Revolutionizing Aluminum Polishing

Revolutionizing Aluminum Polishing

- Customized at your needs

- Aluminum Polishing

- Customized at your needs

- Informations

- Description

Revolutionizing Aluminum Polishing

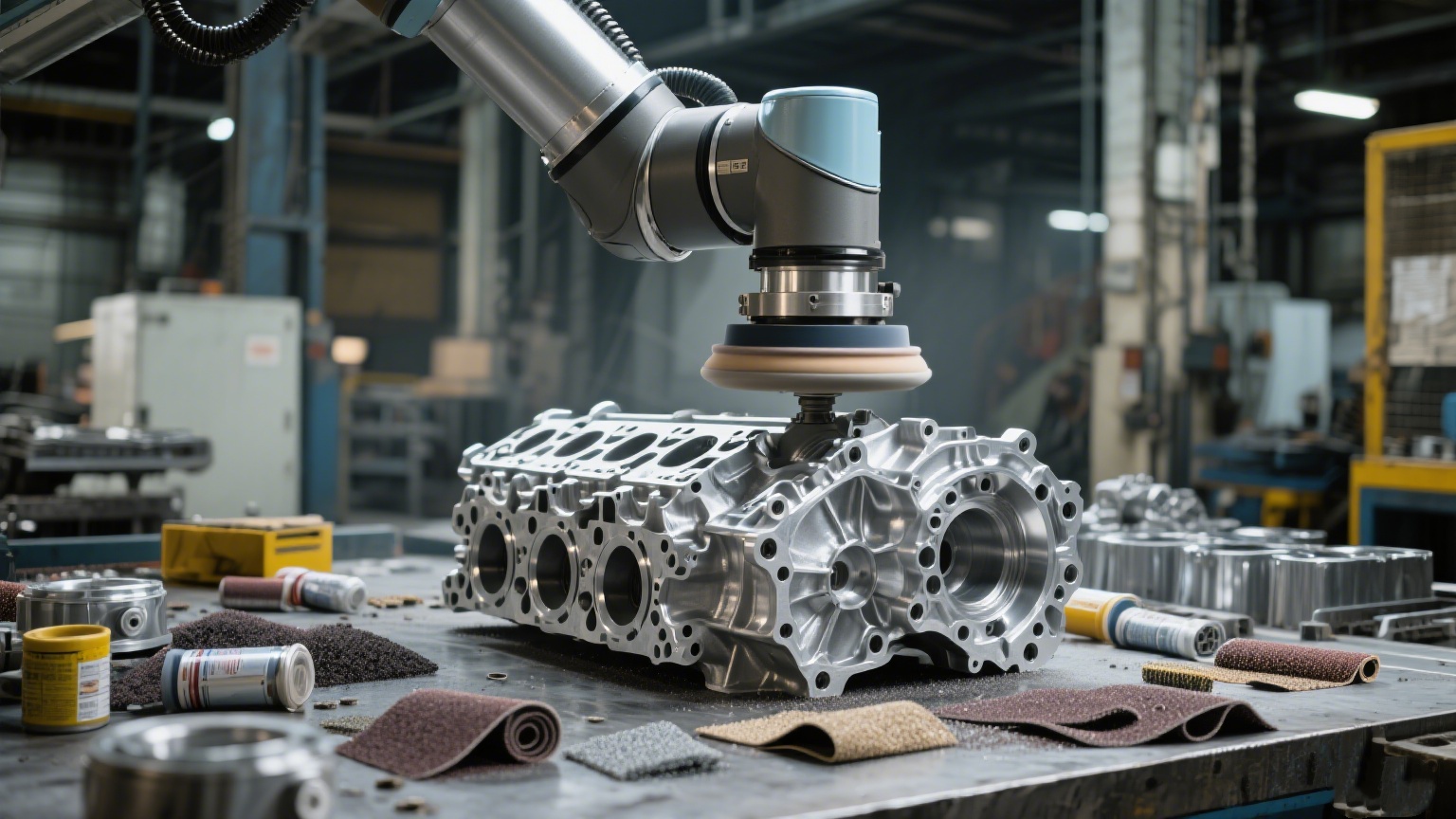

Revolutionizing Aluminum Polishing: Precision, Performance, and Unrivaled Expertise

Redefining the Art of Aluminum Polishing

Unmatched Features of Our Aluminum Polishing

Feature | In-Depth Explanation |

Ultra-Precision Machining | Our factory is equipped with the latest computer numerical control (CNC) polishing machines, capable of achieving tolerances as low as 0.001mm. This level of precision ensures that even the most complex aluminum parts are polished to perfection, meeting the strictest specifications of our clients. |

