Aluminum CNC Machining: Forging Sci-Fi-Level Precision

Aluminum CNC Machining: Forging Sci-Fi-Level Precision

- Customized at your needs

- CNC Machining

- Customized at your needs

- Informations

- Description

Aluminum CNC Machining: Forging Sci-Fi-Level Precision

Aluminum CNC Machining: Forging Sci-Fi-Level Precision

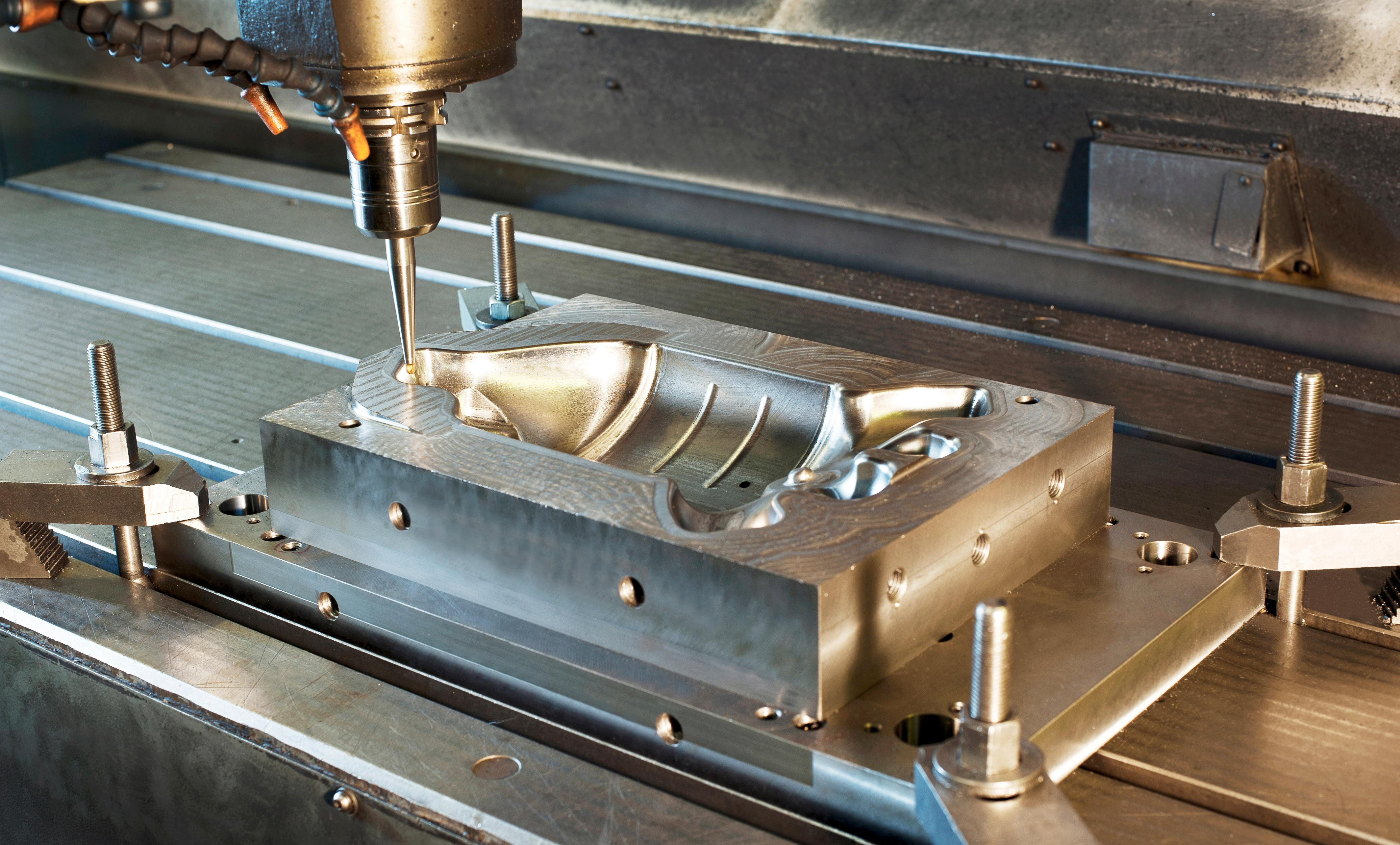

Rewriting the Rules of Machining

The Futuristic Machining Process

Stage | Operation | Game - Changing Advantages |

1. Meta - Material - Based Design | Using simulations that model the behavior of meta - materials to optimize the design of aluminum parts. This allows us to create components with unique properties, like enhanced strength or conductivity. | Enables the production of parts with 200% better performance in specific applications compared to standard designs, opening up new possibilities for product development. |

2. Cybernetic Toolpath Generation | Employing AI systems with cybernetic algorithms to generate toolpaths. These algorithms analyze the material properties of the aluminum and the desired end - product, creating the most efficient and precise machining routes. | Reduces machining time by 50% while increasing the complexity of the parts we can produce, giving you faster turnaround times and more intricate designs. |

3. Real - Time Adaptive Machining | Equipping our CNC machines with a network of sensors and actuators that can detect changes in the aluminum material during machining, such as variations in hardness. The machines then automatically adjust the machining parameters to maintain precision. | Ensures a 99.9% accuracy rate, even when working with inconsistent raw materials, and minimizes the risk of errors or defective products. |

4. Holographic Quality Assurance | Using holographic projection technology to inspect the machined parts. This allows our quality control team to view the parts from all angles in 3D, detecting even the smallest imperfections that might be missed with traditional inspection methods. | Catches 100% of critical defects, ensuring that only the highest - quality parts leave our factory and giving you complete peace of mind. |

Why Team Up with Us?

Futuristic Technology Stack: Our combination of meta - material simulations, cybernetic algorithms, and holographic inspection places us light - years ahead of the competition, enabling us to offer truly revolutionary machining solutions.

Unprecedented Versatility: From the most complex aerospace components to the most delicate medical parts, our real - time adaptive machining and cybernetic toolpath generation allow us to handle any project with ease.

Lightning - Fast Delivery: With reduced machining times and efficient processes, we can get your products to market in record - breaking time, giving you a significant competitive advantage.

Impeccable Quality: Our holographic quality assurance and real - time error - correction systems ensure that every aluminum part we produce meets the highest standards of quality and precision.

Step into the Future of Manufacturing

| Type | CNC Machining | Entrance size | Customized at your needs |