

- Customized

- Informations

- Description

CNC Turning

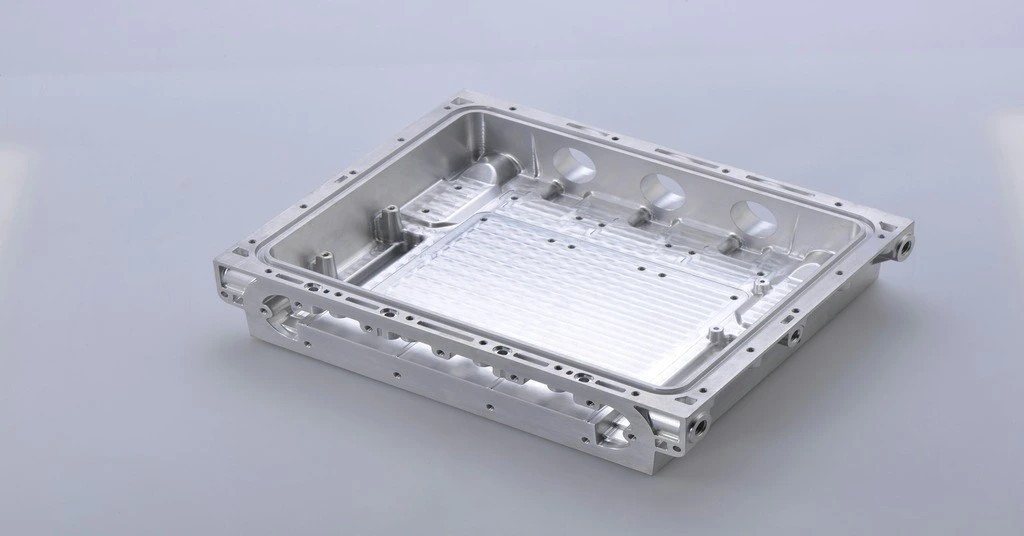

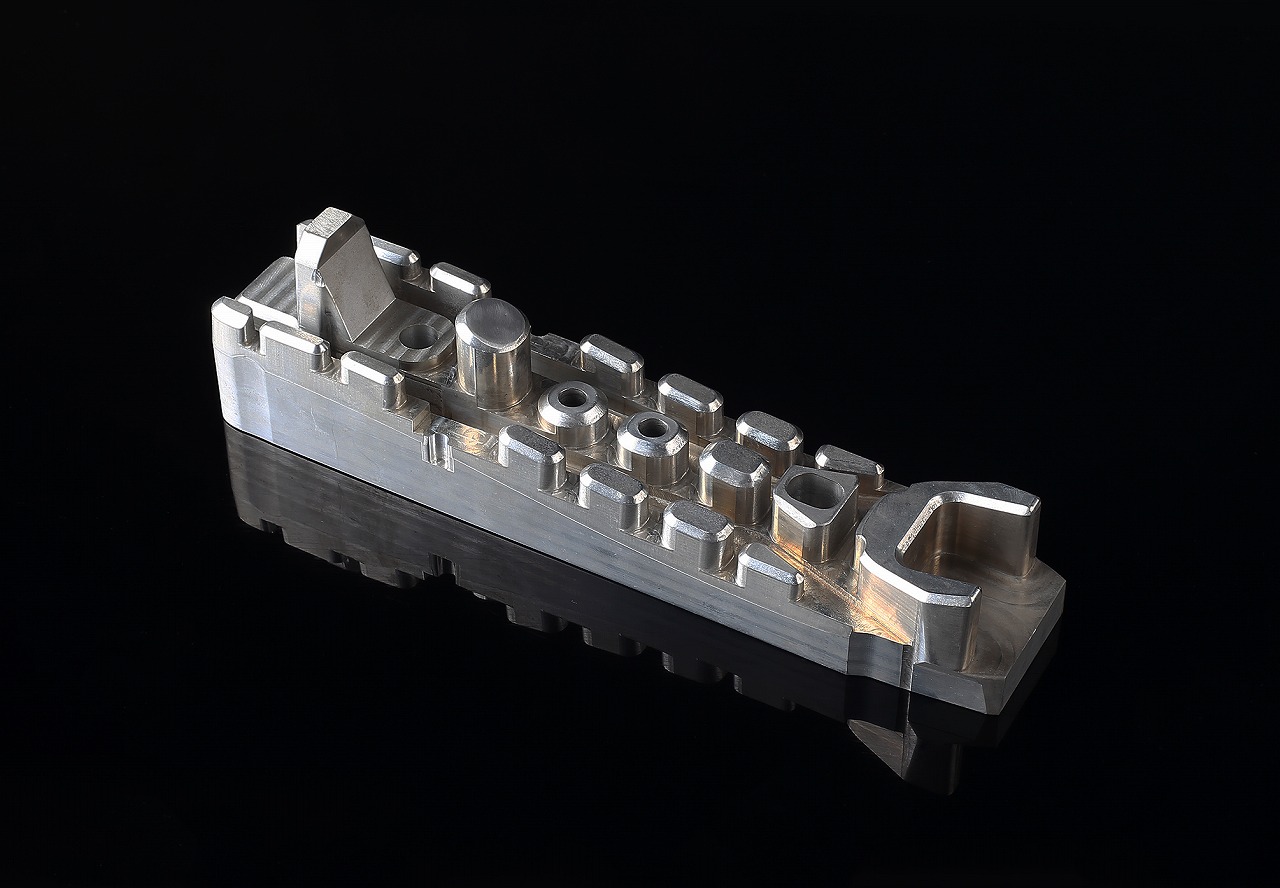

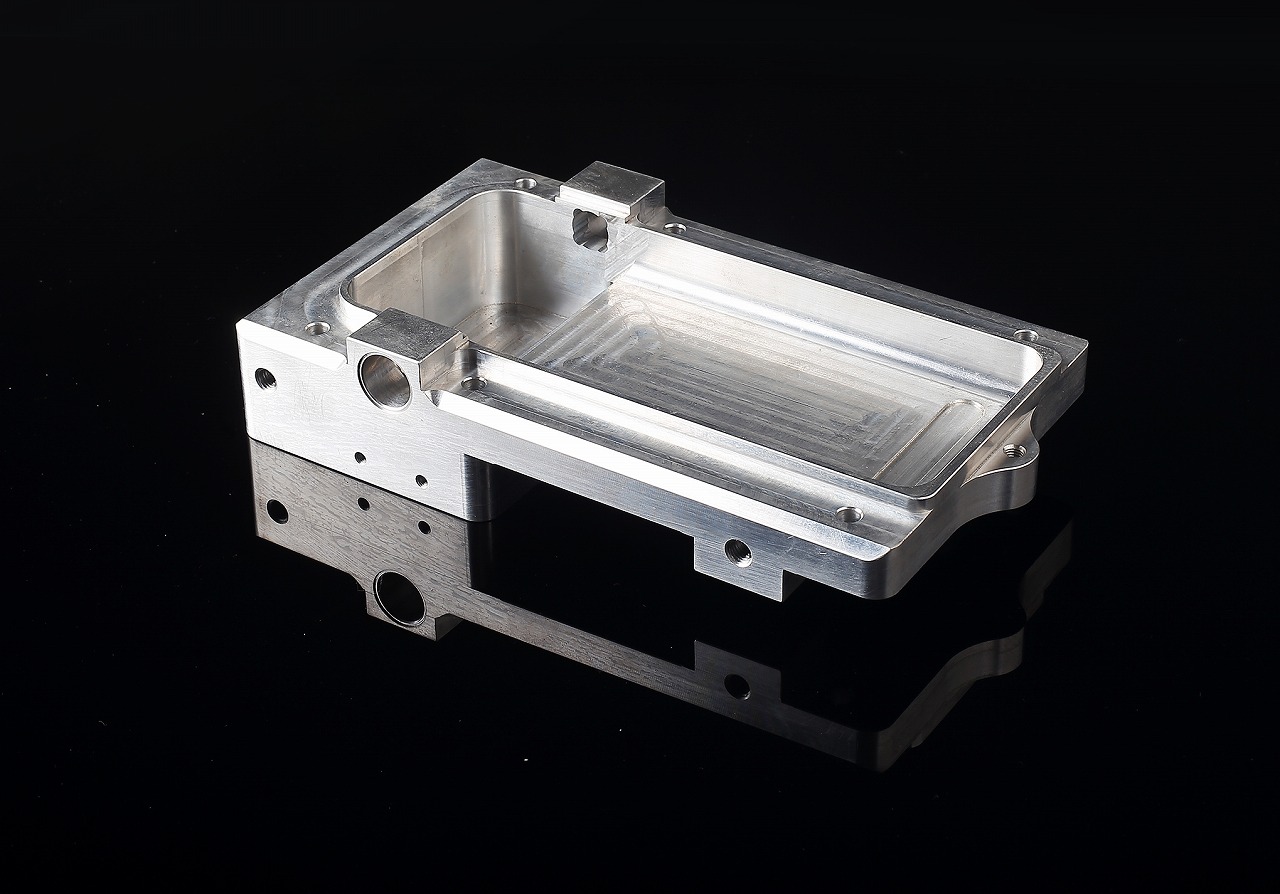

ShanFeng is a professional factory specializing in aluminum hardware processing.

Our comprehensive processing services cover a wide range of techniques, including CNC machining, welding, laser cutting,

anodizing, forging, casting, polishing, painting, and more.

The products showcased on this website merely represent a fraction of the processing services we offer to our clients.

Should you have any requirements in this regard, please provide CAD drawings. We will review them and respond to you

as promptly as possible.