Advanced Surface Finishing | We offer a wide range of surface finishes, from mirror-like high gloss to subtle satin textures. Our proprietary finishing processes not only enhance the aesthetic appeal of the aluminum parts but also improve their corrosion resistance and durability, making them suitable for a variety of applications. |

Customized Solutions | We understand that every project is unique, which is why we offer customized aluminum polishing solutions tailored to the specific needs of our clients. Whether it's a small batch of prototype parts or a large-scale production run, our team works closely with you to develop a polishing strategy that meets your requirements and exceeds your expectations. |

Environmentally Friendly Processes | At ShanFeng, we are committed to sustainability. Our aluminum polishing processes are designed to minimize waste and reduce our environmental impact. We use eco-friendly polishing compounds and recycling systems to ensure that our operations are as green as possible. |

Key Benefits of Choosing Our Aluminum Polishing Services

Enhanced Aesthetics: Our polished aluminum parts add a touch of elegance and sophistication to any product. Whether it's a high-end consumer electronic device, a luxury automotive component, or a architectural feature, our polishing services can transform ordinary aluminum into a work of art.

Improved Performance: A smooth, polished surface reduces friction and wear, improving the performance and lifespan of aluminum parts. This is particularly important for components used in high-stress applications, such as aerospace and automotive engines.

Increased Productivity: Our advanced polishing equipment and efficient processes enable us to deliver high-quality results in a timely manner. This means shorter lead times and faster turnaround for your projects, allowing you to get your products to market faster.

Cost-Effective Solutions: By investing in the latest technology and optimizing our processes, we are able to offer competitive pricing without compromising on quality. Our goal is to provide you with the best value for your money, ensuring that your investment in aluminum polishing pays off in the long run.

Critical Considerations in Aluminum Polishing

Material Selection: The quality of the aluminum alloy used can have a significant impact on the polishing process and the final result. It's important to choose a high-quality alloy that is suitable for the intended application and has the right properties for polishing.

Surface Preparation: Proper surface preparation is essential for achieving a smooth, consistent finish. This includes cleaning the surface to remove any dirt, grease, or contaminants, as well as sanding or grinding to remove any rough spots or imperfections.

Polishing Technique: There are several different polishing techniques available, each with its own advantages and disadvantages. The choice of technique will depend on the specific requirements of the project, such as the desired finish, the size and shape of the part, and the production volume.

Quality Control: A rigorous quality control process is essential to ensure that the polished aluminum parts meet the required specifications. This includes regular inspections during the polishing process, as well as final inspections before the parts are shipped to the client.

Wide Range of Applications

Automotive: Polished aluminum parts are commonly used in the automotive industry for applications such as wheels, engine components, and interior trim. Our high-quality polishing services can enhance the performance and appearance of these parts, giving your vehicles a competitive edge.

Aerospace: The aerospace industry requires the highest levels of precision and quality, and our aluminum polishing services are up to the challenge. We can polish aluminum parts for aircraft engines, wings, fuselages, and other critical components, ensuring that they meet the strictest aerospace standards.

Consumer Electronics: In the consumer electronics industry, appearance is just as important as performance. Our polished aluminum casings and components can add a touch of luxury and sophistication to your products, making them more appealing to consumers.

Medical: The medical industry demands the highest levels of cleanliness and precision, and our aluminum polishing services can help you meet these requirements. We can polish aluminum parts for medical devices, surgical instruments, and other healthcare products, ensuring that they are safe and effective for use.

Architecture: Polished aluminum is a popular choice for architectural applications due to its durability, corrosion resistance, and aesthetic appeal. Our aluminum polishing services can be used to create stunning architectural features, such as facades, railings, and decorative elements.

Why Choose ShanFeng for Aluminum Polishing?

Industry Expertise: With over 15 years of experience in the aluminum manufacturing industry, we have the knowledge and expertise to handle even the most complex polishing projects. Our team of experts has a deep understanding of the aluminum polishing process and can provide you with valuable insights and recommendations.

State-of-the-Art Facilities: Our factory is equipped with the latest and most advanced polishing equipment, allowing us to deliver high-quality results with precision and efficiency. We are constantly investing in new technology and equipment to stay ahead of the competition and meet the evolving needs of our clients.

Quality Assurance: Quality is our top priority, and we have a strict quality control process in place to ensure that every polished aluminum part meets our high standards. We use the latest inspection and testing equipment to verify the quality of our products, and we are committed to continuous improvement to ensure that we are always delivering the best possible results.

Customer Service: At ShanFeng, we believe that our success is directly related to the success of our clients. That's why we are committed to providing exceptional customer service at every stage of the project. From initial consultation to final delivery, our team of experts will work closely with you to ensure that your project is completed on time, within budget, and to your exact specifications.

| Type | Aluminum Polishing | Entrance size | Customized at your needs |