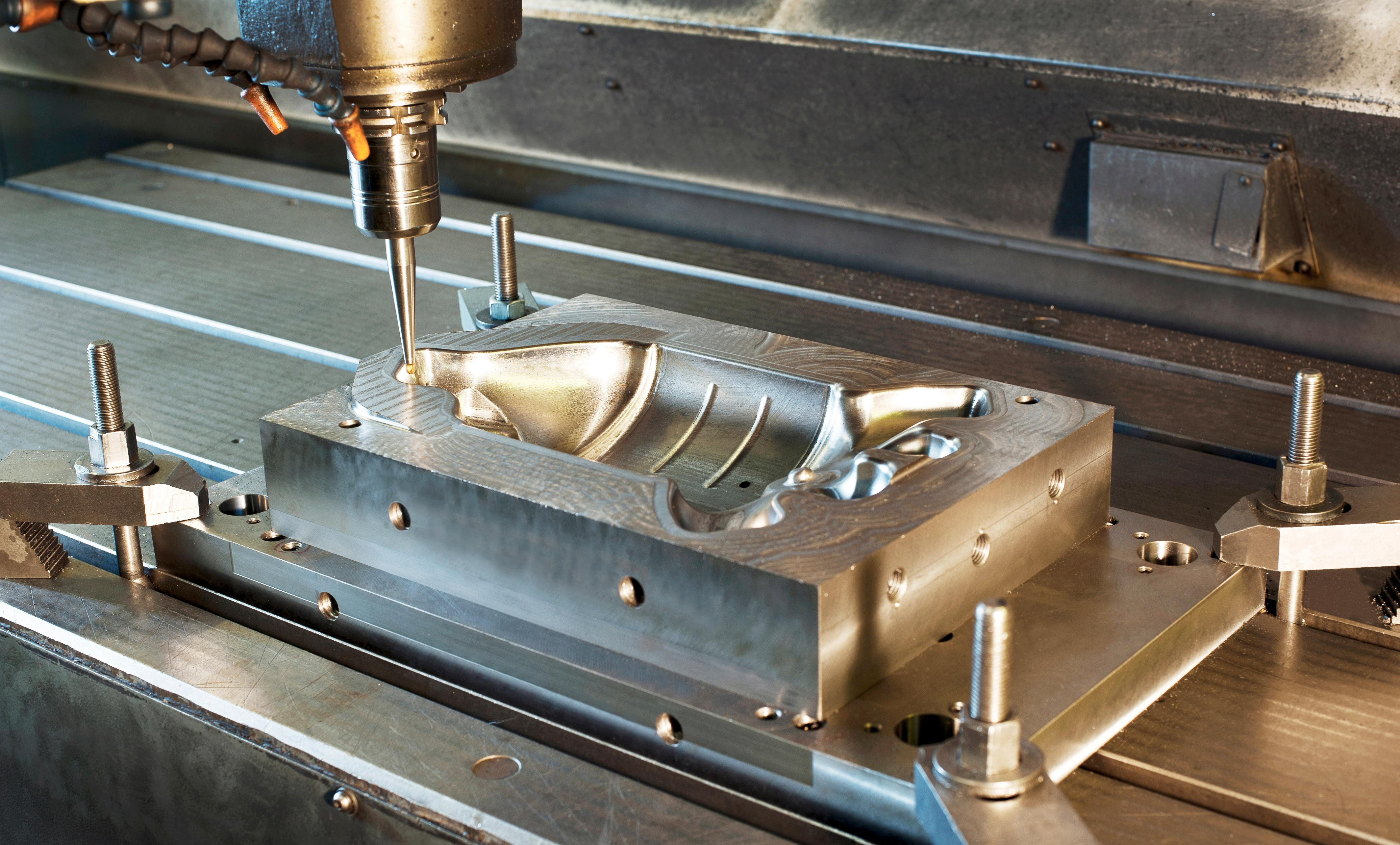

CNC Turning is a specific type of CNC Machining, referring to the particular subtractive machining process where the final piece,

or material, is spun at high speed and a cutting tool shaves away material. However, unlike the more commonly used CNC milling technique,

CNC turning uses one of the oldest styles and forms of manufacturing.

What is the process of turning?

Turning is the name given to the manufacturing process where bars of raw material is held and rotated at high speed. As the piece rotates, a cutting tool is fed to the piece, which works at the material, cutting away to create the desired shape. Unlike other cutting styles where the cutting tools themselves move and spin, in this case, the workpiece is rotated during the cutting process.

CNC Turning is commonly used for cylindrical shaped workpieces, however, it can be used for square or hexagonal-shaped raw materials.

The workpiece is held in place by a “chuck”. The"chuck"spins at varying RPMs (rotations per minute).

Unlike a traditional lathe, today's machines are numerically controlled. Often the turning process is under constant supervision and adjustment.

Meticulous and exact results are possible due to the lathe being consistently monitored by a computer program. Modern CNC Turning machines

have various tools, spindles, and speed capabilities. Additionally, the different sizes and shapes of the cutting tools themselves mean a wide range

of geometries are possible. Tubular and circular shapes benefit the most from CNC Turning techniques.

What is the difference between CNC Milling and Turning?

There are some fundamental core differences between CNC Milling and Turning. The core mechanisms differ, meaning some processes will be more

suited to milling or turning, respectively.

Factors that will affect this include:

Shape and size of the part

Material in use

The volume of parts required

Finish required

Budget

| Type | CNC Turning | Entrance size | Customized |